Fluid sensor

A fluid sensor and housing technology, applied in the field of fluid sensors, can solve problems such as oil supply waste and insufficient oil supply, and achieve the effects of preventing waste, simple and easy operation, and realizing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

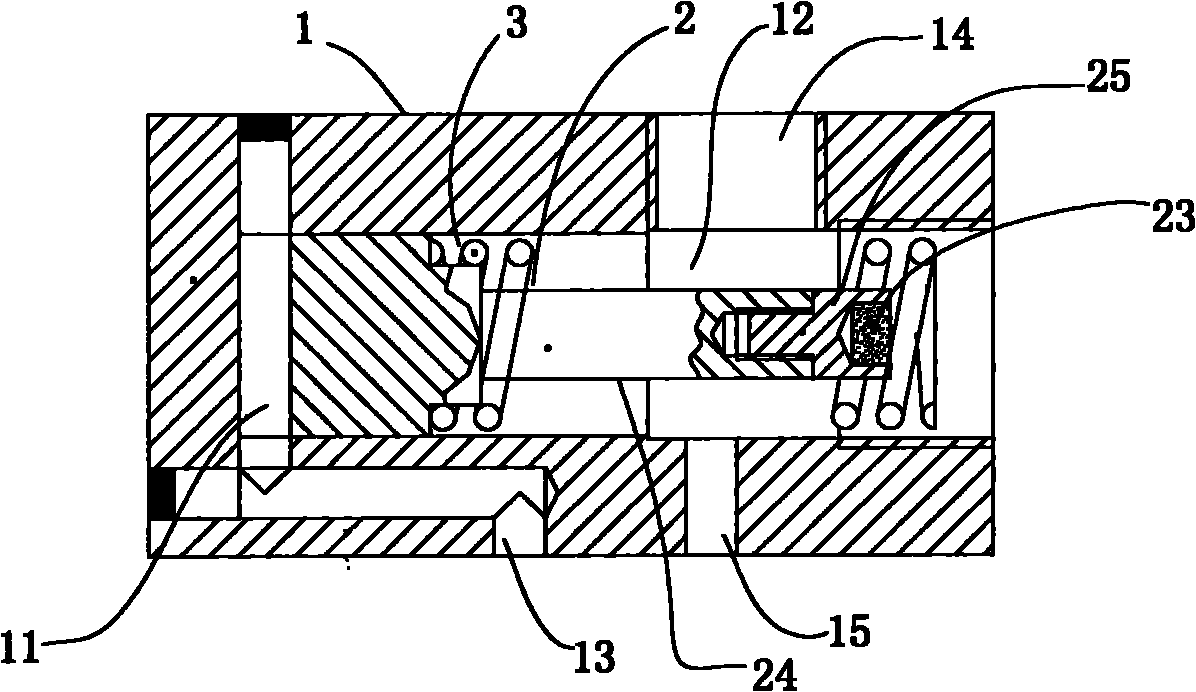

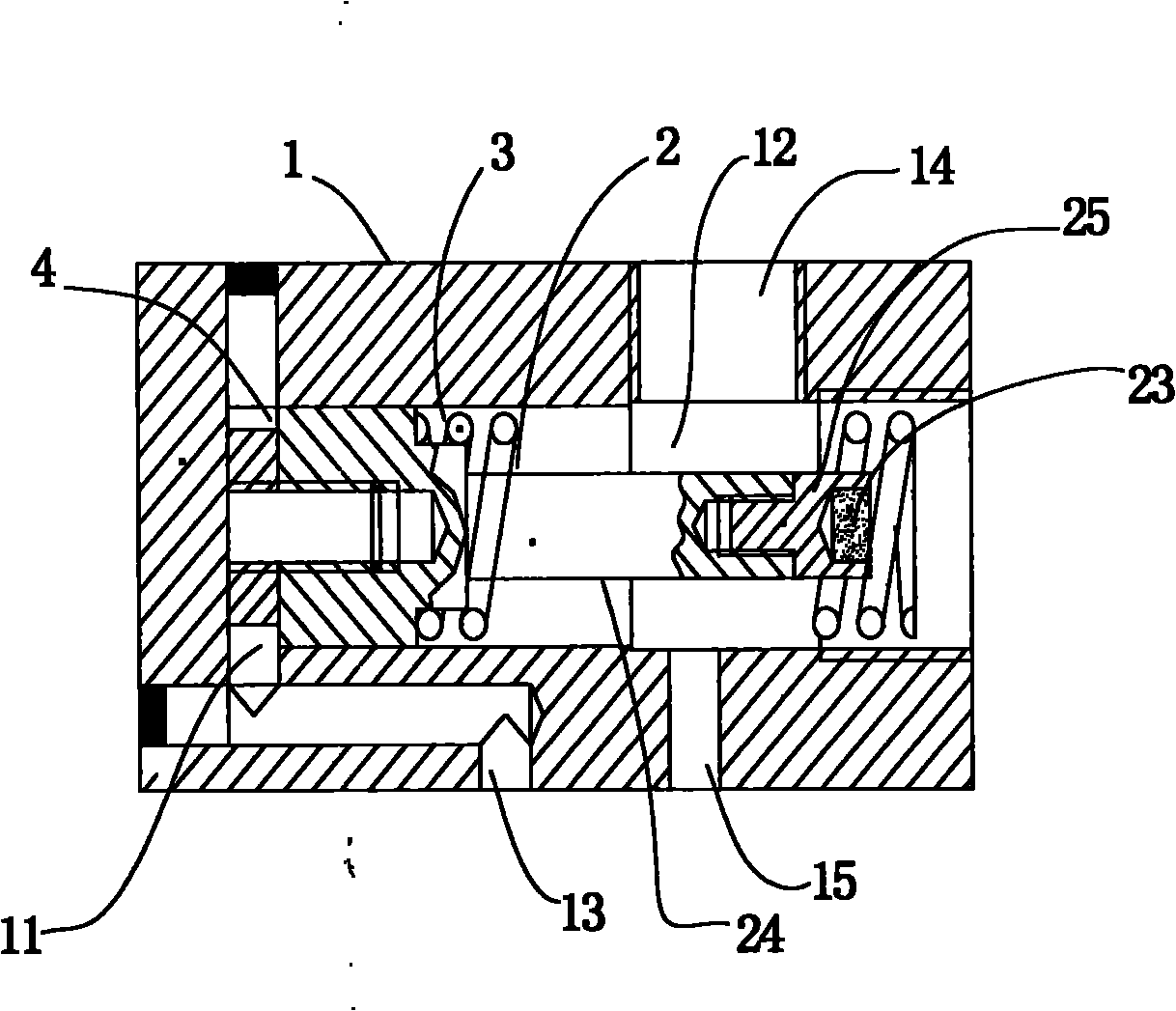

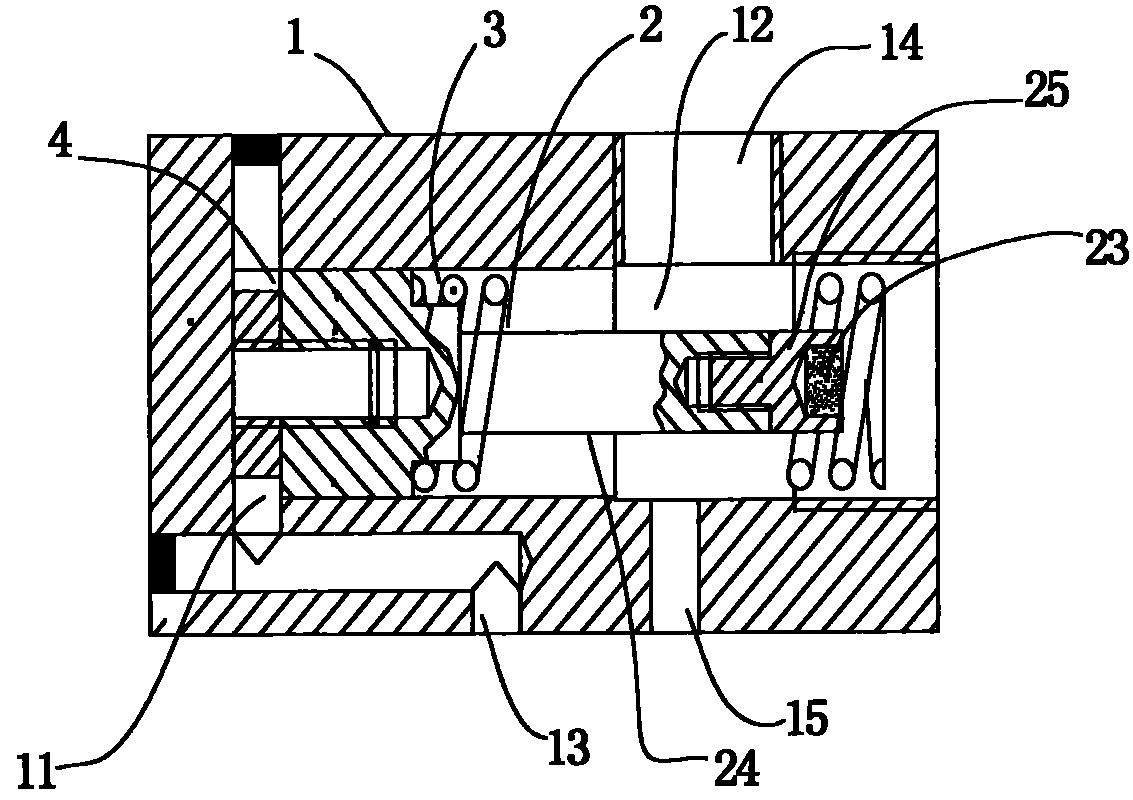

[0028] The structure of the fluid sensor of the present invention is as figure 1 As shown, it includes a housing 1, a piston 2 and a signal transmitter arranged in the housing 1, and the space surrounded by the housing 1 forms a cavity. The piston 2 is slidably disposed in the cavity, and divides the cavity into an inflow cavity 11 and an outflow cavity 12 . A resetting device 3 for resetting the piston 2 is also provided in the outflow chamber 12, an inductive element 23 is provided at an end of the piston 2 close to the signal transmitter, and an end of the housing 1 close to the inductive element 23 is connected to the The sensing element 23 is correspondingly fixed with a signal transmitter (not shown in the figure). The fluid sensor is also provided with a regulating device 4 for regulating the fluid flow.

[0029] The piston 2 of the fluid sensor is provided with a sealing groove, and an o-shaped sealing ring is installed in the sealing groove to prevent leakage. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com