Pipe joint

A technology for pipe joints and covers, applied in the field of pipe joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

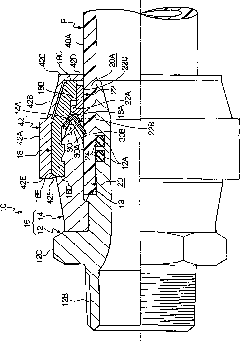

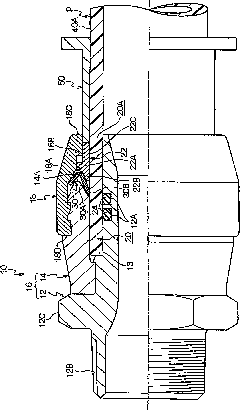

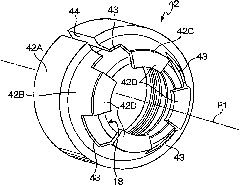

[0041] Below, based on Figure 1 to Figure 4 One embodiment of the present invention will be described.

[0042] figure 1 , represents the state after the pipe fitting in one embodiment of the present invention joins the pipe. figure 2 expressed in figure 1 The state where the tool is inserted into the fitting is shown.

[0043]Such as figure 1 and figure 2 As shown, the joint body 16 of the pipe joint 10 is composed of a tubular main body portion 12 and a tubular middle portion 14 sleeved outside the main body portion 12 . In addition, the pipe joint 10 includes a tubular cover body 18 that is sleeved on the outside of the middle part 14. Between the middle part 14, the cover body 18 and the main body part 12, a pipe P (for example, a polybutylene pipe) as a pipe body is formed to be inserted. The insertion hole 20.

[0044] A lock ring 30 for holding the pipe P in the insertion hole 20 is arranged inside the cover body 18 . The cross section of the lock ring 30 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com