Power socket with safety shielding device of power jack

A technology for safety baffles and power sockets, which is applied to the parts of the connection device, coupling devices, circuits, etc., can solve the problems of inconvenient assembly, easy deviation of the baffle, and complicated action mechanism, etc. Simple and reliable, stable motion track effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

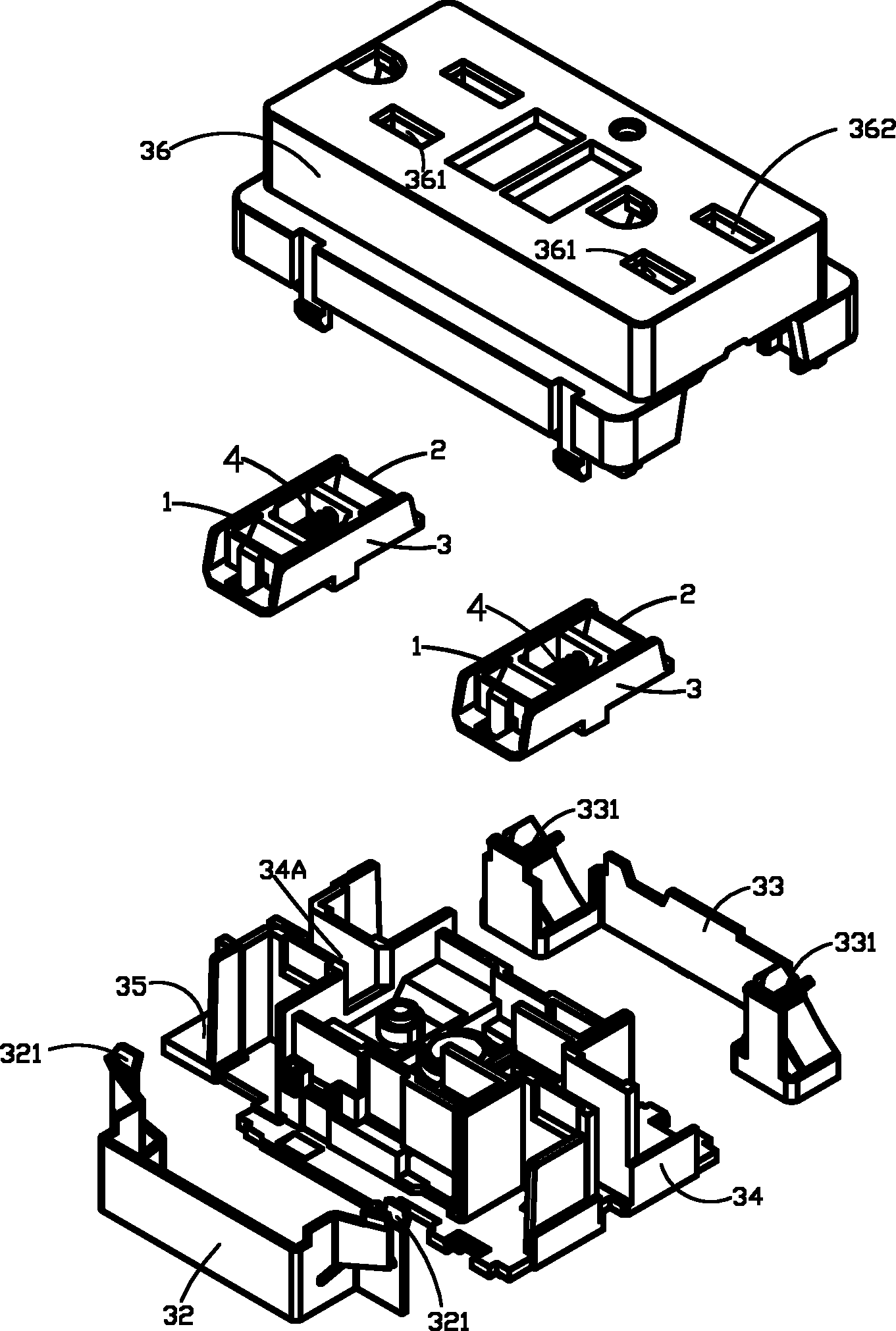

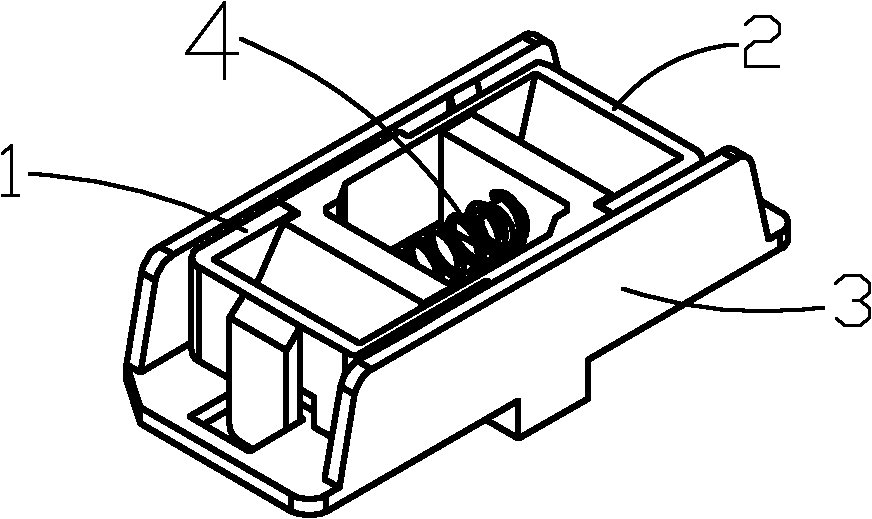

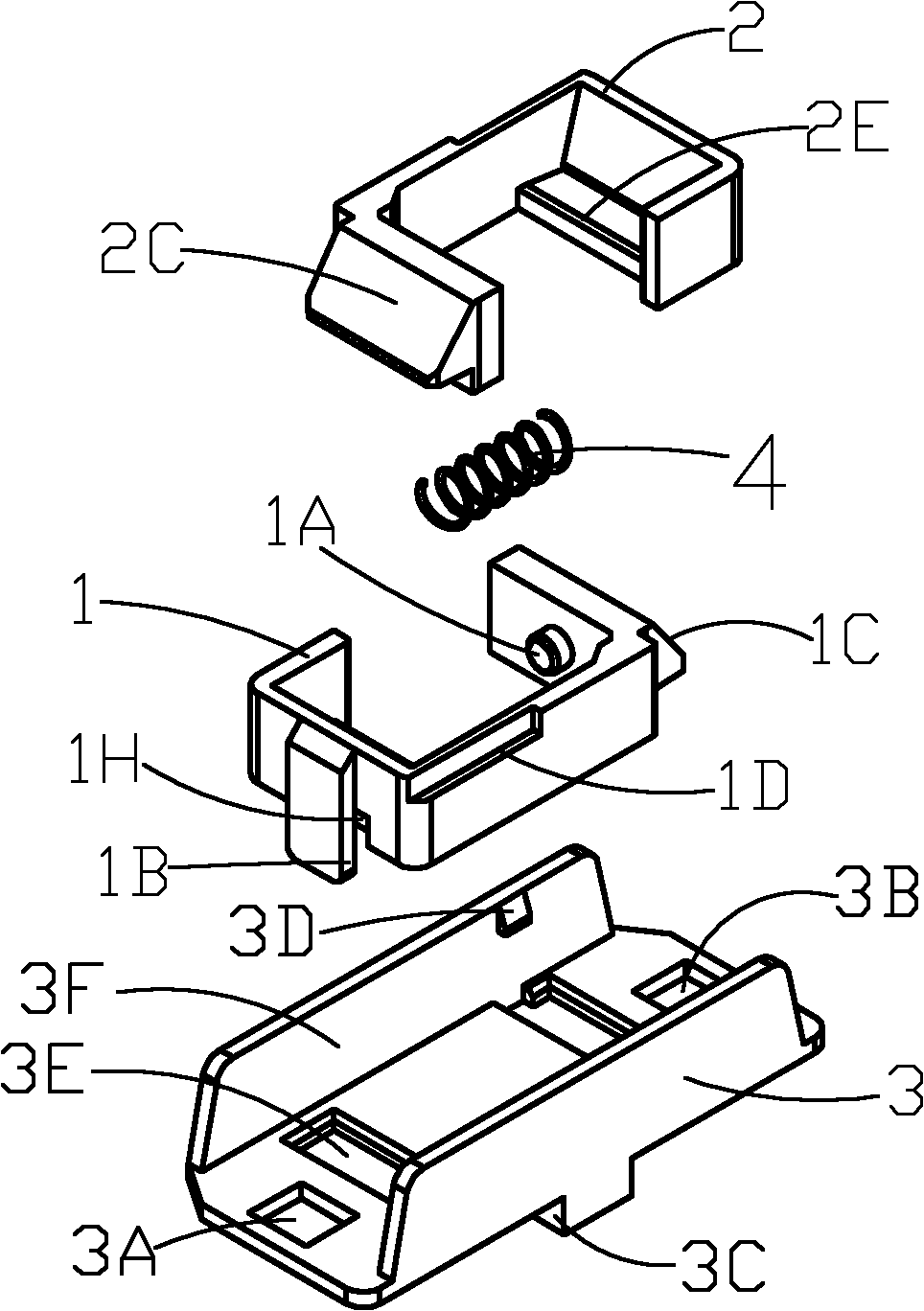

[0033] refer to Figure 1 to Figure 6 , this embodiment is aimed at the power socket whose left and right jacks are I-shaped holes, including a shell, conductive sockets (331, 321) and a power jack safety baffle device. In the figure, the leakage protection socket is taken as an example, the shell The body includes a loam cake 36 and a base (not shown in the figure), and the loam cake 36 has double I-shaped jacks (361, 362), and also includes a middle bracket 35, which has a baffle rail support arm 34 on the middle bracket, and a conductive socket They are respectively located on the two output conductors (32, 33), and the output conductors (32, 33) are installed on the side of the middle support. The safety baffle device of the power socket includes a left baffle 1, a right baffle 2 and a baffle guide rail 3, and the baffle guide rail 3 is provided with a guide hole 3E for exposing the conductive socket; the left and right baffles respectively include cross-fit frame and the...

Embodiment 2

[0040] refer to Figure 8 to Figure 1 4. This implementation is aimed at the leakage protection socket whose left jack is I-shaped and the right jack is T-shaped. The right guide jack 3B of the baffle guide rail is T-shaped, and the frames of the left and right baffles have upper and lower coincidence respectively. The step-shaped gap (1G, 2G); the frame of the right baffle is provided with a small baffle 5 that can move in a vertical direction relative to the movement track of the right baffle, and the baffle guide rail 3 has a gap for the movement of the small baffle. There is a guide rail 2L, and the small baffle 5 has a first guide groove 5A that cooperates with the right baffle guide rail 2L; the upper part of the small baffle 5 has a function of the T-shaped plug to make the small baffle retreat along the direction perpendicular to the movement track of the right baffle The front end of the left baffle block has a lock block 1X, and the left side of the small baffle 5 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com