Device for scanning the division mark of a mechanical roller-type counter, for any type of counter

A counting mechanism and counter technology, which is applied to counters with additional devices, electric devices, counting mechanisms/items, etc., can solve the problems of digital rollers with error reading, increased rotational friction, and sensitivity to magnetic effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

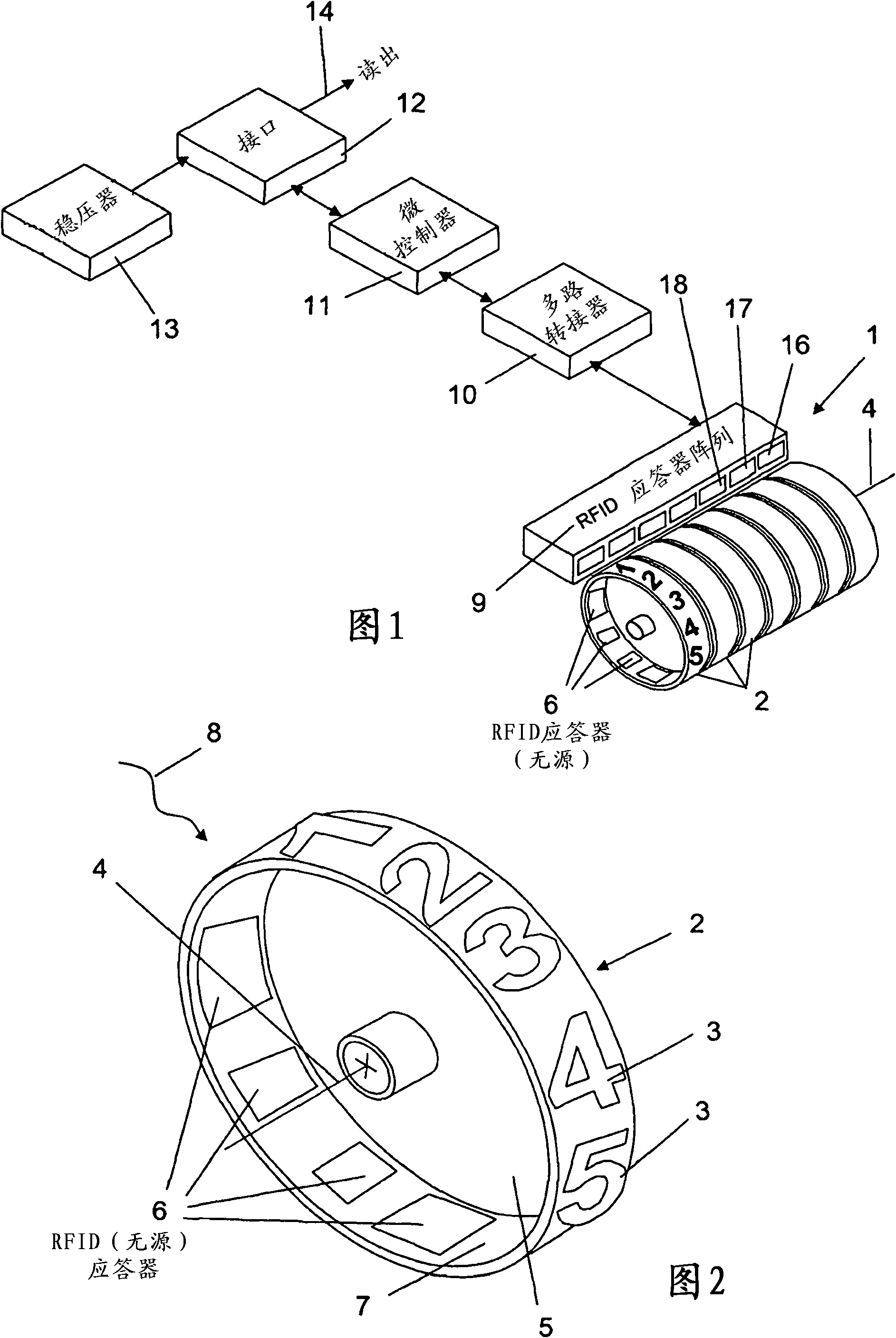

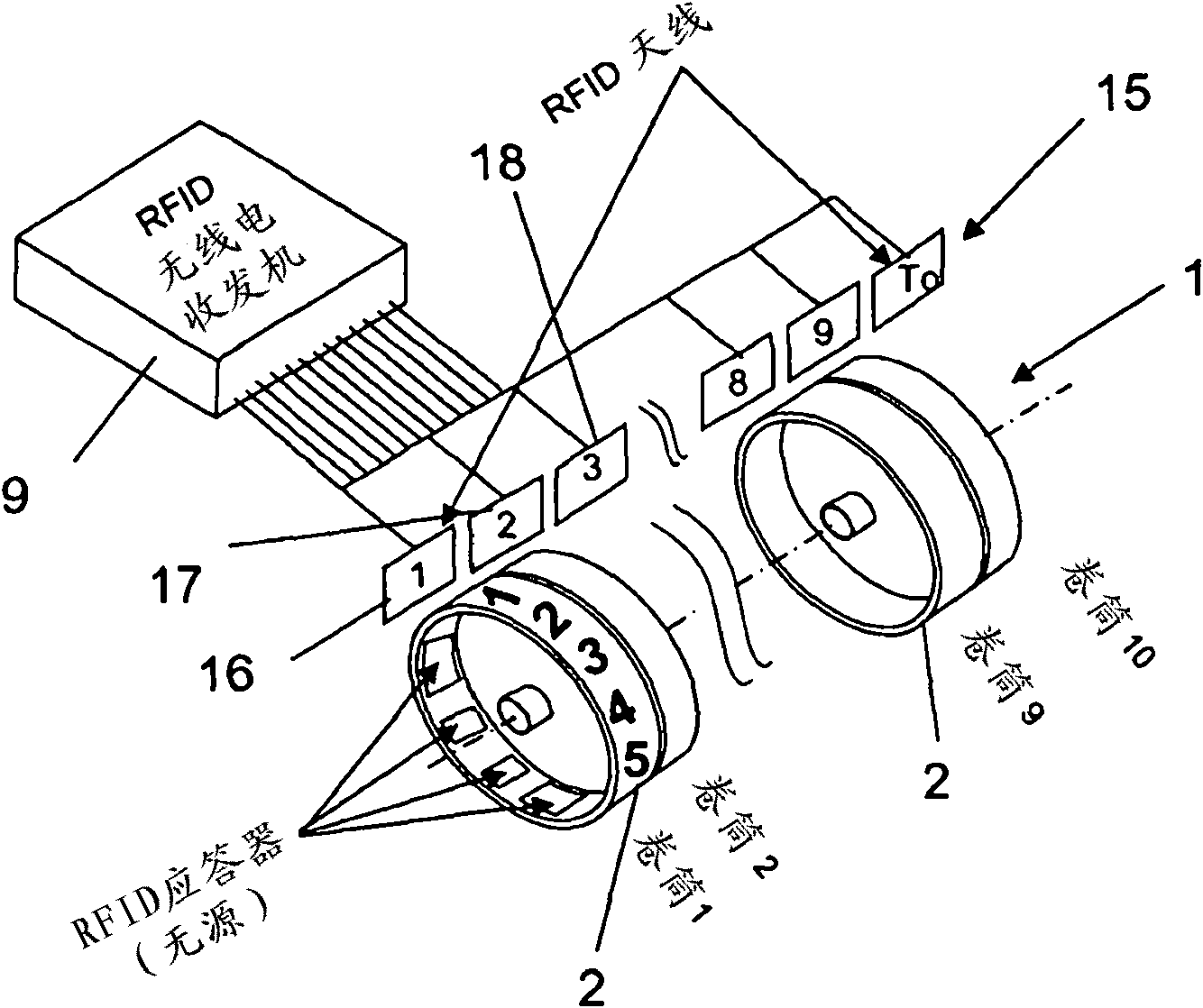

