Print head, printer

A technology of printing head and stage, applied in printing, inking device, device for coating liquid on the surface, etc., can solve the problem that residual vibration cannot be completely eliminated and residual vibration is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

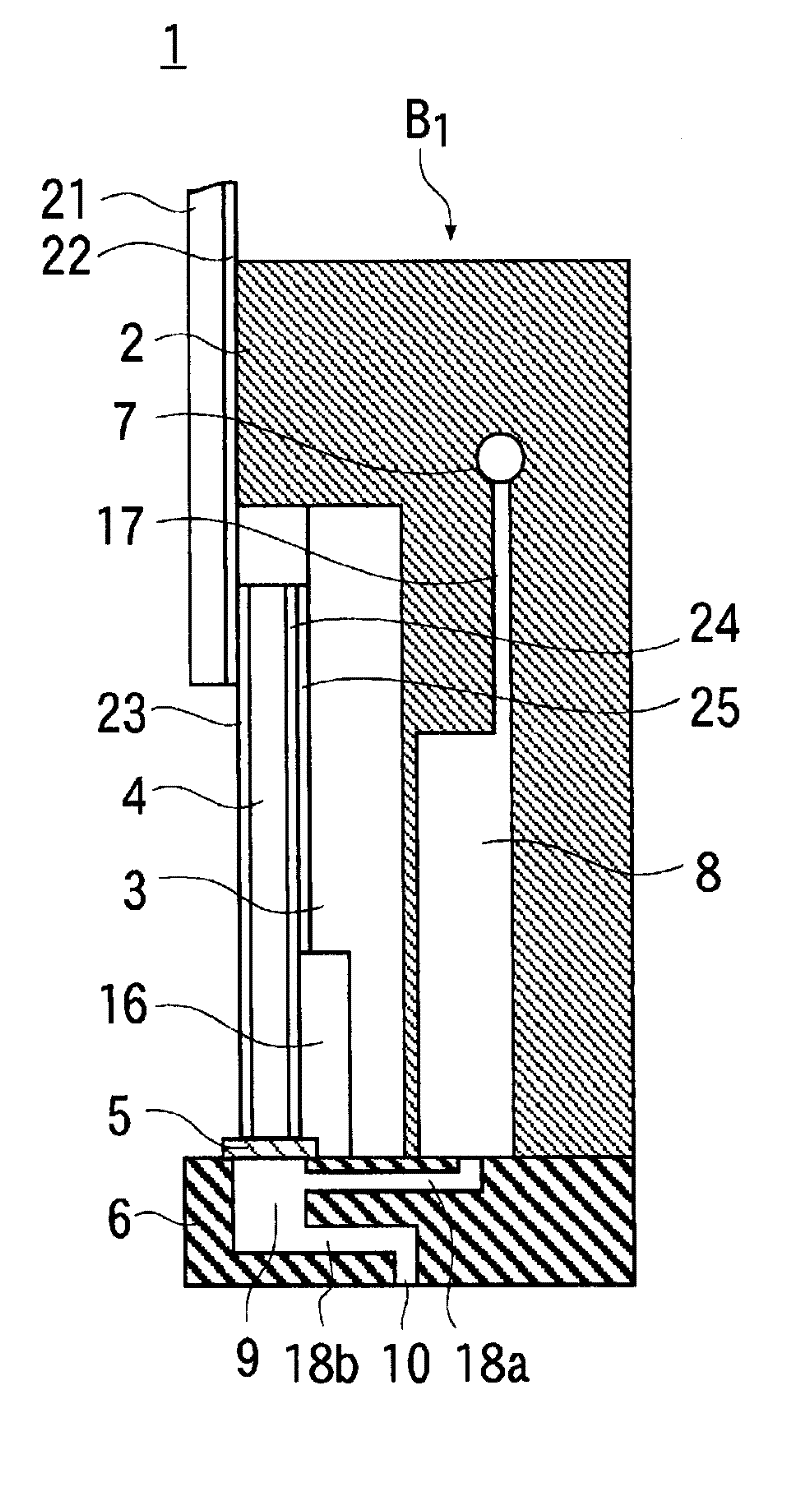

[0038] figure 1 Reference numeral 50 is an example of a printing device of the present invention.

[0039] This printing apparatus 50 has a base 51 on which a substrate mounting table 53 is arranged via a mounting table moving device 52 . A device for moving the substrate mounting table 53 is provided on the mounting table moving device 52 , and the substrate mounting table 53 can reciprocate on the base 51 .

[0040] A bridge 54 is arranged at a position above the moving range of the substrate stage 53 . A head moving device 56 is provided on the bridge 54 , and the printing head 1 is movably attached to the head moving device 56 . A device for moving the print head 1 is provided on the head moving device 56 , and the print head 1 can reciprocate in a direction perpendicular to the reciprocating direction of the substrate stage 53 at a position above the substrate stage 53 .

[0041] The printing device 50 is provided with a discharge liquid tank 57 that stores the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com