Framework column bending hysteresis test specimen with reusable stiffening bar sections

A technology of frame columns and rigid beams, applied in the field of experimental research on building structural components, can solve the problems of large waste and high cost, and achieve the effects of convenient construction, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

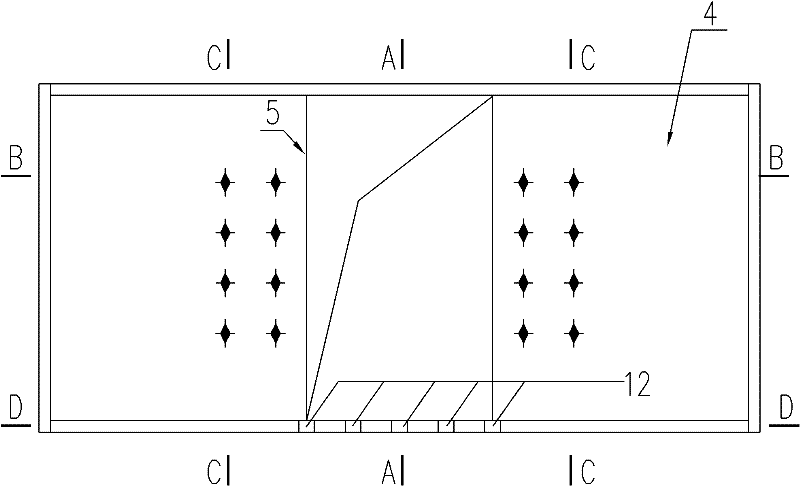

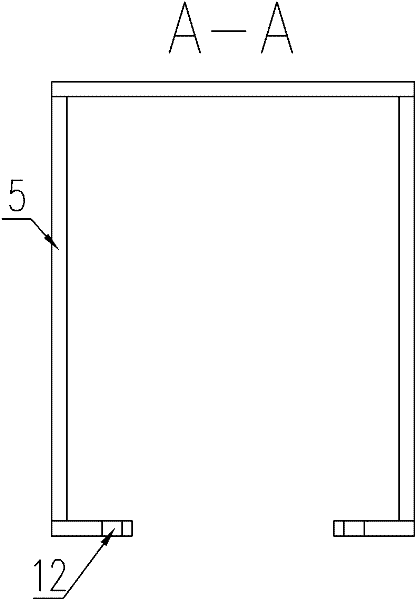

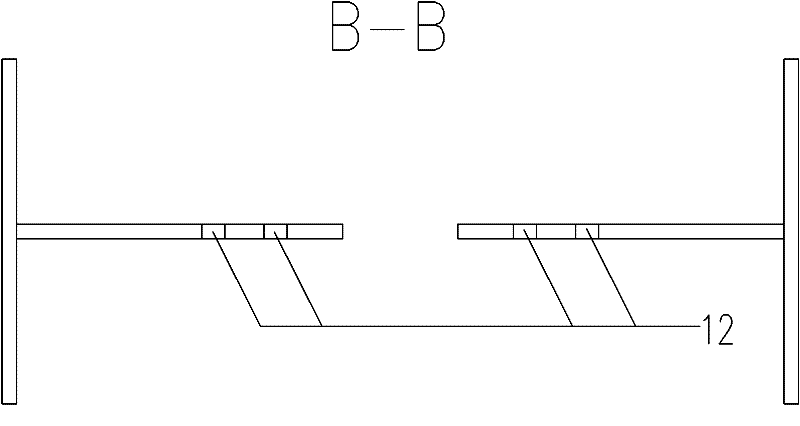

[0020] Specific implementation mode one: the following combination Figure 1~5 , Figure 6-9 and Figure 22Describe this embodiment in detail, the frame column compressive bending hysteresis test specimen with recyclable rigid beam section described in this embodiment includes a steel tube concrete column 1 and two rigid beam sections, and the upper and lower ends of the steel tube concrete column 1 are respectively installed There is a rigid beam section, and the test piece also includes two connecting ring plates 3 and four stiffening ear plates 6, each rigid beam section includes an I-shaped steel beam section 4, two stiffening webs 5 and a head cover Plate 13; two connecting ring plates 3 are scattered and centered and set on the steel tube concrete column 1 from top to bottom and welded together with the outer wall of the steel tube concrete column 1. The upper and lower end side walls of the steel tube concrete column 1 are each welded with a For (two) stiffening lugs ...

specific Embodiment approach 2

[0021] Specific implementation mode two: the following combination Figure 1~5 This embodiment will be specifically described. The connector 7 in this embodiment is a high-strength bolt. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: The cross-sectional shape of the concrete filled steel pipe column 1 in this embodiment is circular or polygonal. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com