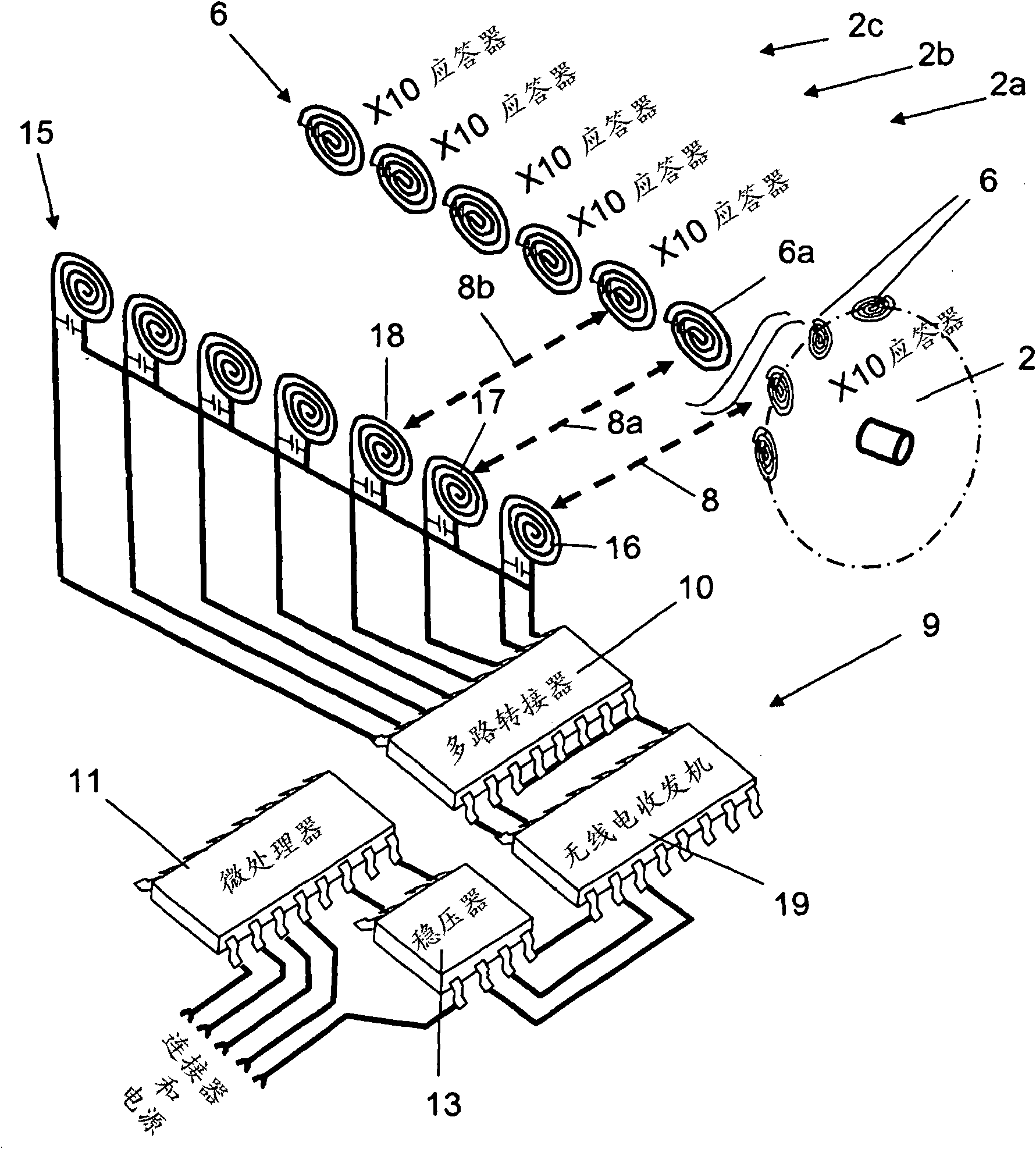

[0084] exist figure 1 and 3 shows generally a mechanical roller counting mechanism 1 comprising a plurality of numbered rollers 2 which are rotated on a common axis of rotation 4 by a step drive not shown in the figure be driven.

[0085] Such as image 3 As shown, each number roller 2 is provided with numbers 3 distributed on the circumference, and these numbers enable an optical / visual readout of the counting mechanism 1 .

[0086] The presence of the numeral 3 or the symbol is of course not necessary for a purely electronic reading of the counting mechanism. They can be omitted in this case.

[0087] Each number roller 2 is substantially designed as a cylindrical hollow body and forms an inner space 5 which is open at one end, so that an inner peripheral surface 7 emerges from the inner space.

[0088] According to the present invention, a plurality of transponders 6 are arranged according to a certain interval. figure 2 It is arranged on the inner side of the periph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com