Cleaning device for liquid material ejection device and method for controlling roll rotation performed in the cleaning device

A technology for cleaning devices and liquid materials, which is applied to devices that apply liquid to surfaces, coatings, printing, etc. High reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

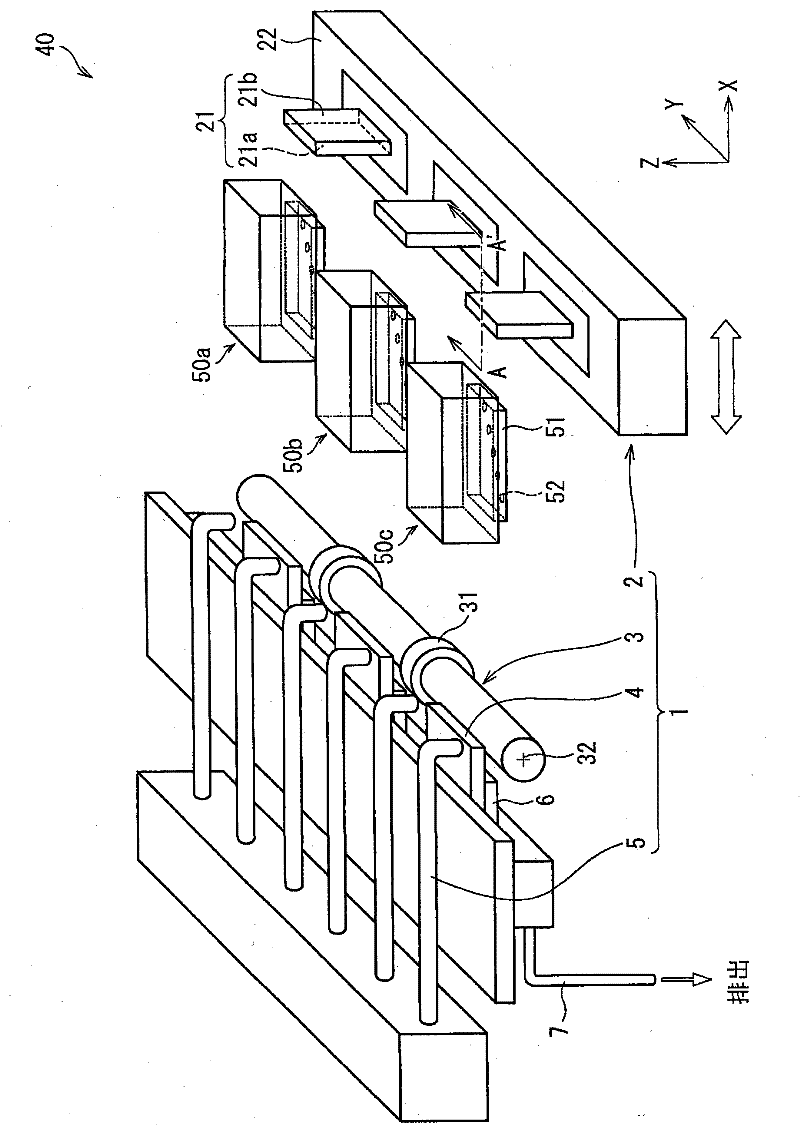

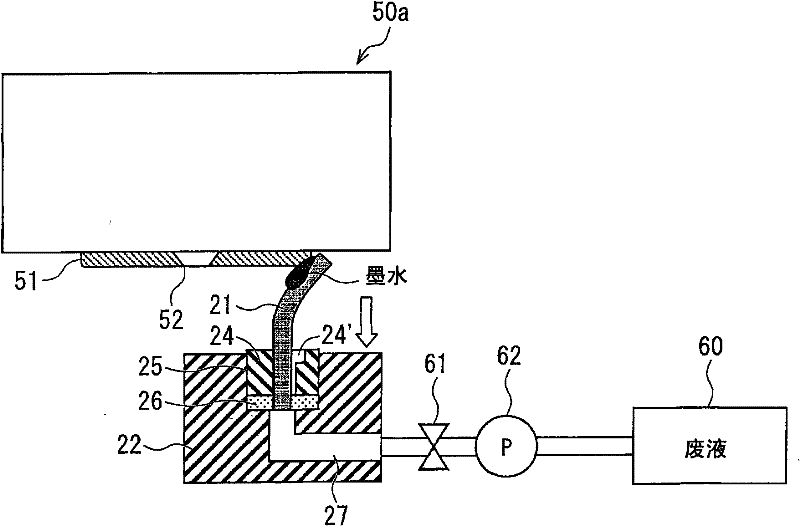

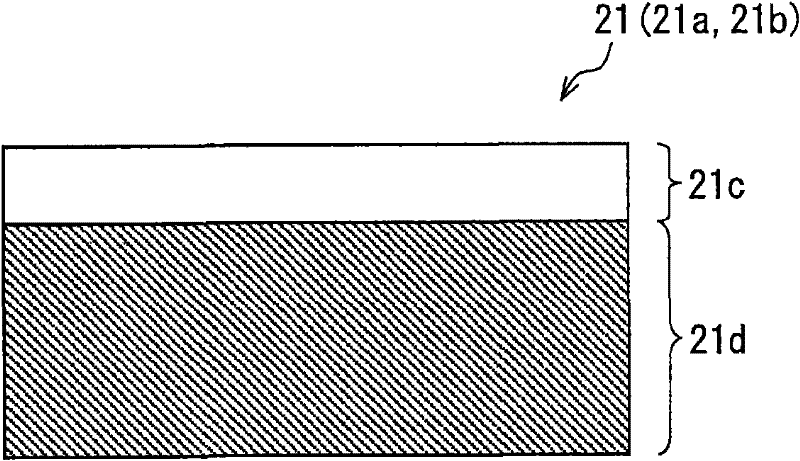

[0104] according to Figure 1 to Figure 12 One embodiment of the present invention will be described. In addition, in the following description, in order to implement the present invention, various limitations that are technically desirable are added, but the scope of the present invention is not limited to the following embodiments and drawings.

[0105] figure 1 It is a figure which shows the structure of the inkjet type liquid material discharge apparatus (hereinafter referred to as a liquid material discharge apparatus) of this embodiment. The liquid material ejection device 40 in the present embodiment can be for example red (R), blue (B), the ink of green (G) three primary colors is ejected to a material to be ejected to manufacture by R, B, G. It is used when the color filter (color filter) composed of three kinds of filters (filter) is used. Therefore, in this embodiment, a liquid material ejection device that ejects three kinds of R, B, and G inks will be describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com