Roll groove design method for seamless steel pipe stretch reducing machine set

A technology of tension reduction and seamless steel pipe, which is applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of uneven pass curve transition, difficulty in optimizing design, and affecting the quality of the outer surface of the product. The effect of improving quality and improving the efficiency of optimized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

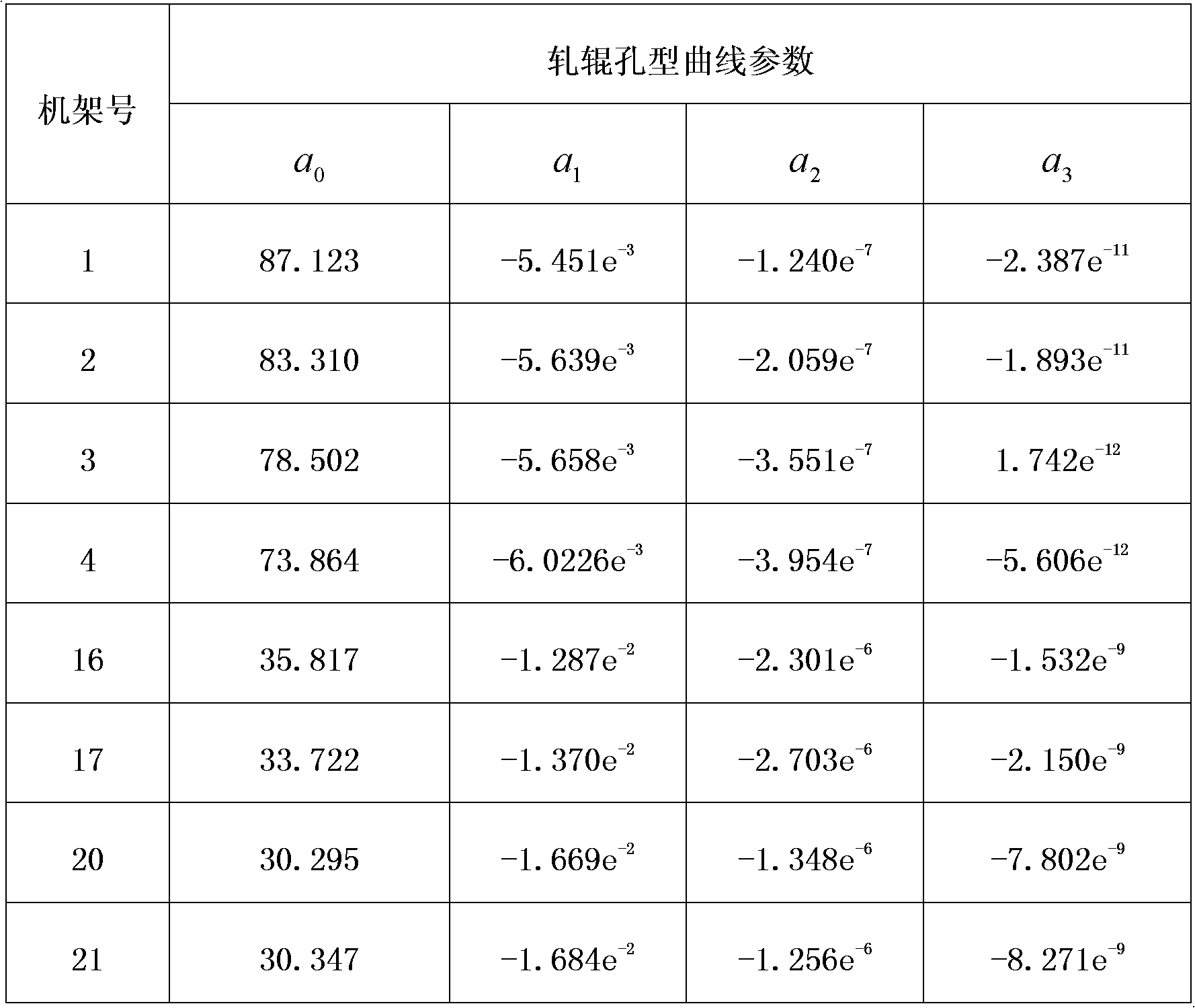

[0044] The design process and design results of the optimal design of the roll pass curve of a φ159 seamless steel pipe tension reducing unit using the above method.

[0045] designing process:

[0046] ①Collect the equipment parameters and range of varieties and specifications of the φ159 seamless steel pipe tension reducing unit.

[0047] The unit has 21 frames and a frame spacing of 300mm; the diameter of the inlet pipe of the tension reducing unit is 182mm, the wall thickness ranges from 3.5 to 25mm, the product diameter ranges from 48 to 180mm, and the yield strength ranges from 200 to 600Mpa.

[0048] ②The diameter of the product is mainly 89mm, 73mm, 60mm, the wall thickness is mainly 3mm, 4.5mm, 6mm, 10mm, the strength level is mainly 20# steel, 45# steel, then there are 3×4×2=24 A typical variety and specification product. The weighting coefficient of each specification product in this design is 1.

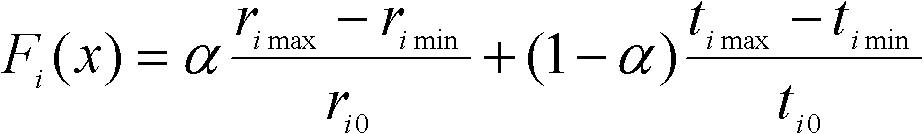

[0049] ③ with a 0 、a 1 、a 2 、a 3 is the pass curve parameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com