Non-aqueous pigment ink

A non-aqueous, non-aqueous resin technology, applied in the direction of ink, copying/marking methods, applications, etc., can solve the problems of easy occurrence of print through, low printing density, etc., achieve reduction of print through, improve storage stability, improve spray the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

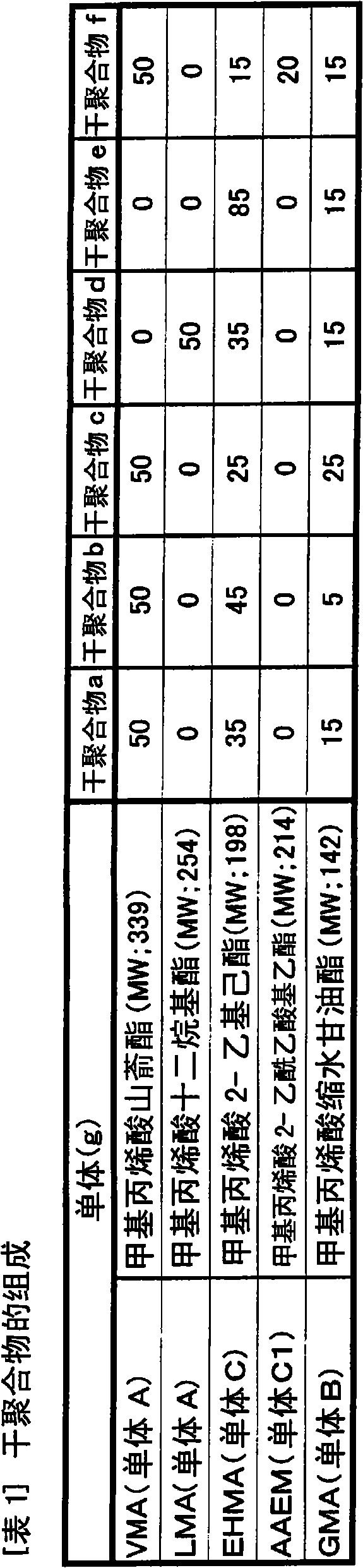

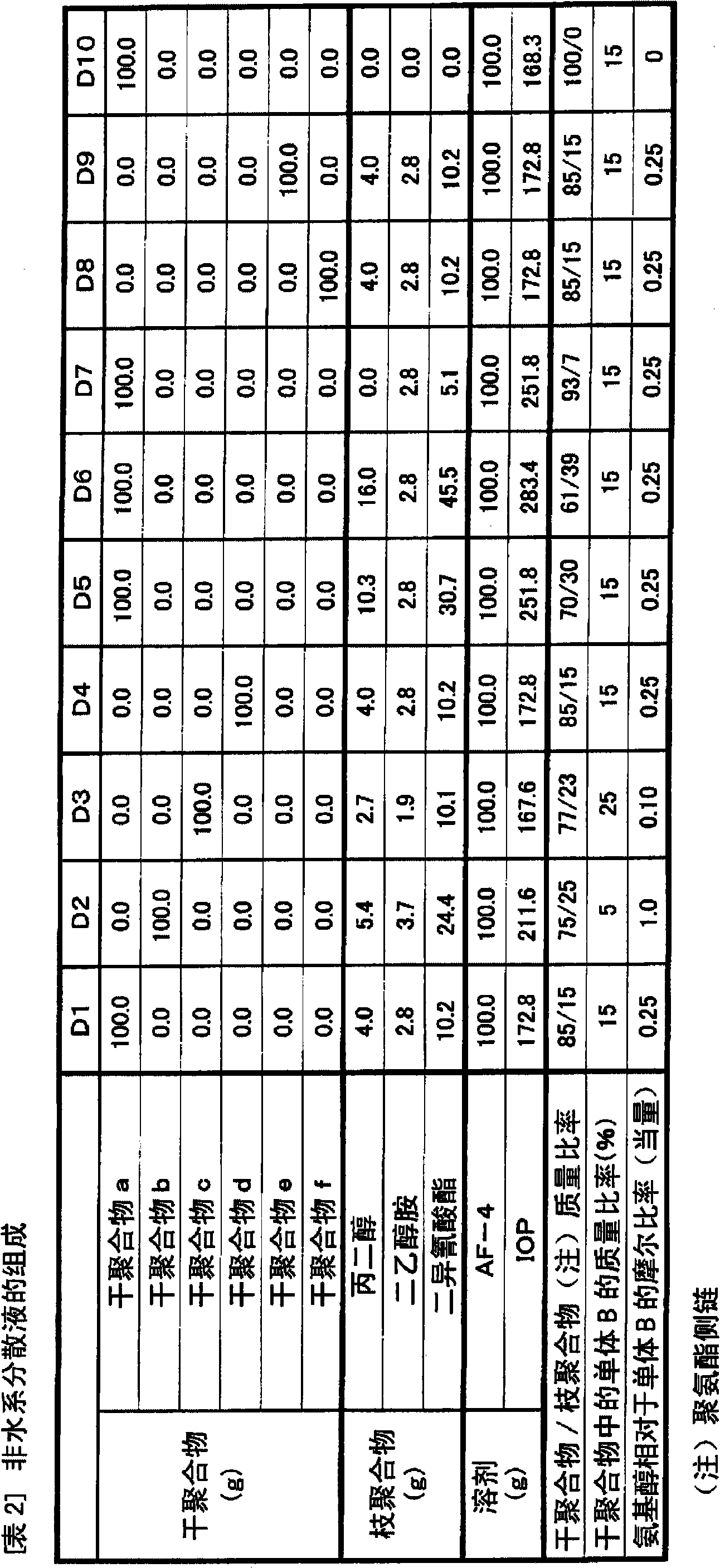

[0093] (1) Synthesis of copolymers (dry polymers a to f)

[0094] 75 g of AF-4 (a naphthene-based solvent; manufactured by Nippon Oil Corporation) was placed in a 300 ml four-neck flask, and the temperature was raised to 110° C. while blowing nitrogen gas and stirring. Then, the temperature was kept at 110° C., and 16.7 g of AF-4, 2 g of Perbutyl O (2-ethyl tert-butyl peroxyhexanoate; Japan Co., Ltd.) mixture. Then, the temperature was kept at 110° C., and 0.2 g of Perbutyl O were added after 1 hour and 2 hours each. Furthermore, aging was carried out at 110° C. for 1 hour and diluted with 10.6 g of AF-4 to obtain colorless and transparent dry polymer a to f solutions with a non-volatile content of 50%.

[0095] The mass average molecular weight (GPC method, standard polystyrene conversion) of each obtained dry polymer was 20,000 to 23,000.

[0096] [Table 1]

[0097]

[0098] Details of the monomers used are shown below.

[0099] Monomer (A): VMA (the carbon number o...

