Semiconductor packaging device with resin material loading photoelectric detection device

A technology for photoelectric detection and packaging equipment, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc. It can solve the problems of high use cost and complex resin structure, and achieve the effect of saving manufacturing cost and use cost, and simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

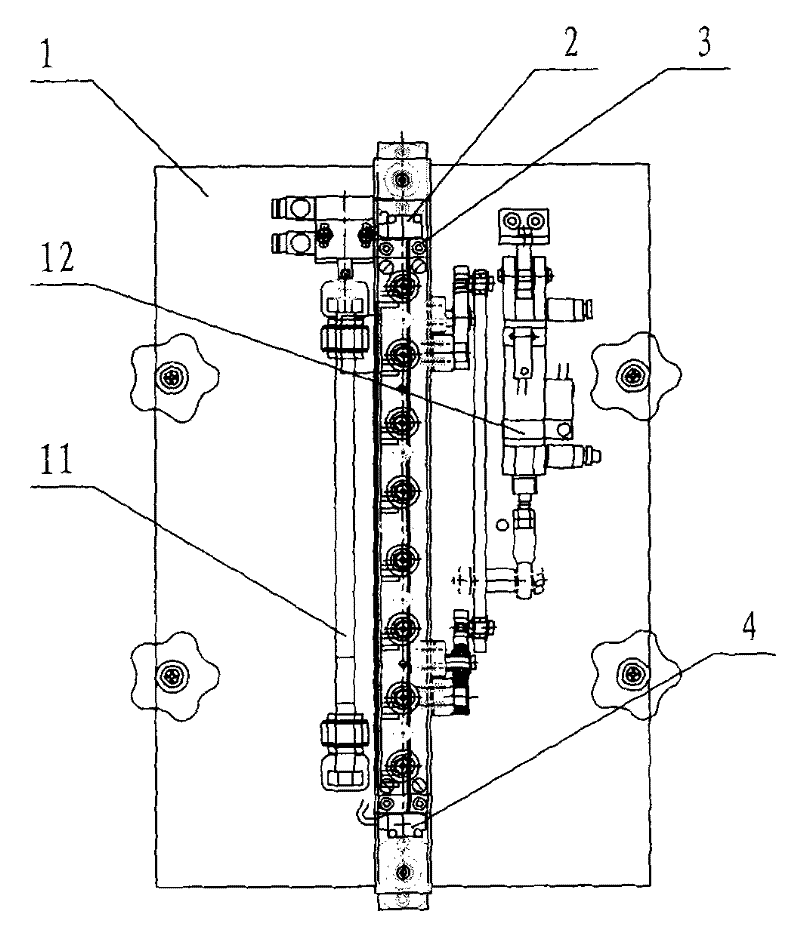

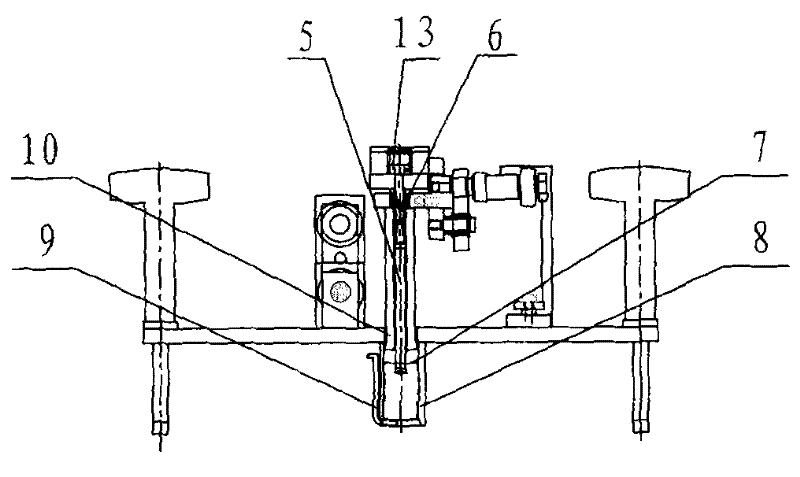

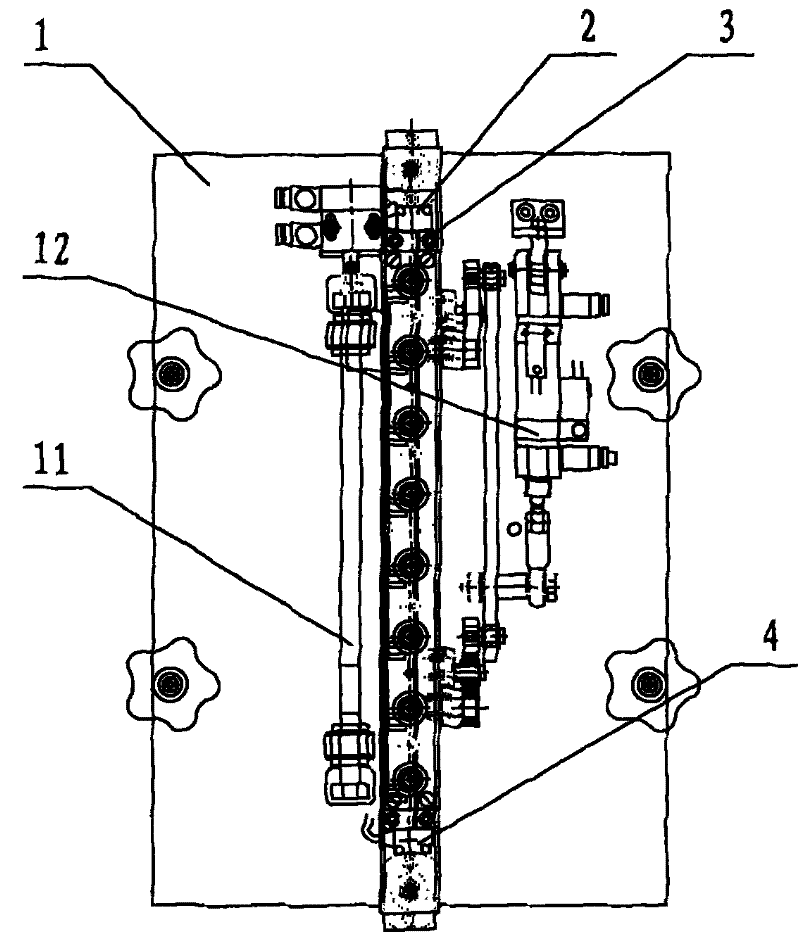

[0010] The present invention is a semiconductor packaging device with a photoelectric detection device for resin feeding, which includes a support plate 1, a resin push-out mechanism 12 and a resin baffle mechanism 11 fixed on the support plate 1, and a storage device located under the support plate 1 for storing The resin seat 8 of the resin 7, and the resin baffle plate 9 used to block the resin 7, are connected with the resin push-out mechanism and connected to several push tubes 10 for pushing the resin 7 through the support plate 1 and extending into the resin seat 8, It is characterized in that it also includes a resin feeding photoelectric detection device fixed on the support plate.

[0011] The photoelectric detection device for resin feeding comprises a photoelectric emission sensor 2, a photoelectric receiving sensor 4 adapted to the photoelectric emission sensor 2, several thimbles 5 and a strip-shaped emission channel plate 3 positioned in the push tube 10, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com