Device for monitoring a fixed leafspring clamped on one side in a machine for producing tobacco products

A technology for tobacco products and leaf springs, which is applied in the field of leaf spring devices, can solve the problems of expensive leaf springs, cannot use leaf springs, and no signal is sent, and achieves the effect of simplifying installation and structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

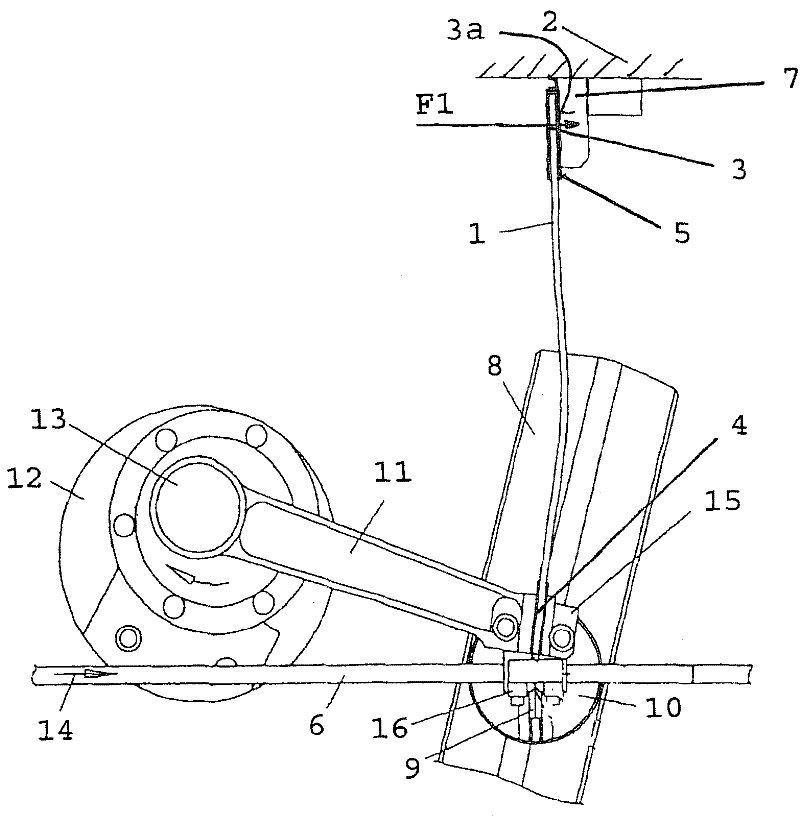

[0016] exist figure 1 A partial view of a machine used to produce tobacco products, such as cigarettes, can be seen in . The cutting device of the machine is shown in said partial view. In the cutting device, the rod 6 fed in the feed direction 14 is cut into cigarettes of defined length. The cutting device comprises a rotating knife holder 8 . The tool holder has a cardan-shaped tool receptacle 10 in it. The tool 9 is fixed and tensioned in the tool receptacle. Furthermore, the rotary drive 12 is provided with an eccentric rotary bearing 13 . The connecting rod 11 is rotatably mounted on said rotary bearing. When the driving device 12 rotates, the connecting rod 11 is driven to perform repeated reciprocating swinging motions by being supported on the eccentric rotating bearing 13 . Furthermore, a leaf spring 1 is provided. The leaf spring is fixed with a first end 3 to a support 2 fixed to the machine and is connected with a second end 4 to the end 15 of the connecting...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap