Air valve bridge assembly, in-cylinder brake system and engine

A valve bridge and assembly technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of increased engine weight, affected braking power, insufficient brake exhaust valve 8 lift, etc. Dynamic load, improved reliability, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

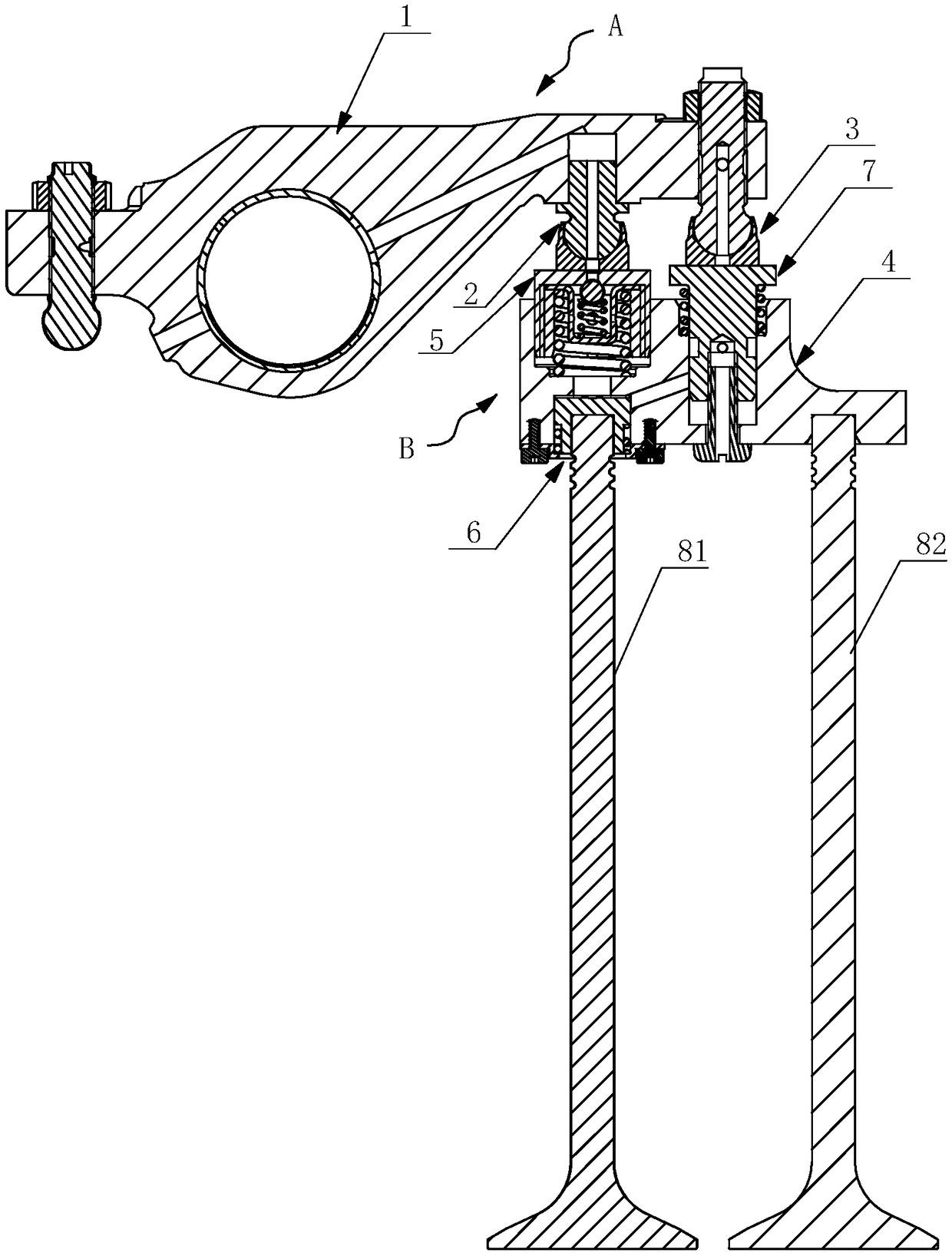

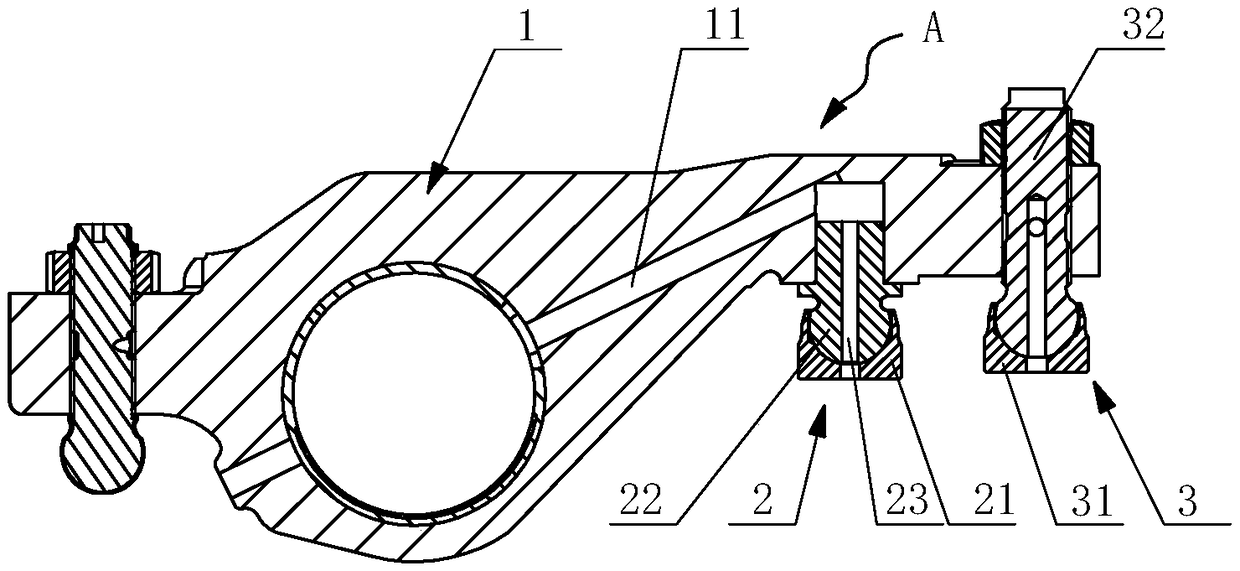

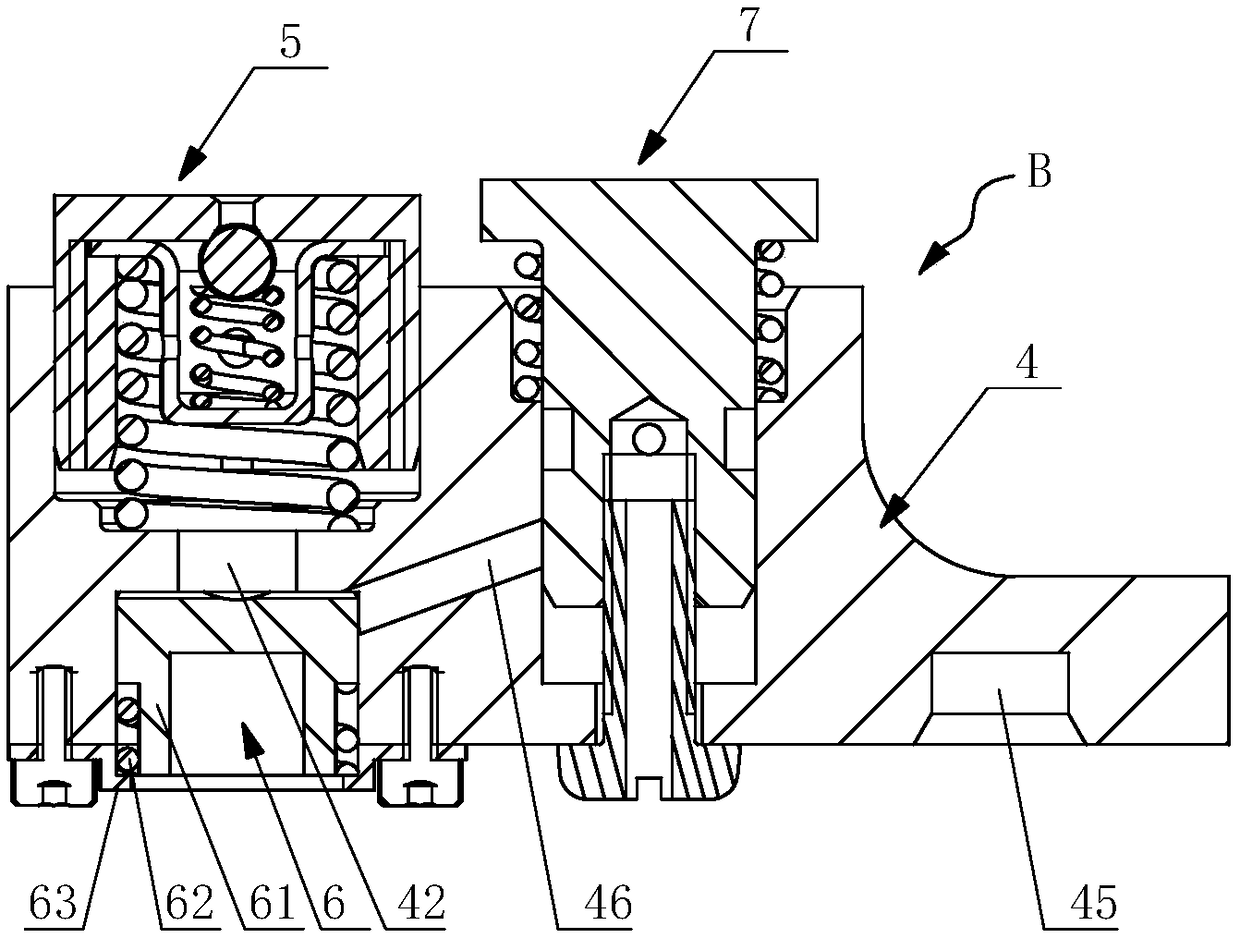

[0055] The core of the present invention is to provide a valve bridge assembly, which greatly reduces the braking load and improves the reliability of the gas distribution mechanism under braking conditions during the compression release braking process.

[0056] The present invention also provides an in-cylinder braking system comprising the valve bridge assembly and an engine comprising the in-cylinder braking system, which greatly reduces the braking load and improves the braking performance during the compression release braking process. The reliability of the valve train under certain conditions.

[0057] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com