Oxygen-enriched membrane oxygen generation device

An oxygen-generating device and an oxygen-enriched membrane technology, which are applied in the fields of oxygen preparation, oxygen/ozone/oxide/hydroxide, inorganic chemistry, etc., can solve the problems of inability to supply high-concentration oxygen for a long time, high maintenance and replacement costs, and Oxygen results and other problems, to achieve the effect of easy replacement, reduce manufacturing cost and use cost, and improve user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

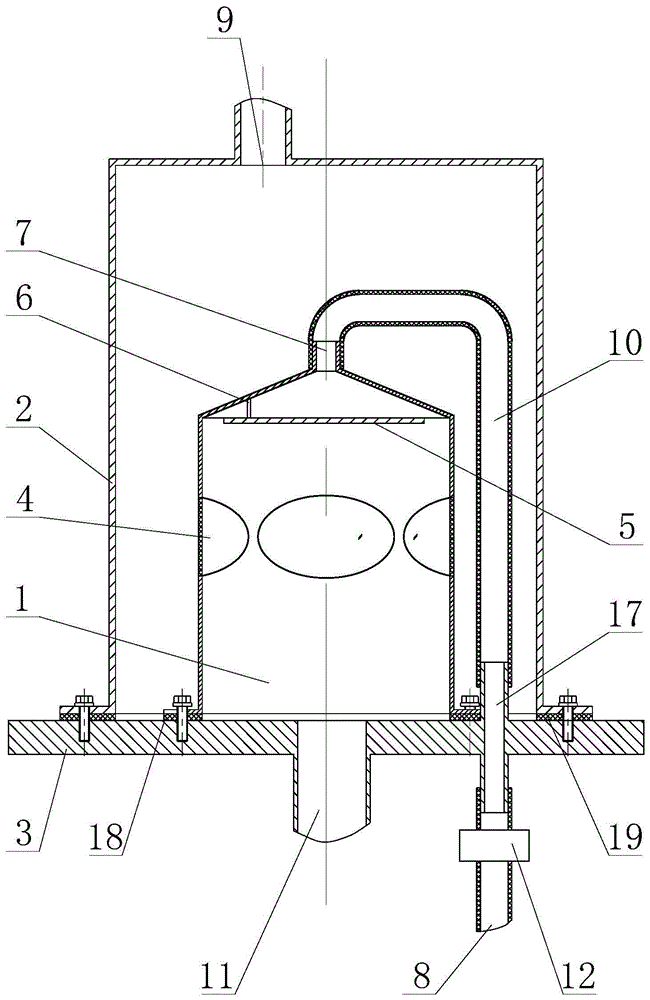

[0037] The present invention will be further elaborated below in conjunction with specific drawings and embodiments.

