Print head, printer

A technology of printing head and mounting table, which is applied in printing, inking device, lighting device, etc., and can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

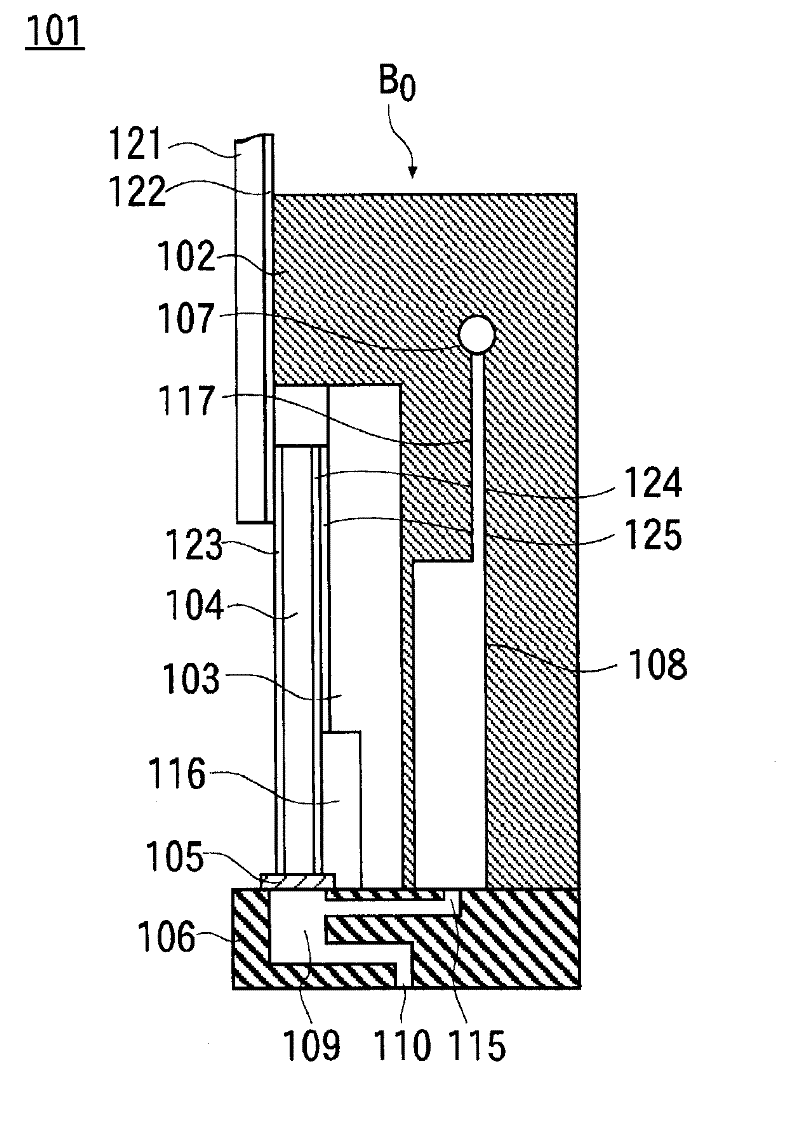

[0045] figure 1 Reference numeral 50 is an example of a printing device of the present invention.

[0046] This printing apparatus 50 has a base 51 on which a substrate mounting table 53 is arranged via a mounting table moving device 52 . A device for moving the substrate mounting table 53 is provided on the mounting table moving device 52 , and the substrate mounting table 53 can reciprocate on the base 51 .

[0047] A bridge 54 is arranged at a position above the moving range of the substrate stage 53 . A head moving device 56 is provided on the bridge 54 , and the printing head 1 is movably attached to the head moving device 56 . A device for moving the print head 1 is provided on the head moving device 56 , and the print head 1 can reciprocate in a direction perpendicular to the reciprocation direction of the substrate stage 53 at a position above the substrate stage 53 .

[0048] The printing device 50 is provided with a discharge liquid tank 57 that stores the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com