Non-aqueous pigment ink

A non-aqueous, non-aqueous resin technology, applied in the direction of ink, copy/marking method, application, etc., can solve the problems of easy occurrence of print-through, lower printing density, etc., to reduce print-through, improve storage stability, and improve spray the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

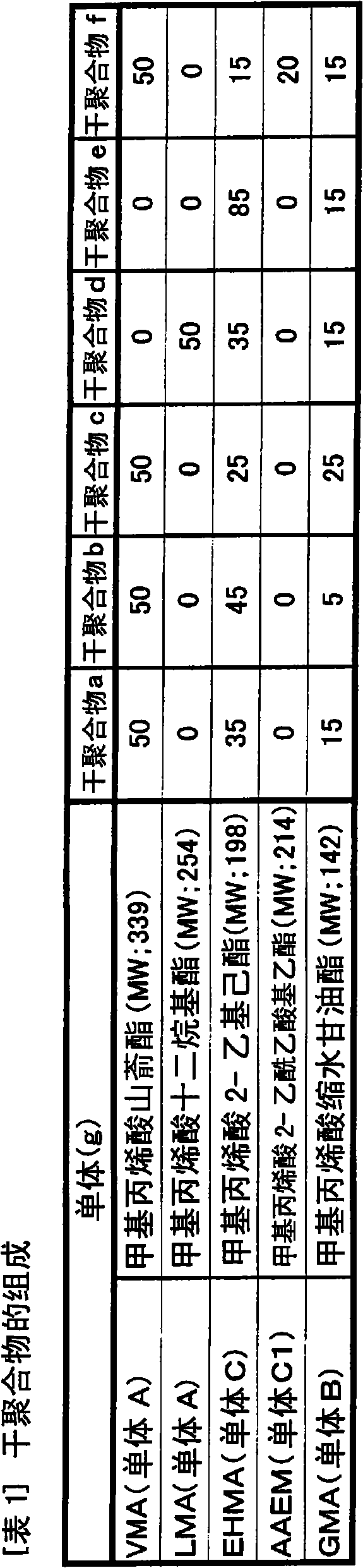

[0093] (1) Synthesis of copolymers (dry polymers a to f)

[0094] 75 g of AF-4 (a naphthene-based solvent; manufactured by Nippon Oil Corporation) was placed in a 300 ml four-neck flask, and the temperature was raised to 110° C. while blowing nitrogen gas and stirring. Then, the temperature was kept at 110° C., and 16.7 g of AF-4, 2 g of Perbutyl O (2-ethyl tert-butyl peroxyhexanoate; Japan Co., Ltd.) mixture. Then, the temperature was kept at 110° C., and 0.2 g of Perbutyl O were added after 1 hour and 2 hours each. Furthermore, aging was carried out at 110° C. for 1 hour and diluted with 10.6 g of AF-4 to obtain colorless and transparent dry polymer a to f solutions with a non-volatile content of 50%.

[0095] The mass average molecular weight (GPC method, standard polystyrene conversion) of each obtained dry polymer was 20,000 to 23,000.

[0096] [Table 1]

[0097]

[0098] Details of the monomers used are shown below.

[0099] Monomer (A): VMA (the carbon number of...