Embodiment 2~8、 comparative example 1~4

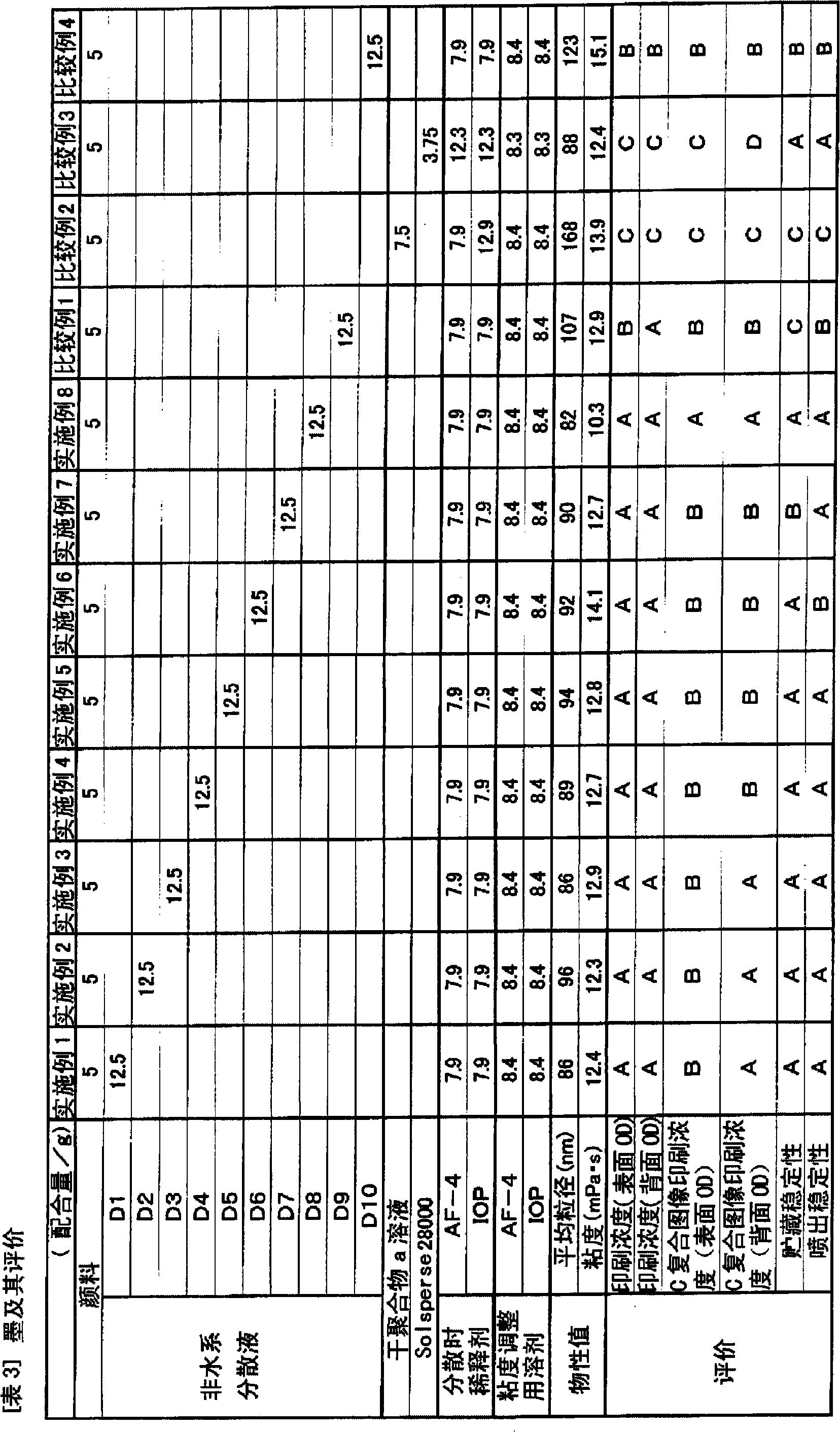

[0128] According to the formulation shown in Table 3, the inks of the respective examples and comparative examples were obtained in the same manner as in Example 1 above.

[0129] In Comparative Examples 2 and 3, a dry polymer a solution (50% solid content) and Solsperse 28000 (manufactured by The Lubrizol Corporation, 100% solid content) were used instead of the non-aqueous dispersion liquid, respectively.

[0130] [table 3]

[0131]

[0132] All of the obtained inks had a viscosity and a pigment particle diameter within an appropriate range for inkjet inks. The particle size of the ink was measured with a dynamic light scattering particle size distribution device LB-500 manufactured by Horiba Seisakusho. The viscosity of the ink is the viscosity when the shear stress is increased from 0 Pa to 10 Pa at a rate of 0.1 Pa / s at 23°C. The stress-controlled rheometer RS75 (cone angle 1°, diameter 60mm) manufactured by HAAKE Co., Ltd. To measure.

[0133]

[0134] Each ink ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com