Piezoelectric fan and cooling device

A piezoelectric fan and piezoelectric element technology, applied in piezoelectric devices/electrostrictive devices, circuits, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem of increased heat generation and internal ventilation of electronic equipment Improve the cooling capacity and improve the air supply capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0085] Next, the piezoelectric fan according to Embodiment 1 of the present invention will be described.

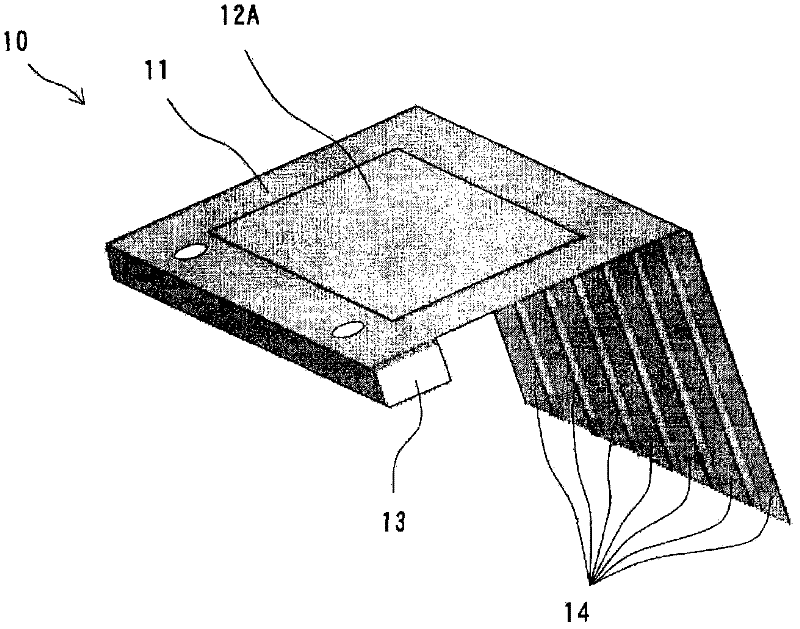

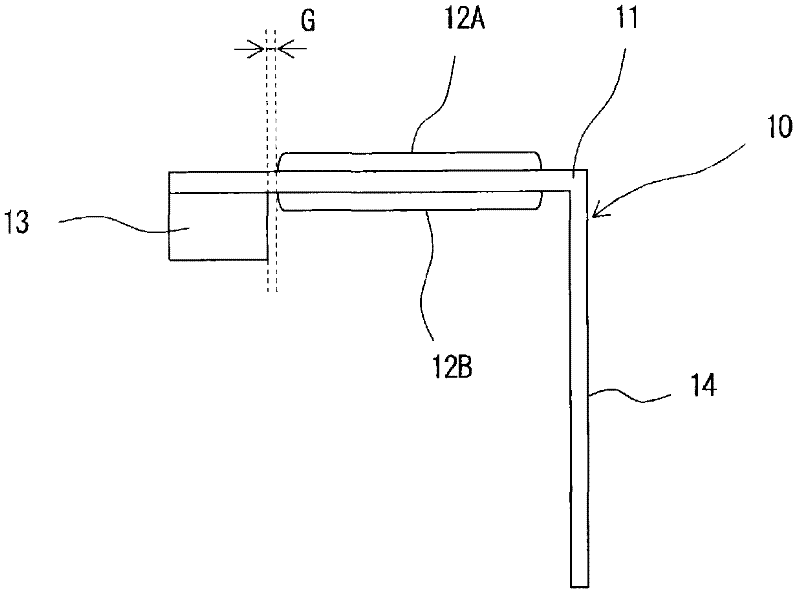

[0086] Figure 4 It is a perspective view showing the structure of the piezoelectric fan 101 according to the first embodiment, Figure 5 It is a side view showing the structure of the same piezoelectric fan 101 . Image 6 It is a perspective view which shows the structure of the cooling apparatus 1 provided with the same piezoelectric fan 101. also, Figure 5 The side view of the vibrating plate is a side view of the vibrating plate from a direction in which the boundary between the piezoelectric element and the fixing member can be seen. Here, the gap G is drawn to be slightly larger than the actual gap in order to easily describe the gap between the piezoelectric element and the fixed member at the boundary that can be seen.

[0087] Piezoelectric fan 101 includes vibrating plate 111 , piezoelectric elements 112A and 112B, fixing plate 113 , and reinforcing plates ...

Embodiment approach 2

[0109] Figure 8 (A) is a plan view showing the structure of the fixing plate 213 of the piezoelectric fan 201 according to the second embodiment, Figure 8 (B) is a front view showing the structure of the same fixing plate 213, Figure 8 (C) is a side view showing the structure of the same fixing plate 213 . in addition, Figure 9 It is a plan view showing the structure of the piezoelectric fan 201 according to the second embodiment, Figure 10 It is a side view showing the structure of the same piezoelectric fan 201 . also, Figure 10 The side view of the vibrating plate is a side view of the vibrating plate from a direction in which the boundary between the piezoelectric element and the fixing member can be seen.

[0110] In the piezoelectric fan 101 according to the first embodiment, the reinforcing plates 151 and 152 are provided in order to improve the rigidity of the section of the gap G on the diaphragm 111 , but the piezoelectric fan 201 of the present embodiment...

Embodiment approach 3

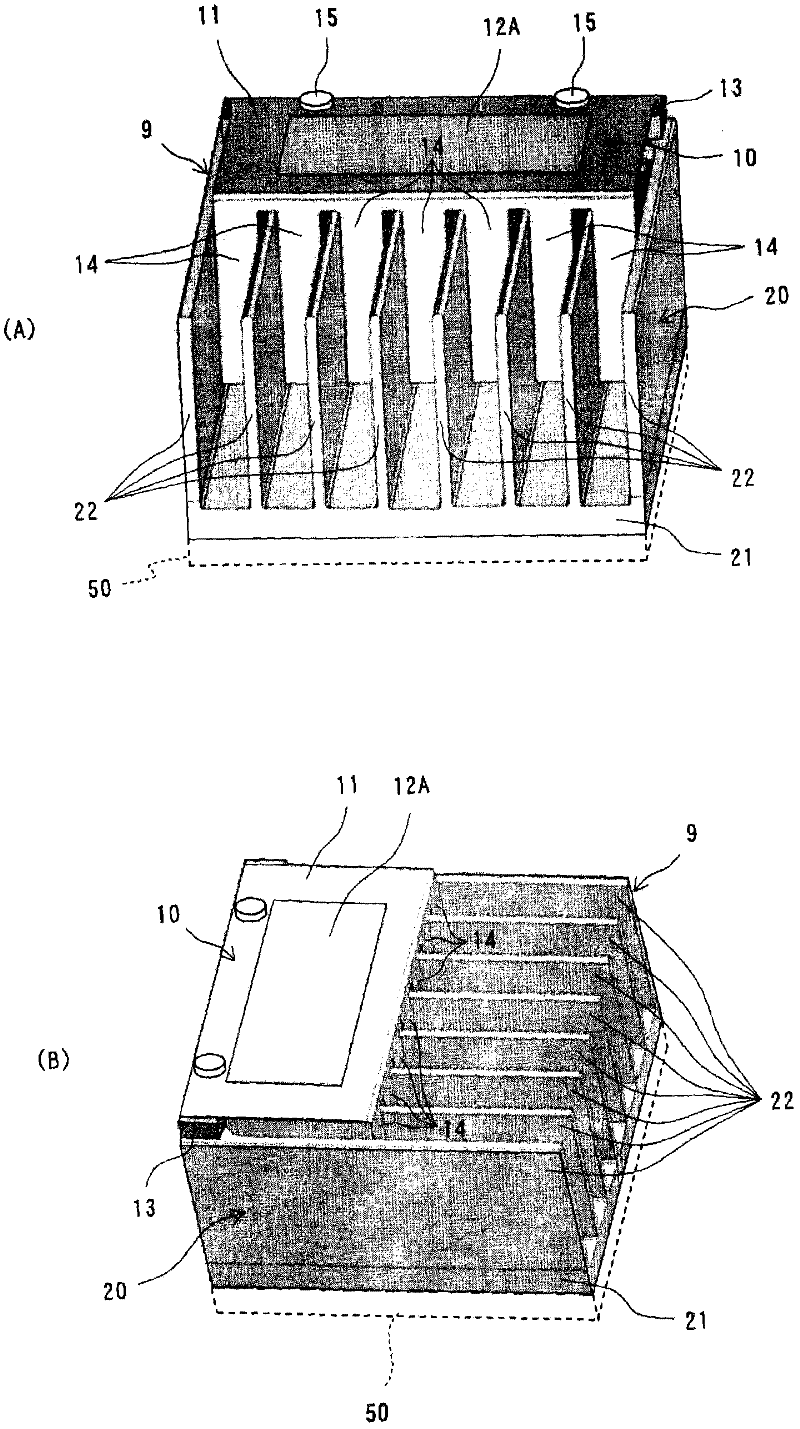

[0118] Figure 11 It is a perspective view which shows the structure of the piezoelectric fan 30 which is a modification of the piezoelectric fan 10 of a comparative example. Figure 12 It is a perspective view showing the structure of the piezoelectric fan 301 according to the third embodiment, Figure 13 It is a side view showing the structure of the same piezoelectric fan 301 . Figure 14 It is a perspective view which shows the structure of the cooling apparatus 3 provided with the same piezoelectric fan 301.

[0119] also, Figure 13 The side view of the vibrating plate is a side view of the vibrating plate from a direction in which the boundary between the piezoelectric element and the fixing member can be seen.

[0120] First, in order to compare the air blowing capability of the piezoelectric fan 30 as a modification of the piezoelectric fan 10 with the air blowing capability of the piezoelectric fan 301 of the present embodiment, the configuration of the piezoelect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com