a kind of gr-sio 2 /ci material preparation method and atomization gel forming device

A gr-sio2, chloroprene latex technology, applied in the field of rubber mixing, can solve the problems of re-agglomeration of fillers, decreased wear resistance, poor compatibility, etc., and achieves low production cost, low rolling resistance, simple and acceptable process. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

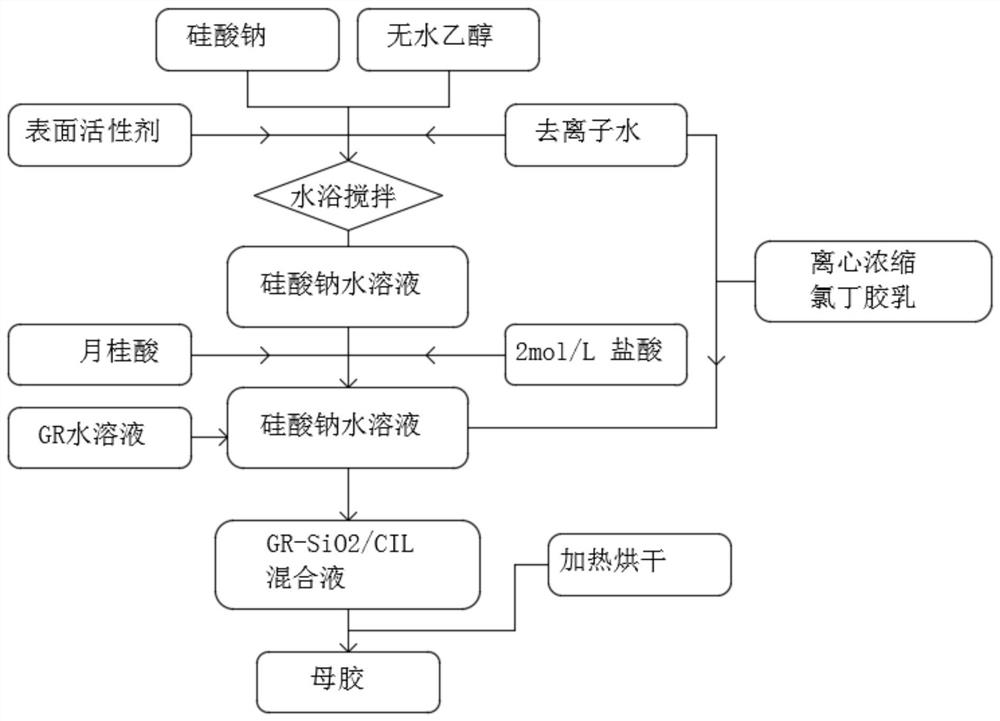

[0043] Such as figure 1 As shown, the present invention provides a GR-SiO 2 / CI composite material preparation method, comprises the steps:

[0044] S100, mix sodium silicate, deionized water, absolute ethanol and surfactant in proportion, and stir under heating in a water bath at 70-75°C to form a modified sodium silicate aqueous solution;

[0045] S200, adding an appropriate amount of lauric acid and 2mol / L hydrochloric acid to the modified sodium silicate aqueous solution, and filtering after fully reacting to obtain a modified silicon dioxide solid-liquid mixture;

[0046] S300. Put the modified silicon dioxide solid-liquid mixture in a beaker, add an appropriate amount of deionized water to 30 parts by mass, and add 3 parts by mass of GR aqueous solution after high-speed stirring to form GR-SiO 2 Mixed solution, 100 parts by mass of dry glue with a mass fraction of 60wt% centrifugally concentrated neoprene latex added to GR-SiO 2 In the mixed solution, GR-SiO 2 / CIL m...

