Main driving and speed-changing system of drilling machine as well as operating mechanism of the drilling machine

A technology of operating mechanism and main transmission, which is applied to the drilling driving device, drilling equipment, earth-moving drilling, etc. in the wellbore, which can solve the problems of inconvenience and inability to realize automatic control, and achieve the effect of facilitating automatic control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

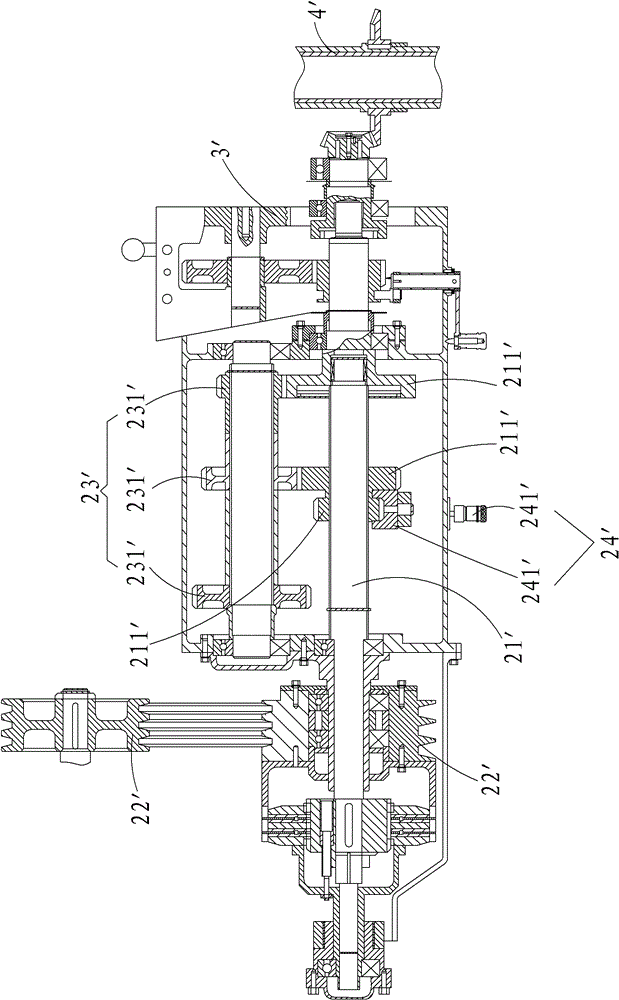

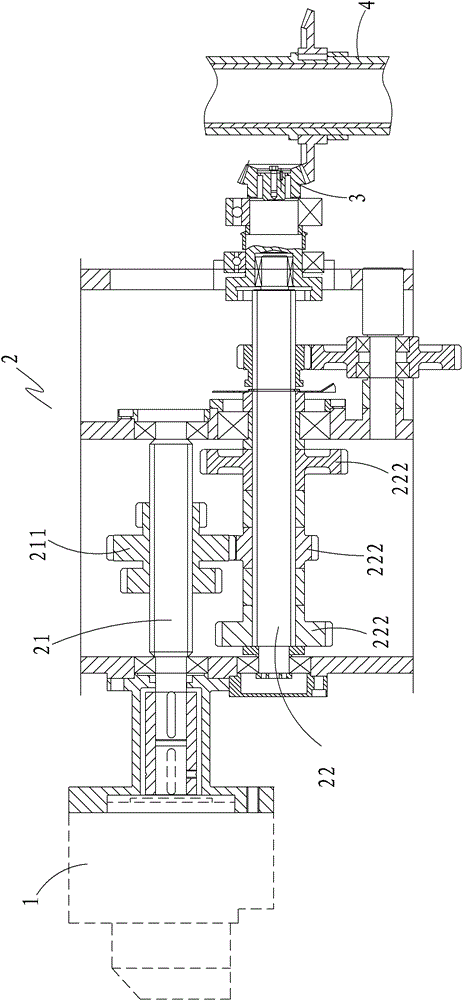

[0013] Such as Figure 2 to Figure 5 As shown, the main transmission and transmission system of the present invention is mainly used for power transmission inside the drilling rig, and the drilling rig includes a power source 1 (which may be an oil motor, but the present invention is not limited thereto), a main transmission and transmission system 2, Other transmission systems 3 and vertical shafts 4 for setting the drill. The main transmission and transmission system 2 and other transmission systems 3 jointly transmit the power of the power source 1 to the drilling tool on the vertical shaft 4 at different gear speeds.

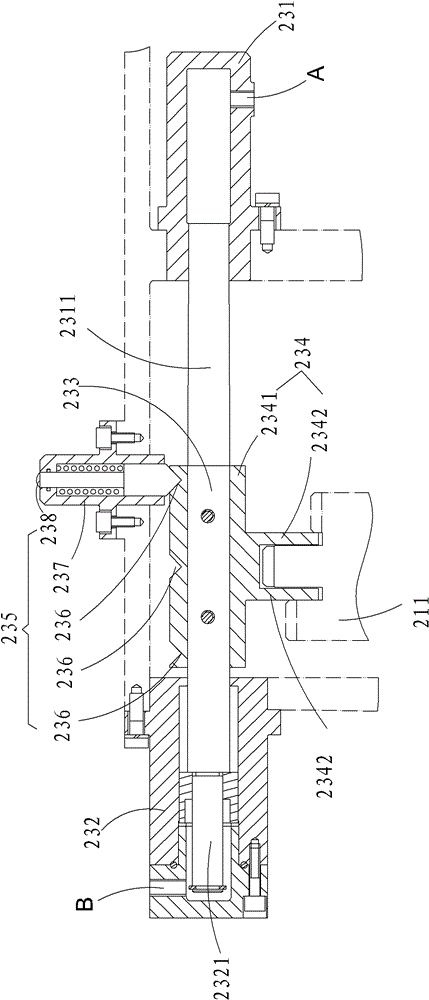

[0014] The main transmission and speed change system 2 of the present invention includes a driving shaft 21 connected to the power source 1, a driven shaft 22 arranged parallel to the driving shaft 21, and a shaft that can slide axially along the driving shaft 21 is arranged on the driving shaft 21. Sliding gear set 211, a plurality of fixed gears 222 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com