Connector removing jig and connector removing method using the same

A connector and unclamping technology, which is applied to the parts of the connecting device, the connection/disconnection of the connecting device, and the connection direction, which can solve problems such as difficulty in operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

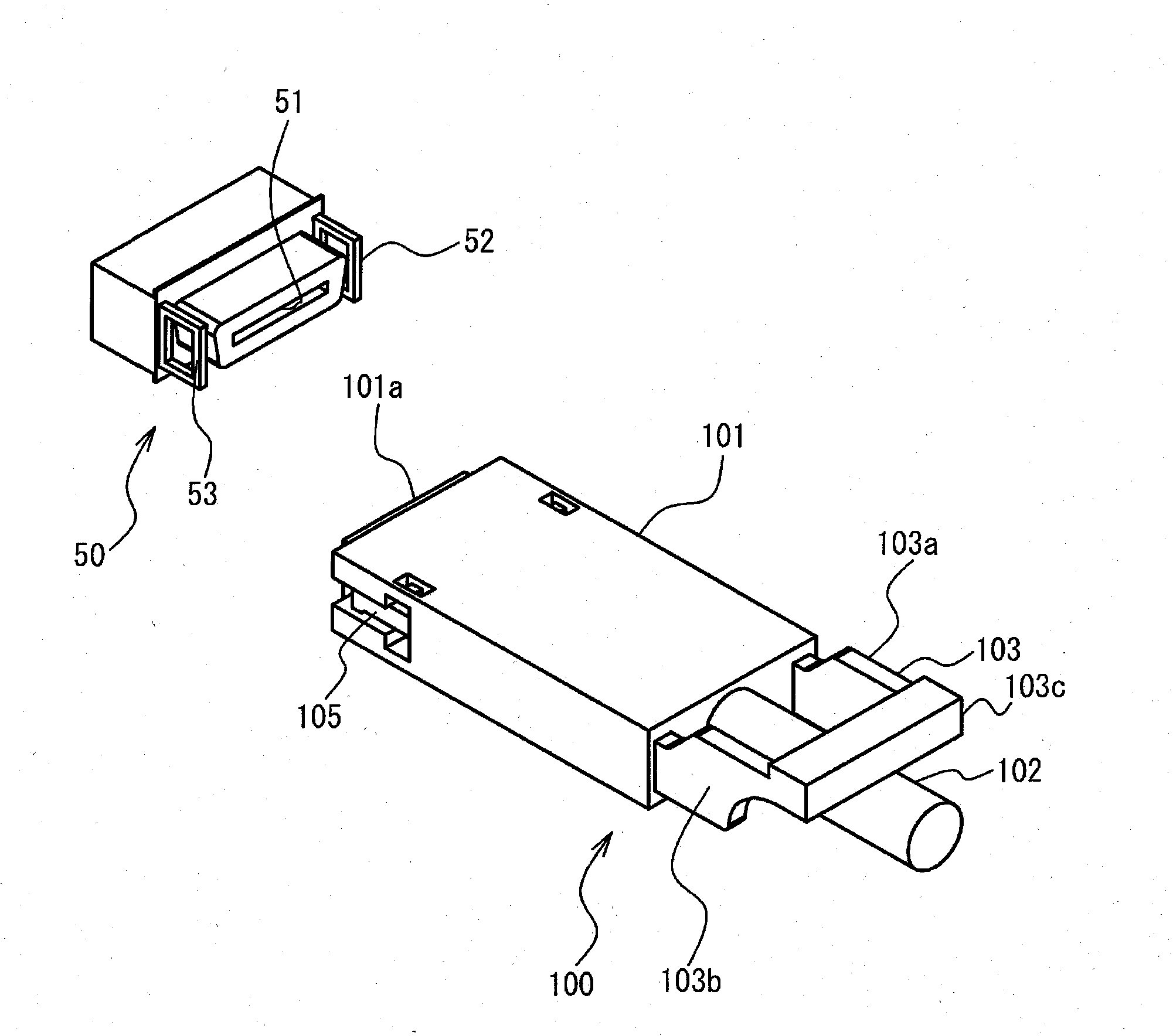

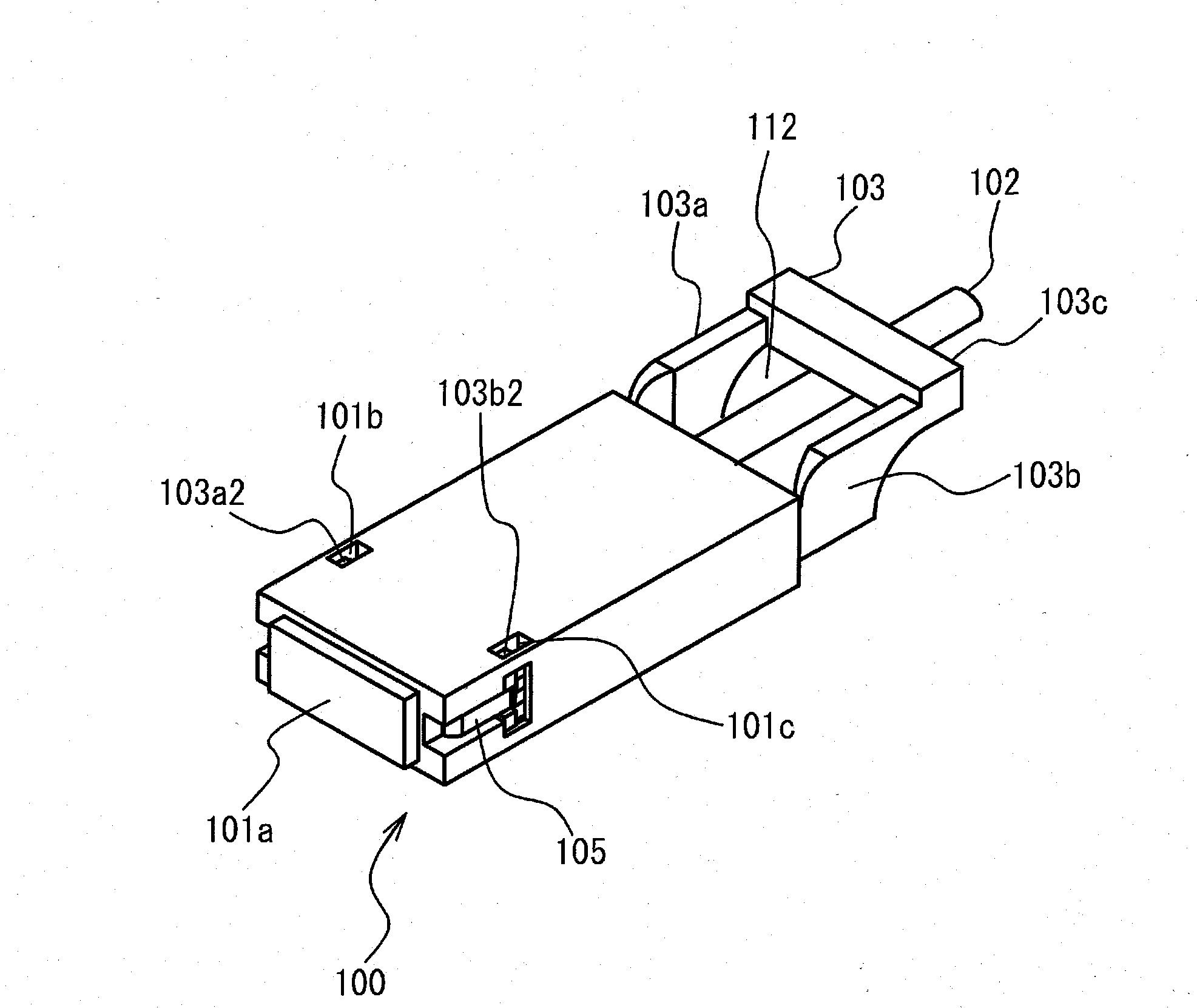

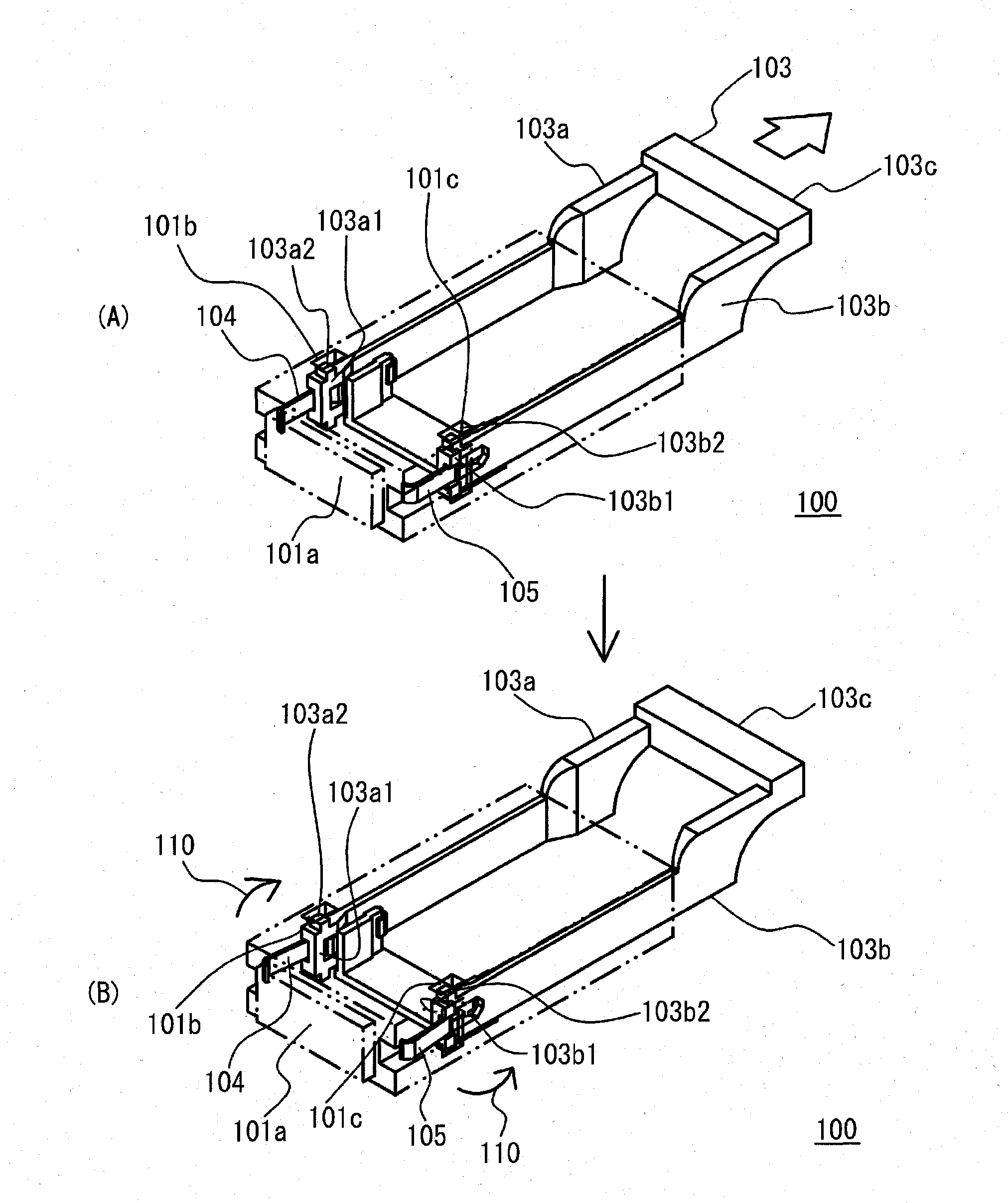

[0029] First, for ease of understanding Figure 7 The pull-off jig 1 of the present embodiment described in, refer to Figure 1 to Figure 5 (B) The cable-side connector 100 that can be detached using the detaching jig 1 will be described.

[0030] figure 1 It is a perspective view of the board-side connector 50 and the cable-side connector 100 . figure 2 for following with figure 1 A perspective view of the cable-side connector 100 viewed from a different side. image 3 (A) and 3(B) are perspective views of the interior of the cable-side connector 100 . image 3 (A) is a figure which shows the state which the 1st engaging claw 104 and the 2nd engaging claw 105 are closed, image 3 (B) is a figure which shows the state which the 1st engaging claw 104 and the 2nd engaging claw 105 opened. Figure 4 (A) and 4(B) are from and image 3 (A) and 3(B) are perspective views of the interior of the cable-side connector 100 viewed from different sides. Figure 4 (A) is a figure w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com