inkjet ink

A kind of ink and inkjet technology, which is applied in the direction of ink, application, household utensils, etc., can solve the problems of ink gelation, ink is not easy, etc., and achieve excellent solvent resistance, excellent cleaning resistance, and good solvent resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

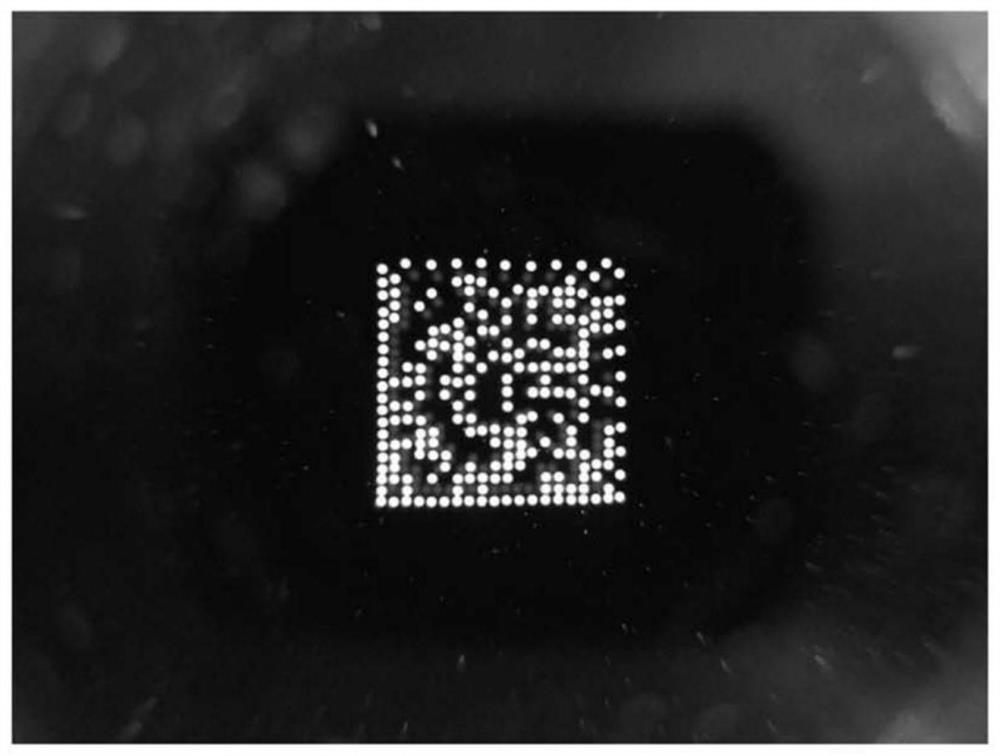

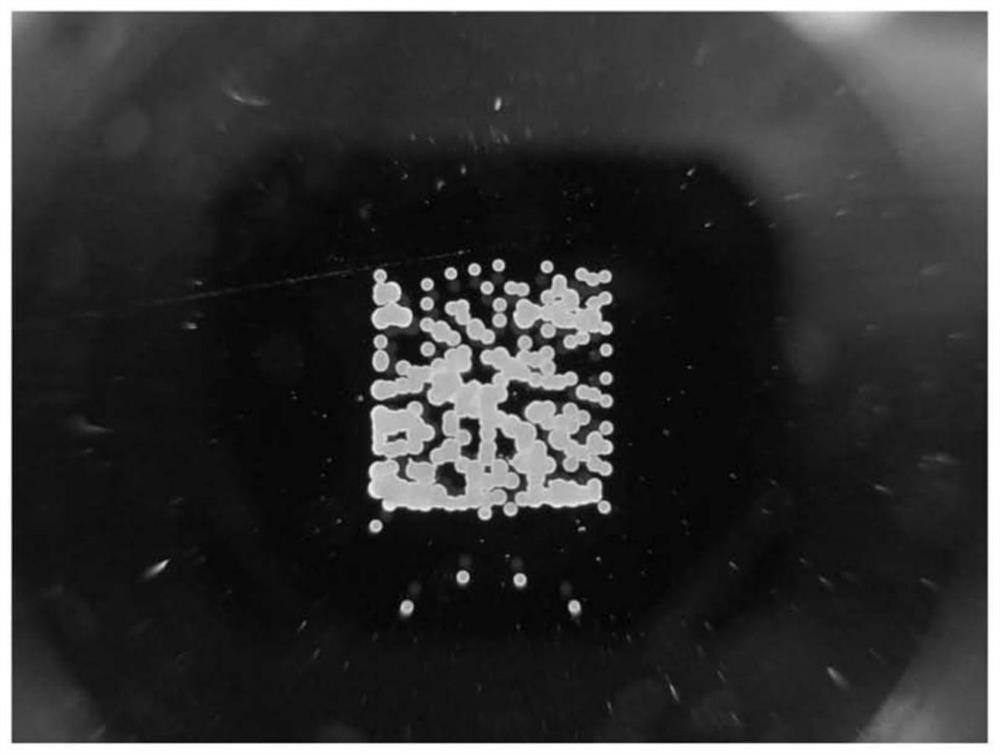

Image

Examples

Embodiment 1

[0089] 15 parts by weight of poly-p-vinylphenol resin (weight average molecular weight Mw=11000) and 3 parts by weight of Solsperse 38500 (dispersant: manufactured by Lubrizol Corporation) were dissolved in 58.5 parts by weight of methyl ethyl ketone and 5 parts by weight of cyclopentanone Parts, make a solution, add titanium oxide (Al·Si treatment, rutile TiO 2 , average particle diameter of 0.24 μm) 10 parts by weight, stirred and mixed, and the mixed solution was supplied to a horizontal sand mill to disperse titanium oxide.

