Arc extinguishing equipment of moulded case circuit breaker

A technology of molded case circuit breaker and arc extinguishing device, which is applied in the direction of circuit breaker components, etc., can solve the problems of air blowing pressure drop in the arc extinguishing chamber, grid short-circuiting, insufficient air blowing pressure strength, etc., and achieve enhanced current limiting performance , Improve the effect of breaking and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

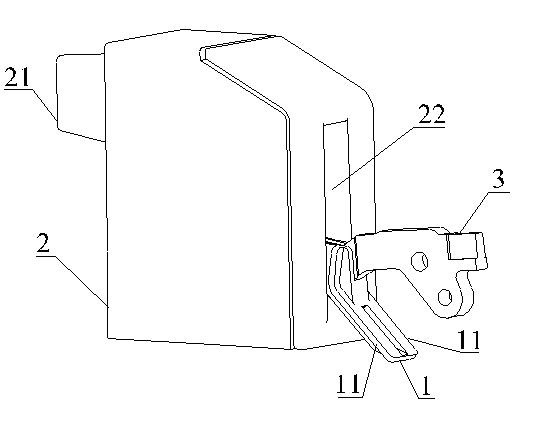

[0017] see image 3 and Figure 4 , the present invention has an arc extinguishing chamber 2, the arc extinguishing chamber 2 is a cavity structure, an air outlet 21 is arranged on the front wall of the arc extinguishing chamber 2, and a rear opening 22 is opened on the rear wall of the arc extinguishing chamber 2, so as to Make way for the action of moving contact 3. The front end of the moving contact 3 extends into the inner cavity of the arc extinguishing chamber 2 from the outside through the rear opening 22 , and the moving contact 3 moves up and down along the rear opening 22 during the opening and closing process of the circuit breaker.

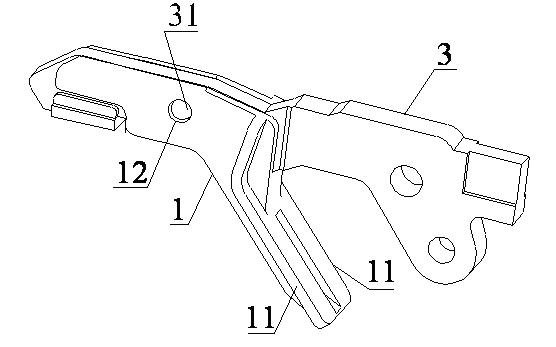

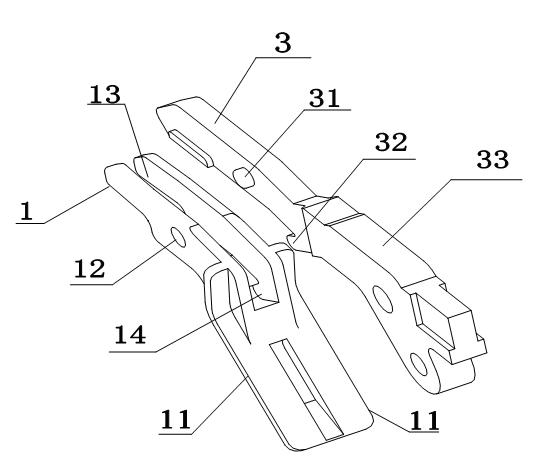

[0018] see figure 1 and 2 As shown, the present invention connects a movable contact plastic part 1 at the front end of the movable contact 3, and the movable contact plastic part 1 is divided into front and rear parts, and the front part is used for fixedly connecting the movable contact 3. The front part has a groove 13, and rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com