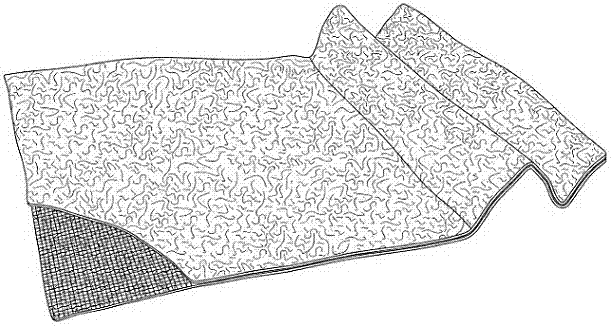

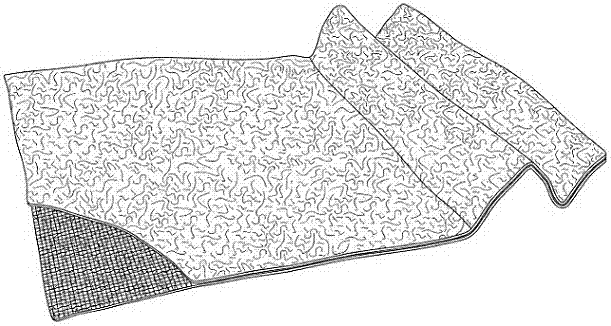

Filter bag, pleatable filtration material therefore, and process of making same

A filter material and filter bag technology, applied in the field of filtration, can solve problems such as non-pleating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] PTFE fibers were hydroentangled at 400 g / m 2 stainless steel mesh. Overall density after entanglement is 800 g / m 2 . The material in this step has a permeability of about 200 l / dm 2 / min. The resulting felt support material was sprayed with a suspension of FEP particles, dried at a temperature of 150°C and added with approximately 25 g / m of FEP particles. The film was then laminated on felt while the temperature of the FEP pellets was raised to 270°C. The resulting filter material has 825 g / m 2 density, and a permeability of 15-30 l / dm2 / min at 12 mm water gauge, and is pleatable at room temperature.

Embodiment 2

[0031] Titanium dioxide particles with a particle size of less than 10 microns are mixed with the PTFE dispersion. Titanium dioxide may correspond to 1-90% by volume, preferably 25-85% by volume, the paste is extruded and calendered to form ribbons which are split along the length, expanded, and processed with rotating pinwheels . These fibers with catalyst on the surface were hydroentangled onto stainless steel 316 mesh by hydroentangling. Total density reaches 900 g / m after entanglement 2 . The E-PTFE membrane was directly laminated onto the surface of the catalyst felt, and the fibers were used as the bonding agent. The resulting material has a 900 g / m 2 Density, 15~30 l / dm2 / min permeability at 12 mm water gauge, and pleatable at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com