Forming method of no-material-head shaft piece by cross wedge rolling

A headless, cross wedge rolling technology, applied in metal rolling and other directions, can solve problems such as reducing material utilization rate, and achieve the effect of improving material utilization rate, reducing production cost and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0016] As shown in the figure, take a cylindrical blank, and use the mold shown in the attached figure to roll it into an output shaft in the form of one out of two. The specific process is as follows:

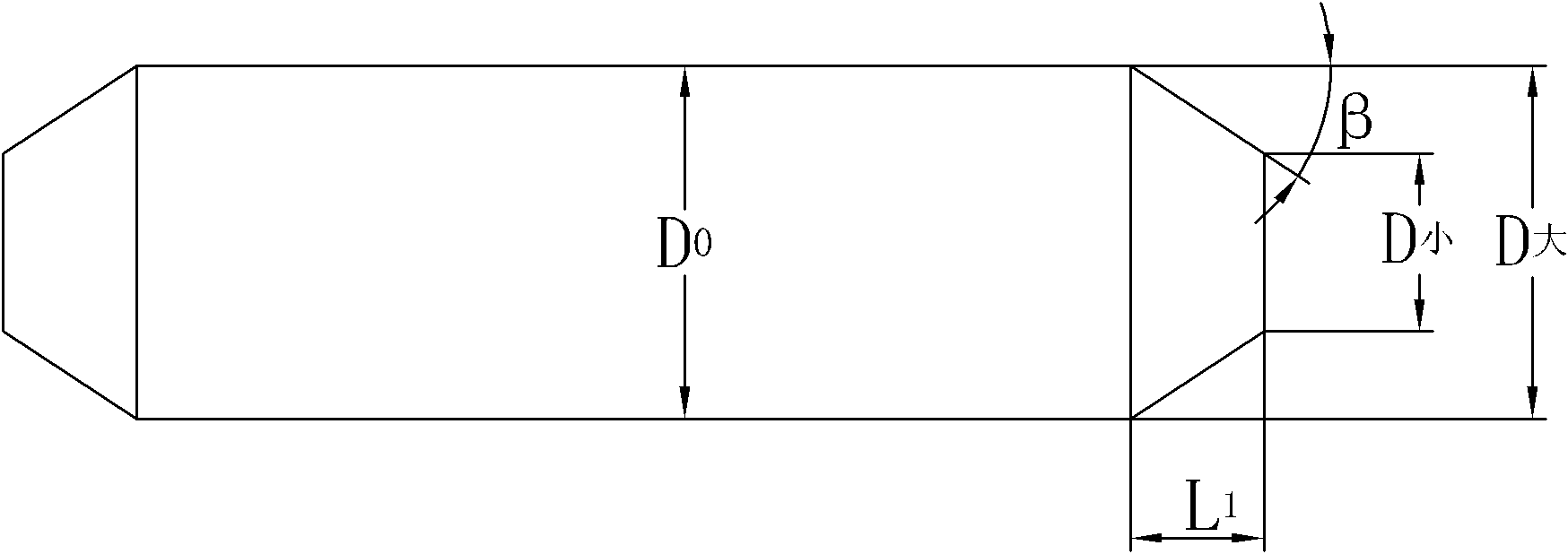

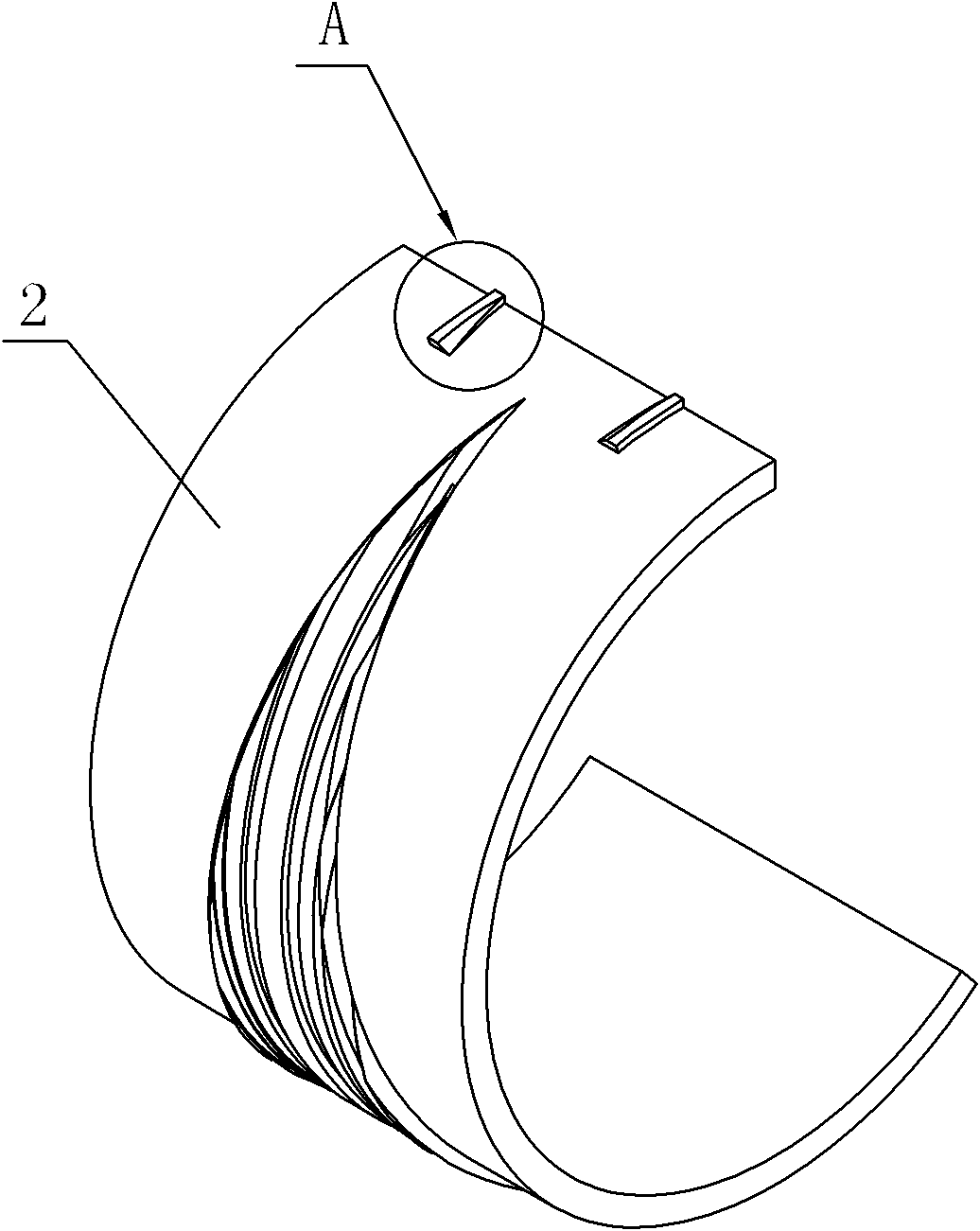

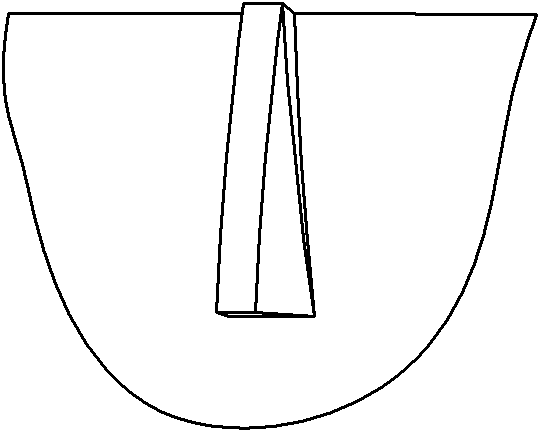

[0017] First design the outer diameter of the mold to be 800mm, and the forming angle of the mold to be 32 0 , widening angle is 8.5 0 , and then heat the cylindrical blank 1 to be rolled to 1200°C, and then send the blank 1 into the rolling die 2 through the axial feeding device on the cross wedge rolling mill for rolling. Part I of the mold 2 rolls both ends of the blank 1 into a linear truncated cone shape with the big end facing inward and the small end facing outward (such as figure 1 shown), and make the large head diameter of the linear frustum D 大 with the original diameter D of blank 1 0 Equal, the diameter of the small head of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com