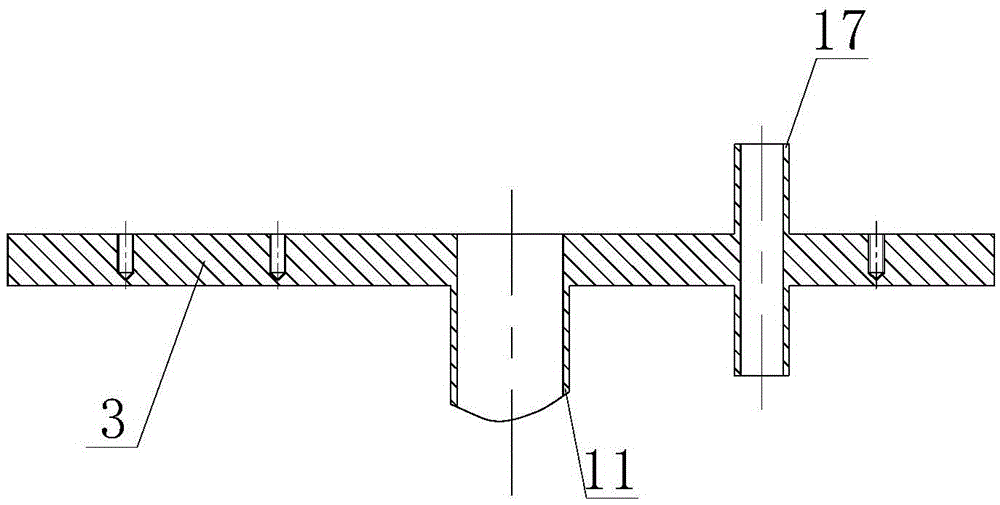

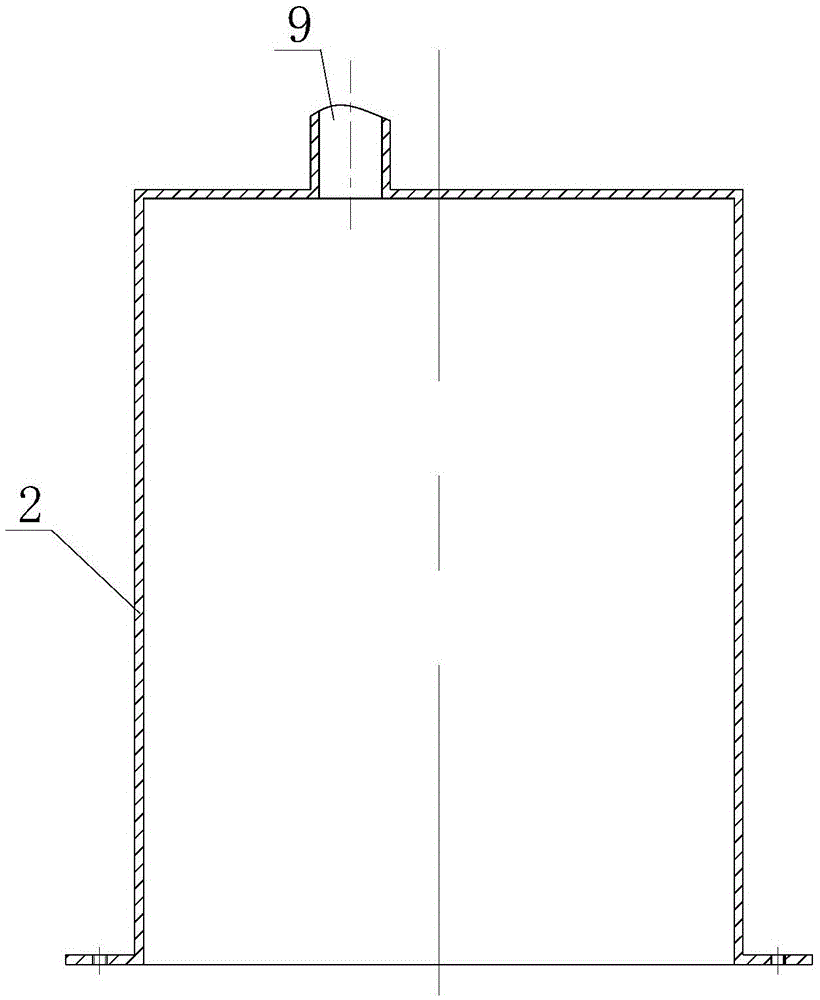

[0038] like figure 1 As shown, the device includes an inner cabin body 1 and an outer cabin body 2 housed inside and outside, and a cabin body seat 3 that is sealed and covered inside, and the bottom openings of the cabin body 1 and the outer cabin body 2 in the outer cabin body. Both the inner cabin body 1 and the outer cabin body 2 are in the shape of a reversed barrel, and the edge of the barrel mouth is turned outwards to form a circle of turned edges. Sealing washer 19, the second sealing washer 18 is arranged between the turned edge of the inner cabin body 1 and the cabin body seat 3, and is locked with bolts respectively. It not only has good sealing performance, but also facilitates disassembly and assembly of the device, internal cleaning and maintenance, and replacement of the oxygen-enriched membrane.

[0039] The cabin seat 3 inside the inner cabin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com