Self-connection type high-sealing-performance ball valve

A high-tightness, one-piece technology, applied in valve details, valve devices, valve heating/cooling devices, etc., to achieve the effects of prolonging working life, preventing fluid leakage, and improving wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

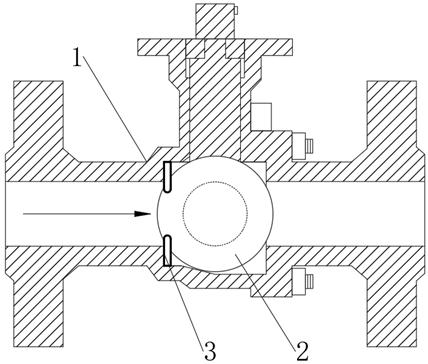

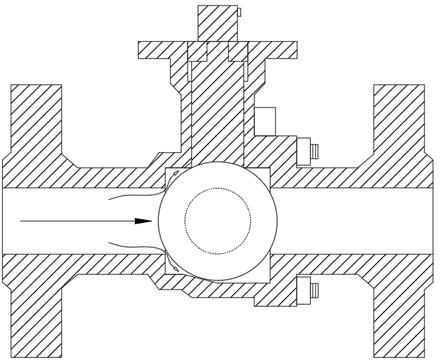

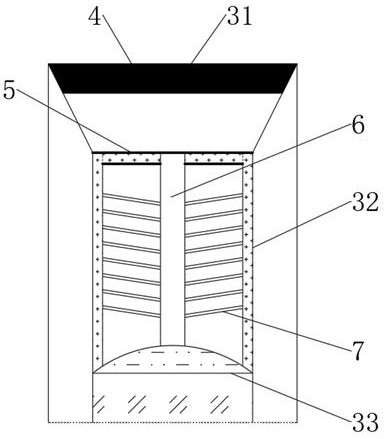

[0043] see Figure 1-3 , a self-joined ball valve with high sealing performance, including a valve body 1, a valve core 2 is movable installed in the valve body 1, a one-piece sealing ring 3 is fixedly connected to the side close to the water inlet in the valve body 1, and the valve core 2 The outer end is provided with a conjoined ring groove 8 corresponding to the one-piece sealing ring 3. The one-piece sealing ring 3 includes a base part 31, a mid-phase change capsule 32 and an inner water storage ring 33, and the base part 31, the mid-phase change capsule 32 and the inner water storage ring 33 are sequentially connected from outside to inside, an electromagnet 4 is installed at the inner end of the base part 31, a separation belt 5 is fixedly connected between the base part 31 and the intermediate phase change capsule 32, and an electric heater is inserted on the separation belt 5 wire 6, and the electric heating wire 6 extends to the inner side of the phase change capsule...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com