Embodiment 2

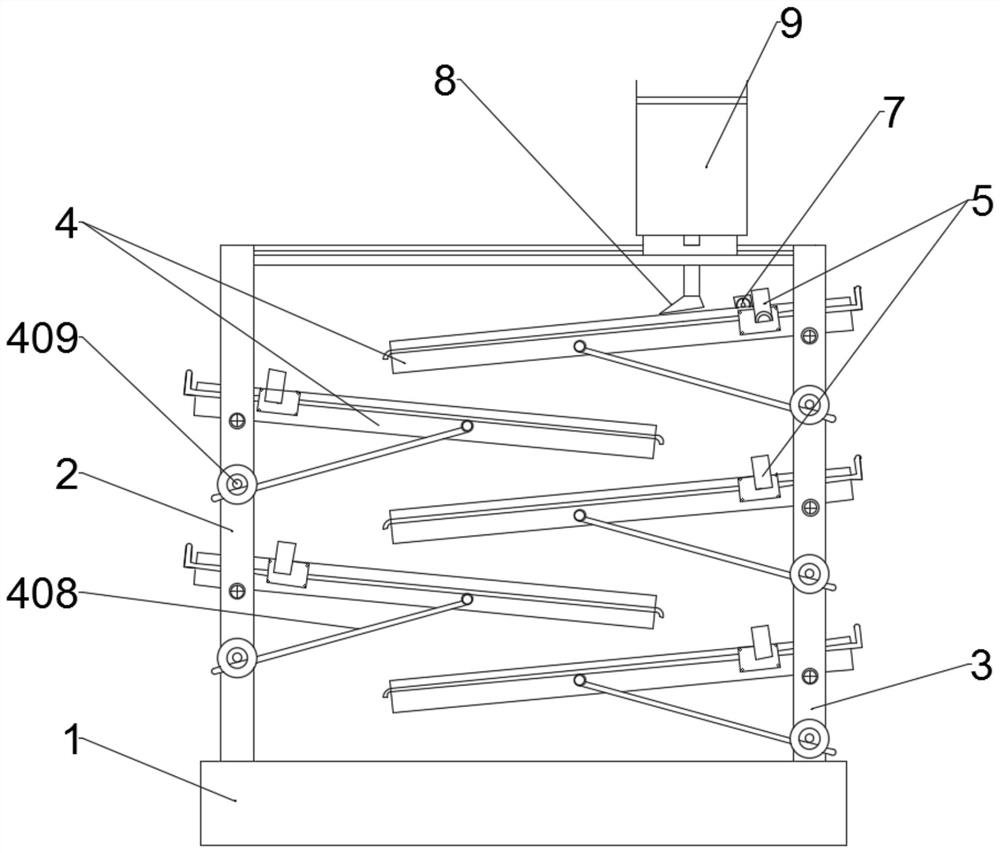

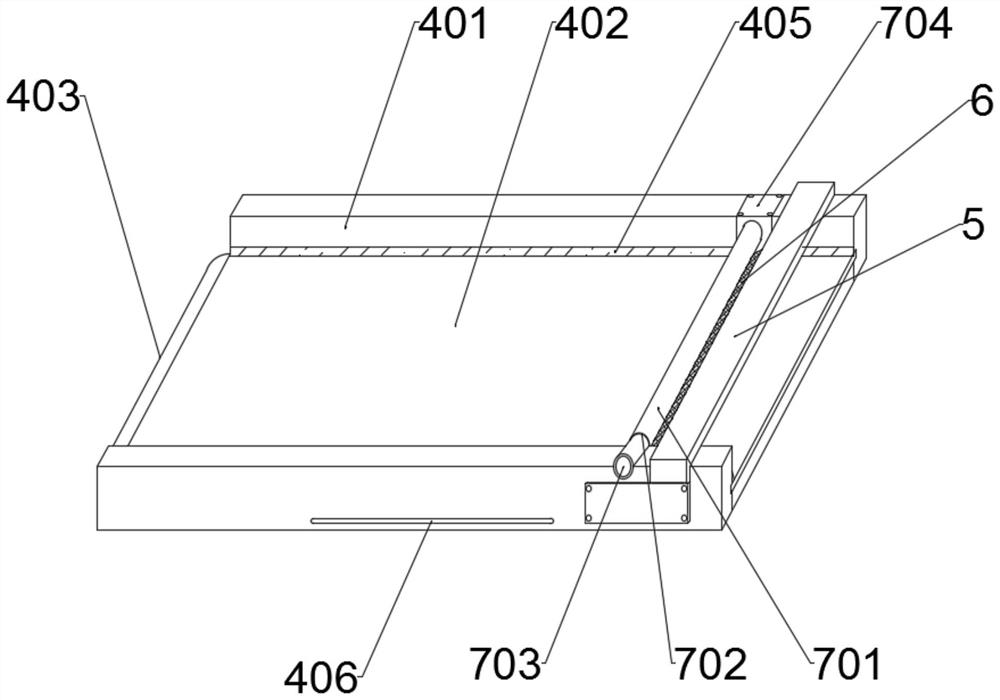

[0059] Such as Figure 2 to Figure 5 Shown, the present invention also provides a kind of GR-SiO used in embodiment 1 2 Atomization and glue forming device of / CI composite material, including a base 1 and a left support frame 2 and a right support frame 3 installed on the base 1, and several glue drying devices 4 are arranged at equal intervals on the left support frame 2 and the right support frame 3 , and several rubber drying devices 4 on the left support frame 2 and the right support frame 3 are arranged to cross each other, the top of the rubber drying device 4 is provided with a squeegee knife holder 5, and the squeegee knife holder 5 is provided with an arc-shaped cross section. The scraper 6 is provided with a glue equalizing device 7 on the glue drying device 4 at the top of the right support frame 3, and a cloth glue seat 8 is arranged on the right support frame 3 outside the glue equalizing device 7, and a rubber cloth seat 8 is installed in the middle of the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com