Wallboard connection column and wall body for combined house

A technology for combining houses and connecting columns, applied in the direction of columns, walls, pier columns, etc., can solve the problems of low construction difficulty and high work efficiency, and achieve the effect of solving the problem of shrinkage joints, convenient house decoration, and firm connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

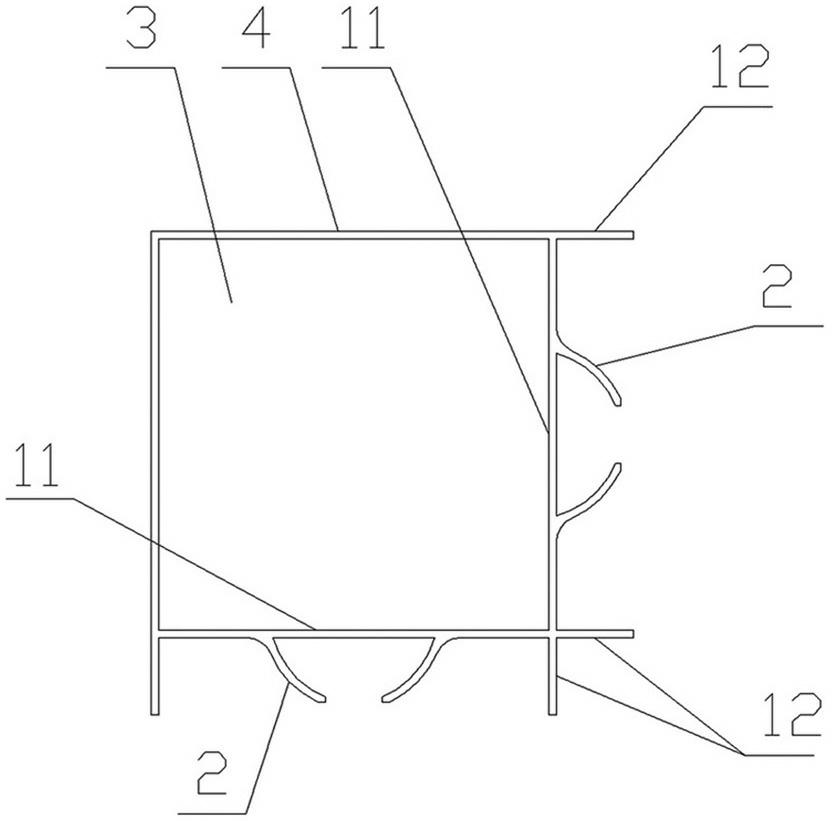

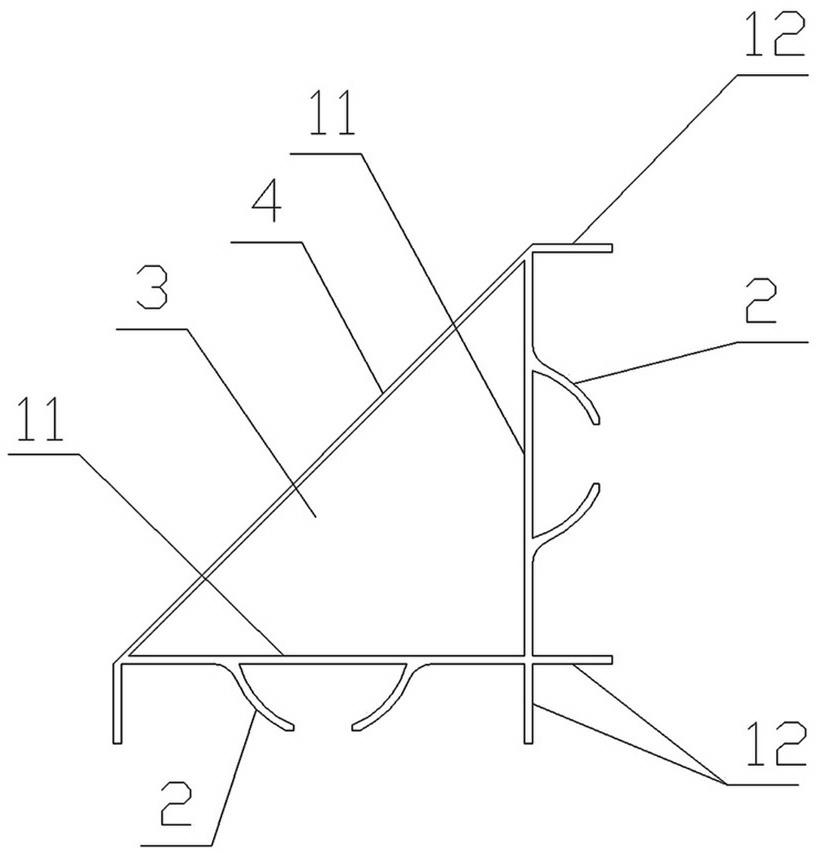

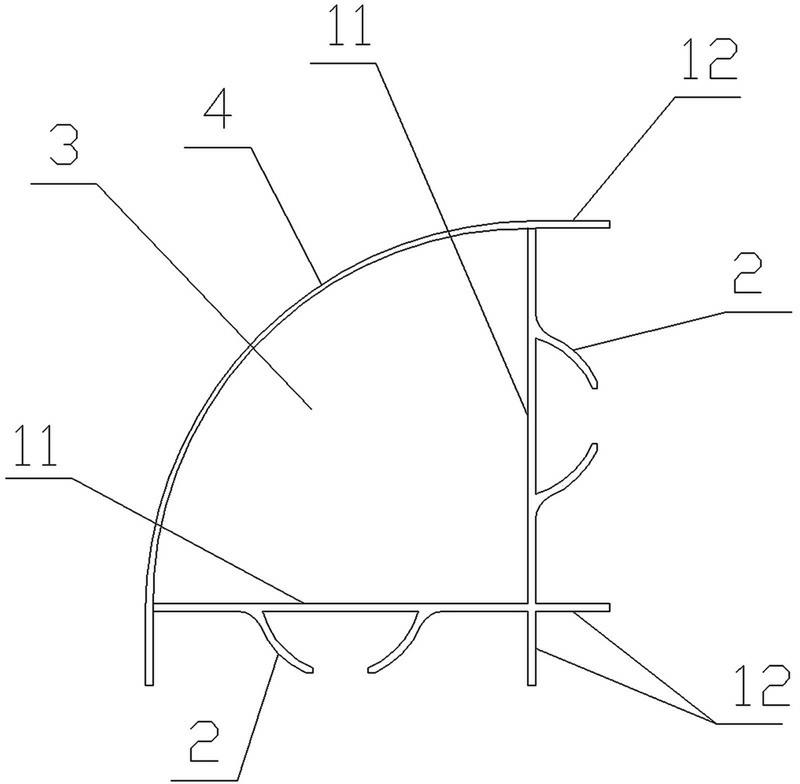

[0036] refer to Figure 1 to Figure 4 , a combined house wall panel connecting column has two U-shaped parts, the U-shaped part has a bottom 11 and a side part 12 and is formed by it to fit a rectangular groove at the end of the wall panel, and a bottom of the two U-shaped parts The 11 ends are vertically intersected, and the two sides of the connecting edge 4 are intersected with the other end of the bottom 11 of the two U-shaped parts. The connecting edge 4 can be designed as a straight plate (such as figure 2 ), rectangular plate shape (such as figure 1 ), curved plate shape (such as image 3 ) or irregular shape (such as Figure 4 ); connect the edge sealing 4 and the bottom 11 of the two U-shaped parts to form a pipe structure with a pipe 3 inside, and the middle section of the bottom 11 in the rectangular groove of each U-shaped part is provided with a snap-flap 2 , and the snap-flap 2 It is T-shaped, Π-shaped, octagonal or double-L-shaped. This embodiment only enum...

Embodiment 2

