Control unit provided with locking system for controlling shafts

A control unit and locking technology, applied in the field of component assembly, can solve problems such as difficulty in vehicle maintenance, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

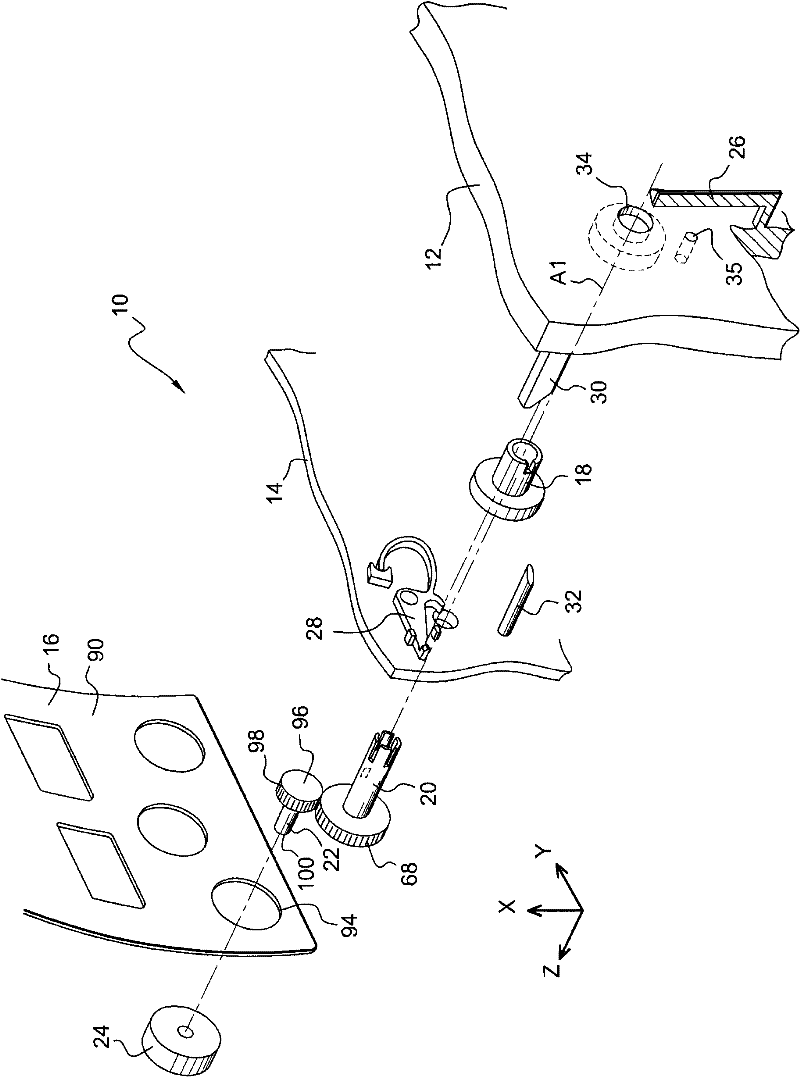

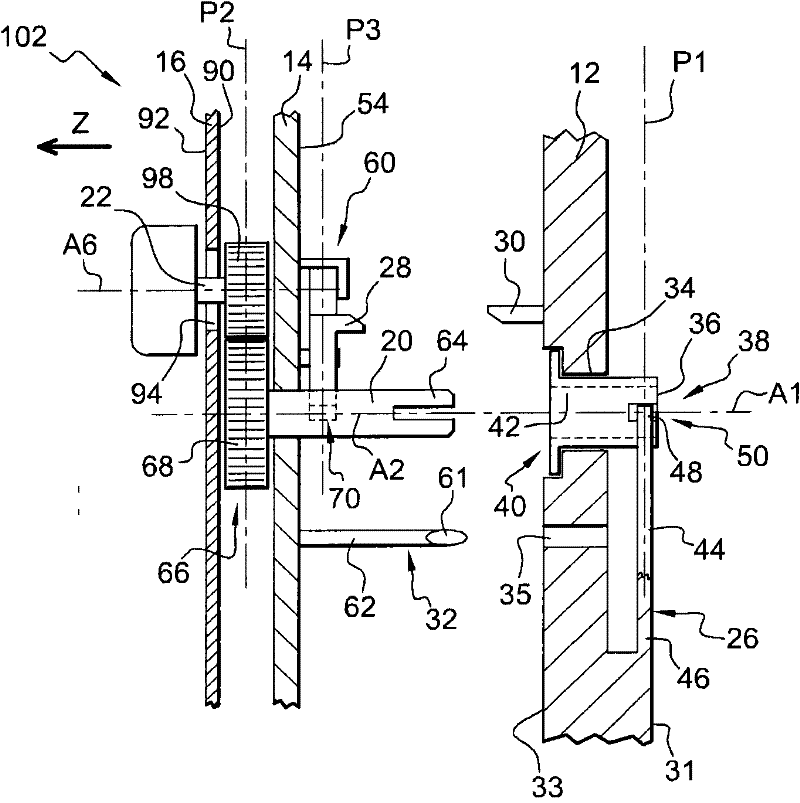

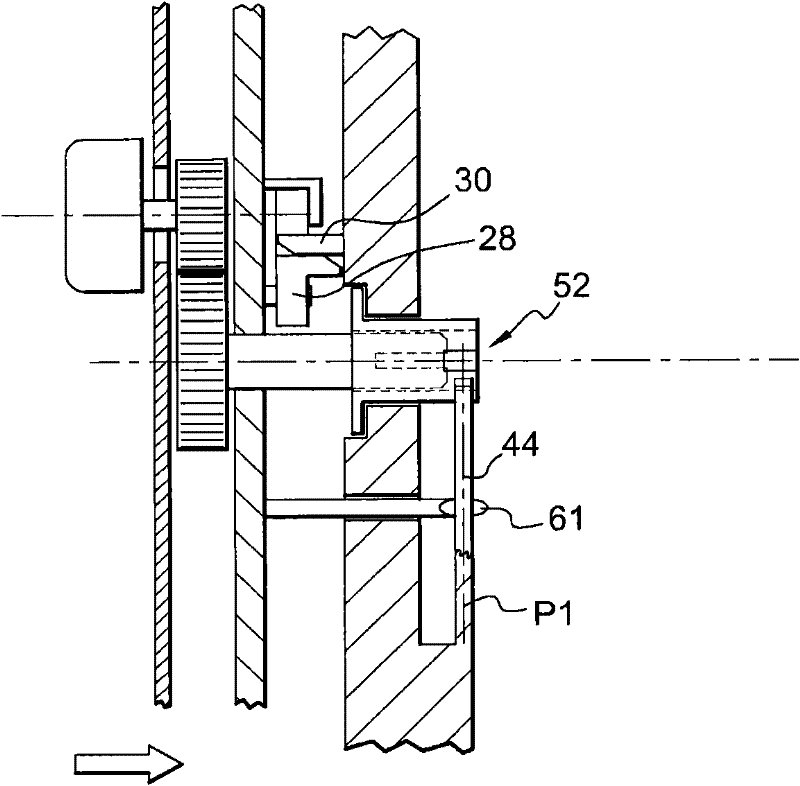

[0021] The invention will now be described by way of example with reference to the accompanying drawings.

[0022] In a non-limiting manner, the present description is described in a system of vertical axes X-Y-Z such that the assembly axis Z is oriented from "inside" to "outside" as figure 1 shown.

[0023] The control unit 10 of a vehicle air conditioning system with mechanical control (not shown) comprises, along an assembly axis Z from the inside to the outside, a stack of a base body 12, an intermediate panel 14 and a trim panel 16 substantially parallel to the main plane X-Y.

[0024] The control unit 10 is also provided with three shafts 18, 20, 22 oriented perpendicular to the main plane X-Y and extending along their respective axes parallel to the assembly axis Z, and when rotated co-operate. The inner shaft 18 actuates the mechanical control and is rotatably mounted relative to the base body 12 . The intermediate shaft 20 is rotatably mounted relative to the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com