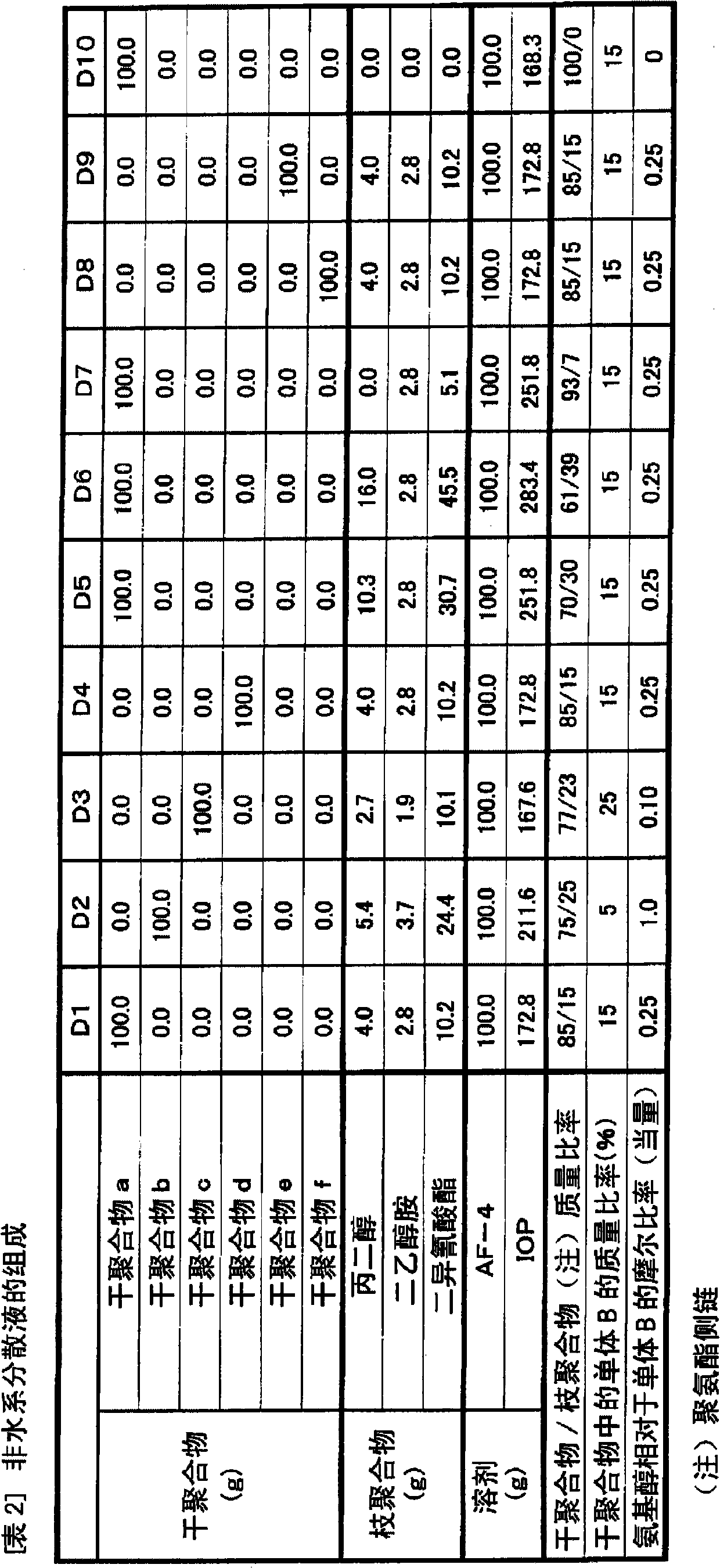

Embodiment 2~8、 comparative example 1~4

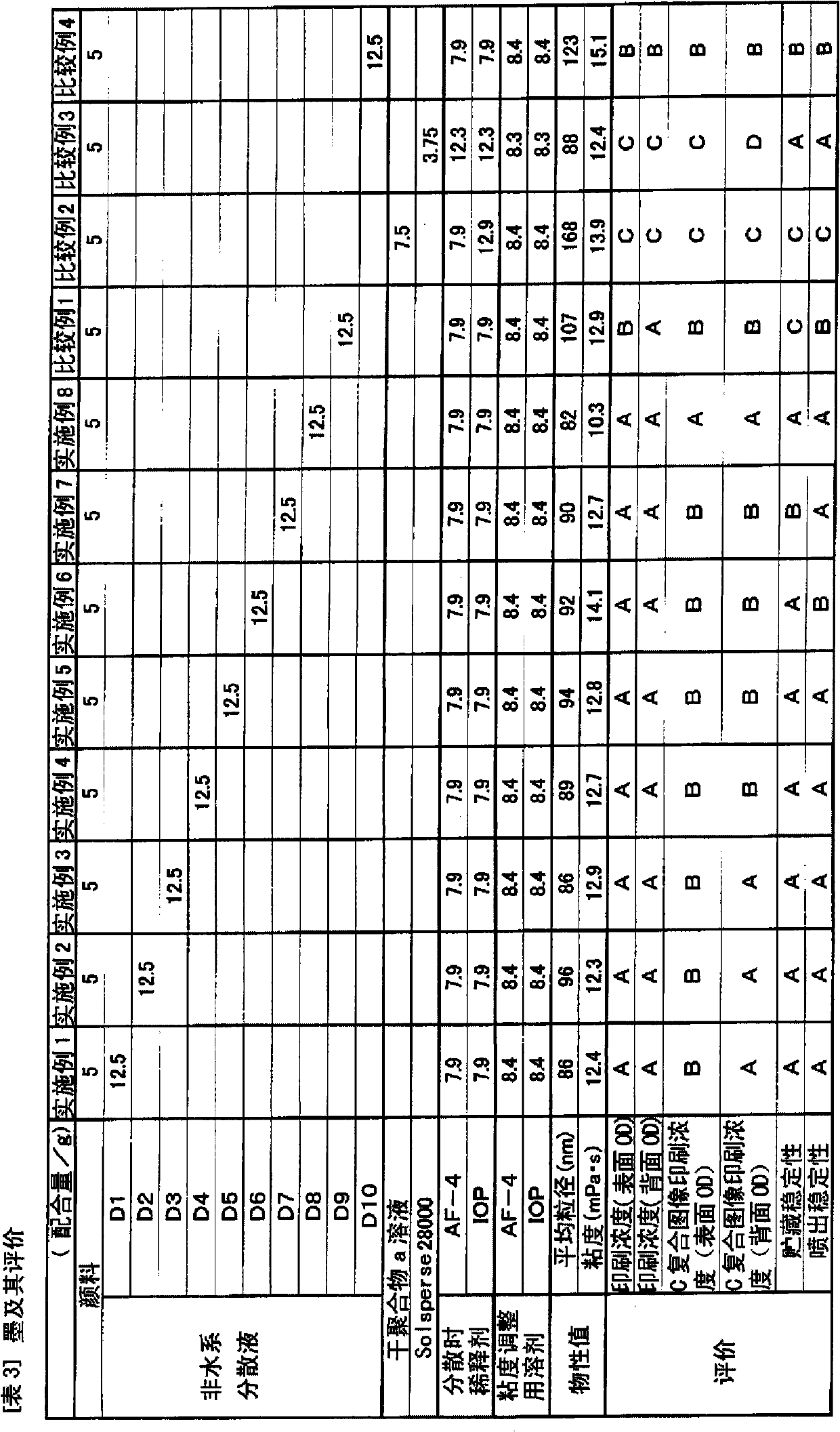

[0127] According to the formulation shown in Table 3, the inks of the respective examples and comparative examples were obtained in the same manner as in Example 1 above.

[0128] In Comparative Examples 2 and 3, a dry polymer a solution (50% solid content) and Solsperse 28000 (manufactured by The Lubrizol Corporation, 100% solid content) were used instead of the non-aqueous dispersion liquid, respectively.

[0129] [table 3]

[0130]

[0131] All of the obtained inks had a viscosity and a pigment particle diameter within an appropriate range for inkjet inks. The particle size of the ink was measured with a dynamic light scattering particle size distribution device LB-500 manufactured by Horiba Seisakusho. The viscosity of the ink is the viscosity when the shear stress is increased from 0 Pa to 10 Pa at a rate of 0.1 Pa / s at 23°C. The stress-controlled rheometer RS75 (cone angle 1°, diameter 60mm) manufactured by HAAKE Co., Ltd. To measure.

[0132]

[0133] Each ink w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com