Warmer of wet-process extracting groove and warming method

An extraction tank and warmer technology, applied in the field of wet extraction tank heaters, can solve the problems of low ambient temperature of the extraction tank, affecting the quality of the separated product, poor extraction and separation effect, etc. High, low production and operating costs, ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

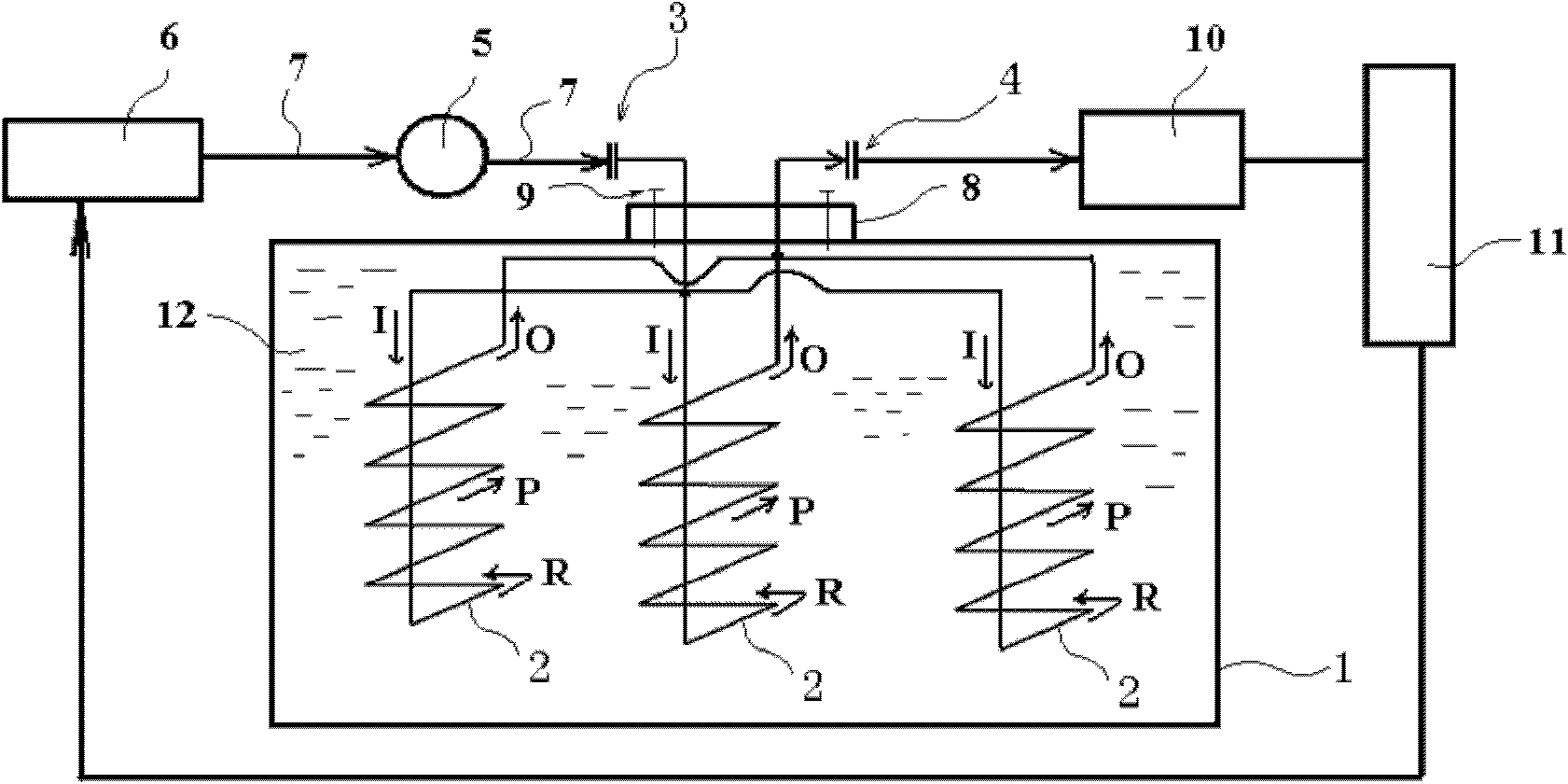

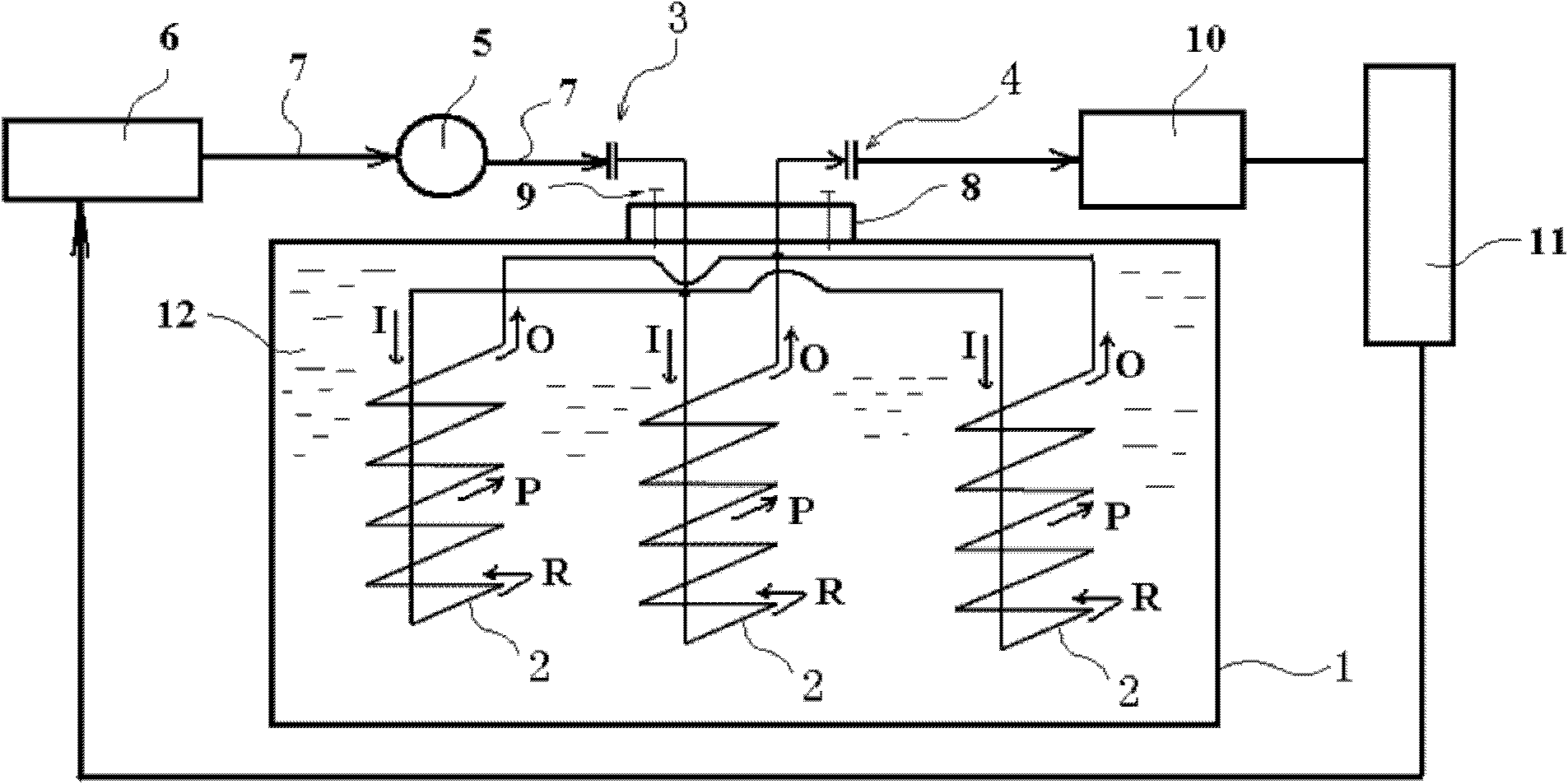

[0018] Such as figure 1 As shown, an extraction tank heater according to the present invention includes a heating tube 2; the heating tube 2 is a serpentine coiled glass tube, and the two ends of the heating tube 2 are respectively provided with an air inlet 3 and an outlet. The air hole 4 and the air inlet 3 are connected to the steam supply device 6 through the steam pipe 7, and the steam pipe 7 is provided with a pressure regulating valve 5, which is used to adjust the steam pressure entering the heating pipe 2; the hot steam passes through the air inlet at one end 3 After entering the heating tube 2, it is discharged in liquid form from the air outlet 4 at the other end.

[0019] In another embodiment, hot water or micro steam is discharged from the air outlet 4 at the other end, and the hot water or micro steam is accommodated in a device 10 capable of accommodating hot water or micro steam. In another embodiment, the device 10 capable of containing hot water or micro st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com