Method for manufacturing bearing device and bearing device

A bearing device, bearing technology, applied to shafts and bearings, rigid supports of bearing components, bearings, etc., can solve the problems of separation of elastomer materials, weakening of mechanical connections, and reduction of shock absorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

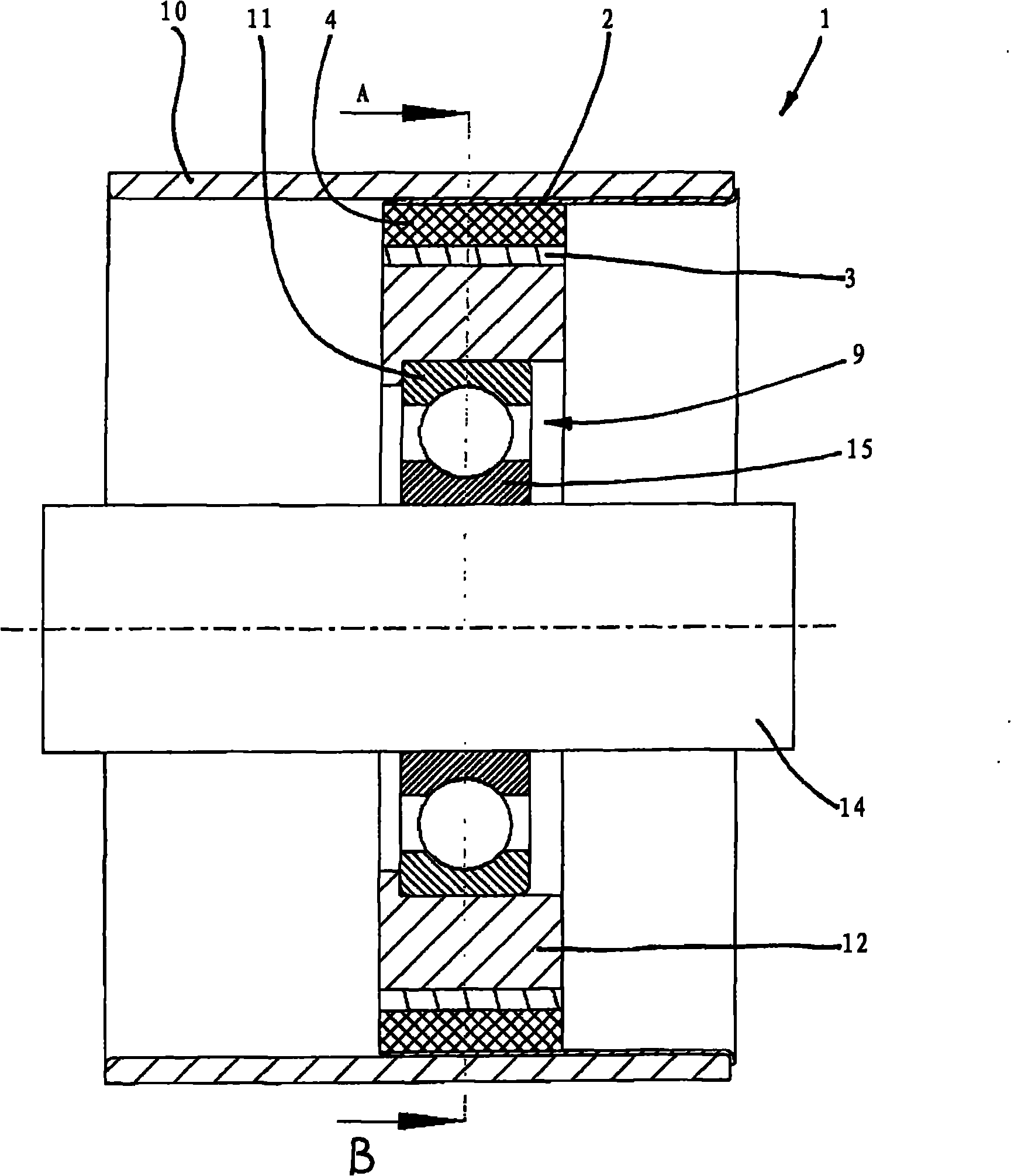

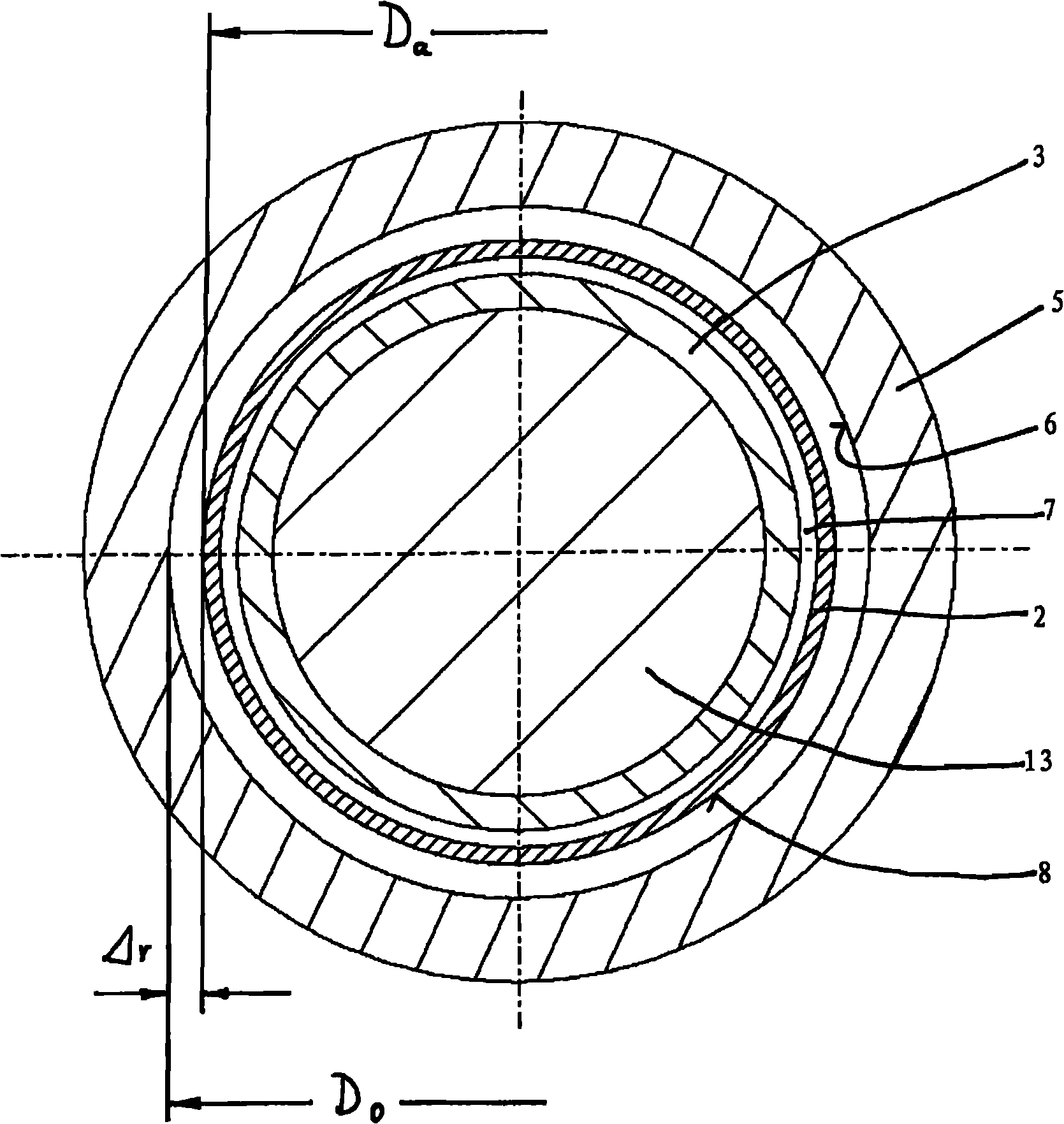

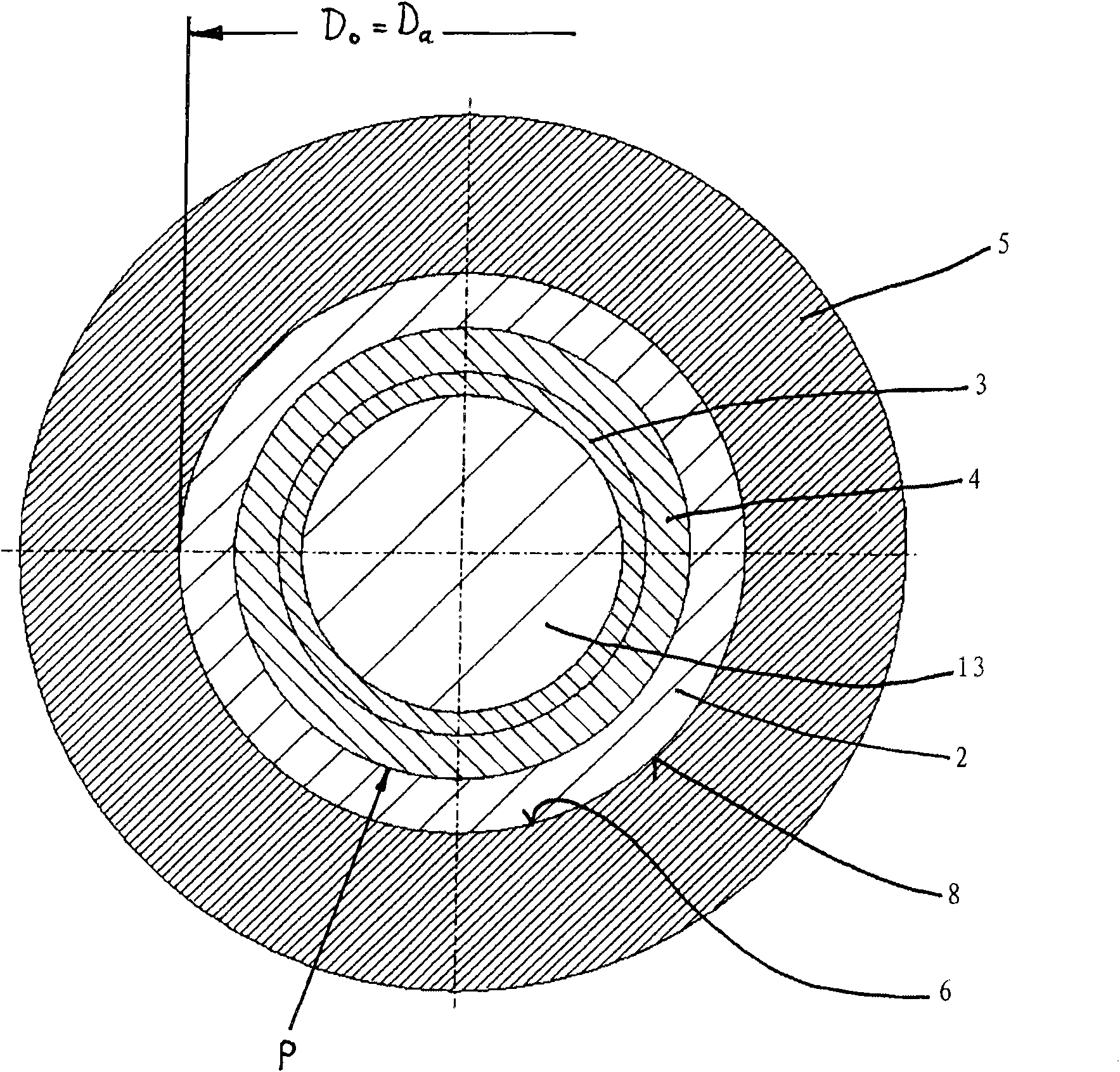

[0038] exist figure 1 In the radial section of , the bearing arrangement 1 can be seen, with which the support roller 10 , which is only partially shown, is supported relative to the shaft part 14 .

[0039] Bearings 9 in the form of deep groove ball bearings are used for this purpose. The inner ring 15 of the bearing is fixed on the shaft member 14 . The outer ring 11 is arranged in an intermediate carrier 12 which itself is located above the unit consisting of the first sleeve part 2 and the second sleeve part 3 with the ring 4 of elastomeric material arranged therebetween.

[0040] The first sleeve element 2 is fixedly connected to the support roller 10 , while the second sleeve element 3 is connected to the intermediate support 12 . Accordingly, a damping mounting of the support roller 10 relative to the shaft part 14 is formed by the ring 4 made of elastomer material, corresponding to constructions known per se.

[0041] A unit consisting of a first sleeve part 2 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com