[0090] To this dispersion liquid, 7 parts by weight of blocked isocyanate using dimethylpyrazole as a blocking agent was added and mixed, and 1.5 parts by weight of tetrabutylammonium hexafluorophosphate was further added and mixed with high-speed stirring.

[0091] Then, the mixed dispersion liquid was filtered through a filter with a mesh size of 1.0 μm to obtain an ink for an inkjet printer.

[0092] It should be noted that in the trial production...

Embodiment 2~10、 comparative example 1、2

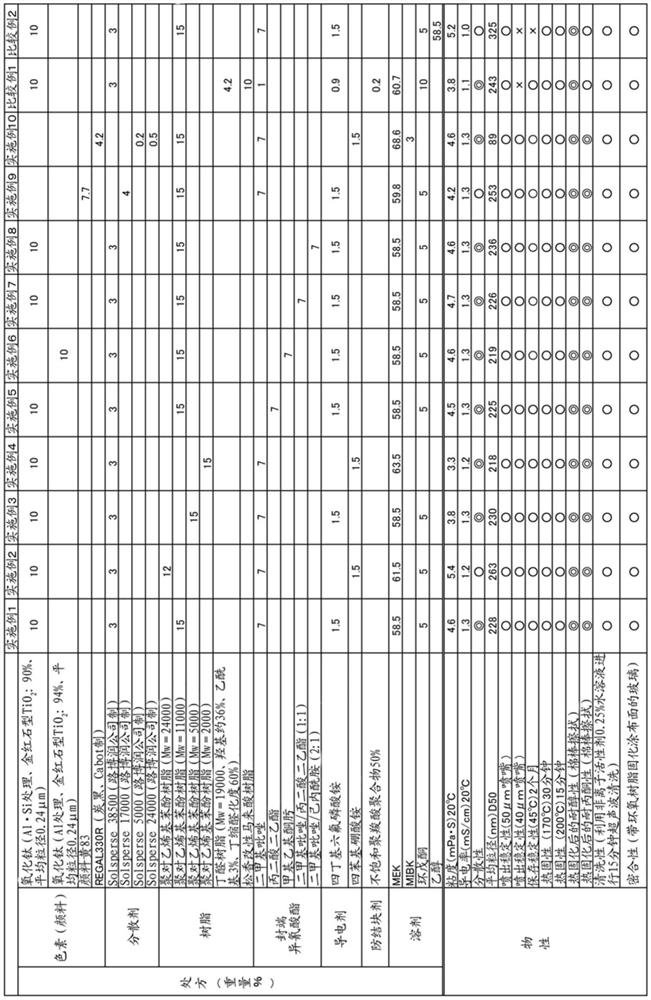

[0094] Each ink of Examples 2-10 and Comparative Examples 1 and 2 was prepared in the same manner as in Example 1 except that various raw materials were changed as shown in Table 1 below. In Table 1, the prescription of Example 1 is also described together.

[0095] It should be noted that in Table 1, the numerical values given in the prescription column all represent weight % relative to the total weight of the ink.

[0096] Table 1

[0097]

[0098] 〔Physical property evaluation of ink〕

[0099] The physical properties of the ink were evaluated and described in Table 1 above.

[0100] The details of the evaluation items are as follows.

[0101]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com