Installation method of blades of offshore wind turbine

A blade installation and installation method technology, which is applied to wind turbines, wind turbine components, engines, etc., can solve problems such as difficult hoisting at high altitudes, high center of gravity of transported objects, and difficulty in controlling the installation angle, achieving convenient operation and low implementation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention is suitable for separate installation of offshore wind turbines. After the offshore wind turbine tower is installed, the installation method of the invention can be used to install the engine room and blades to the top of the wind turbine tower.

[0030] The specific steps are:

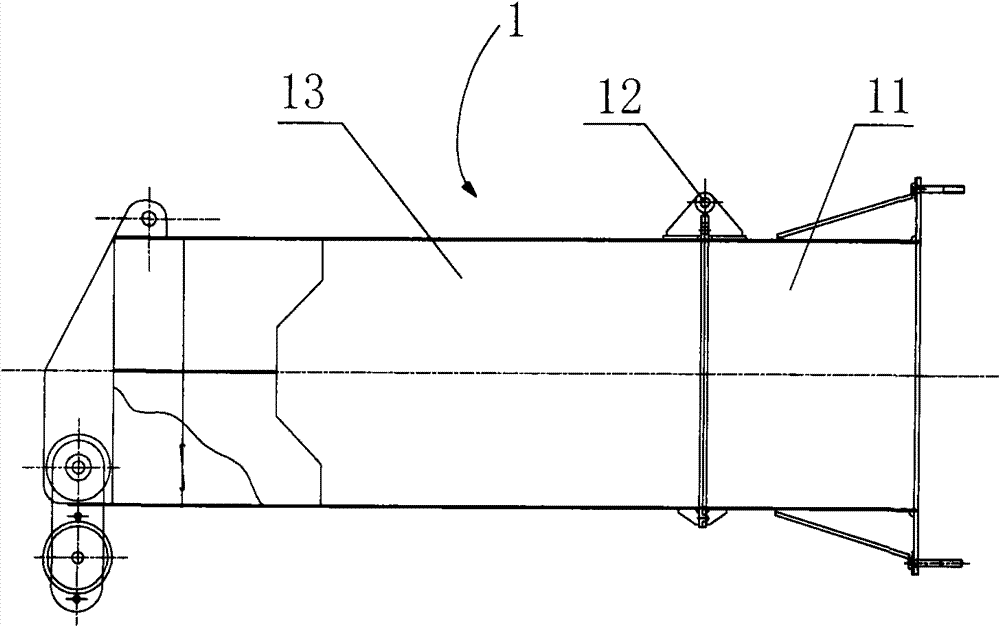

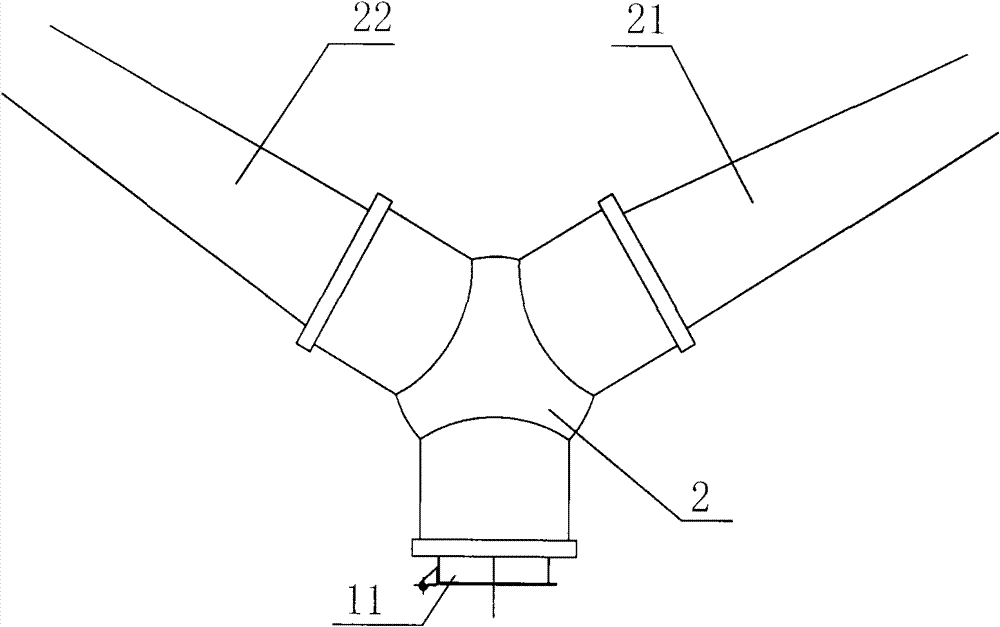

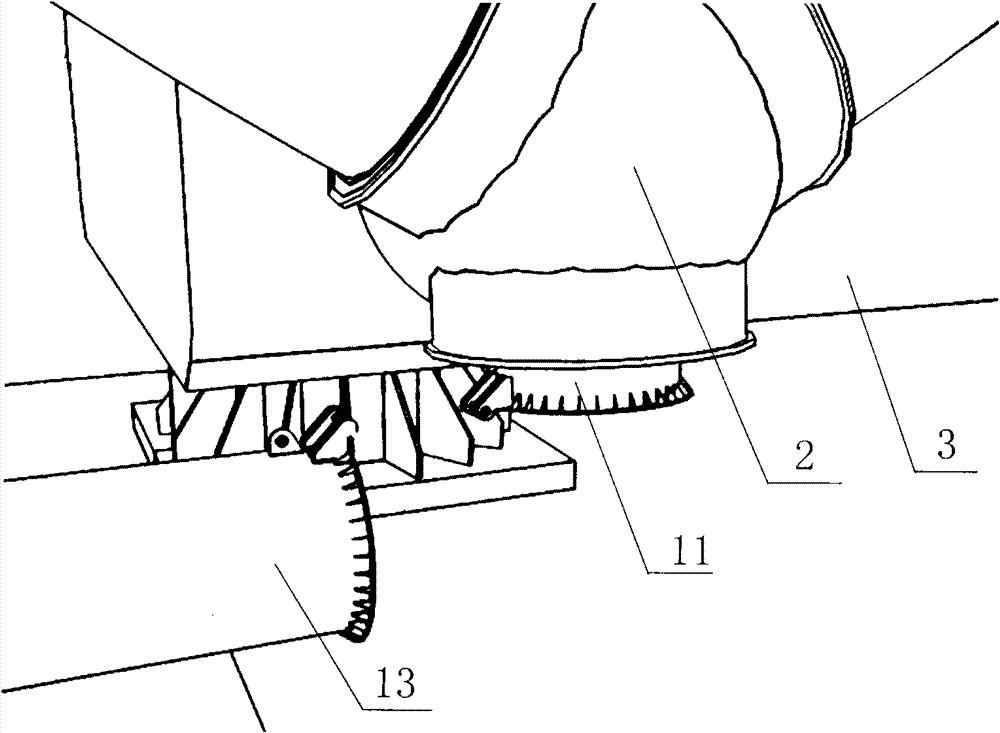

[0031] A. Prefabricate a tooling sleeve, the structure of the tooling sleeve 1 is as follows figure 1 As shown, it consists of detachable head and tail sections, the tail section 13 is connected to the end of the first section 11 by bolts, and a rotatable pivot pin 12 is also connected between the head and tail sections of the frock sleeve. . First fix the first section of the tooling sleeve in a blade installation hole on the hub, and thread a rope on the tooling sleeve, hook the rope with a hook to install the hub to the nacelle, and then install the other blade on the hub Adjust the mounting hole to a horizontal position, lift the first blade horizontally with a hook, and ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com