[0040] refer to Figure 6 , a combined house wall panel connecting column, has two U-shaped parts, the U-shaped part has a bottom 11 and a side part 12 and is formed by it to fit a rectangular groove at the end of the wall panel, and the two bottoms of the two U-shaped parts 11 are parallel and the directions of the notches of the rectangular grooves are opposite. The two ends of the bottom 11 of the two U-shaped parts are connected by the connecting edge 4 to form a pipe structure with a pipe 3 inside. The middle section of the bottom 11 of the rectangular groove of each U-shaped part There is a card wing plate 2 on the top, and the card wing plate 2 is T-shaped, Π-shaped, octagonal or double L-shaped. Present embodiment only enumerates eight shapes.

[0041] combined reference Figure 11 , using the wall of the linear composite house built in this embodiment, the method is the same as in Embodiment 1.

Embodiment 3

[0043] refer to Figure 7 , Figure 9 and Figure 10 , the present embodiment, as an optimization of embodiment 2, differs from embodiment 2 in that: the middle section of the bottom 11 of the two U-shaped parts is a circular arc segment, and the snap-wing plate 2 provided on the middle section of the bottom 11 of the U-shaped part has an eight-shaped ( Such as Figure 7 ), Π shape (such as Figure 9 ) and double L-shape (such as Figure 10 ).

[0044] The method of using the linear composite house wall built in this embodiment is the same as that in Embodiment 1.

[0045] Compared with embodiment 2, the space of the bonding area 7 in this embodiment is slightly smaller, which can reduce the amount of glue; the space of the pipeline 3 is larger, which is beneficial to the laying of electric wires or water pipes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com