High-performance sound-absorbing damping soft porcelain decorative material and preparation method thereof

A decorative material and high-performance technology, applied in the field of building decorative materials, can solve the problems of insufficient mechanical properties, sound insulation effect, unfavorable industrial mass production, unfavorable large-scale production, etc. The effect of increased sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

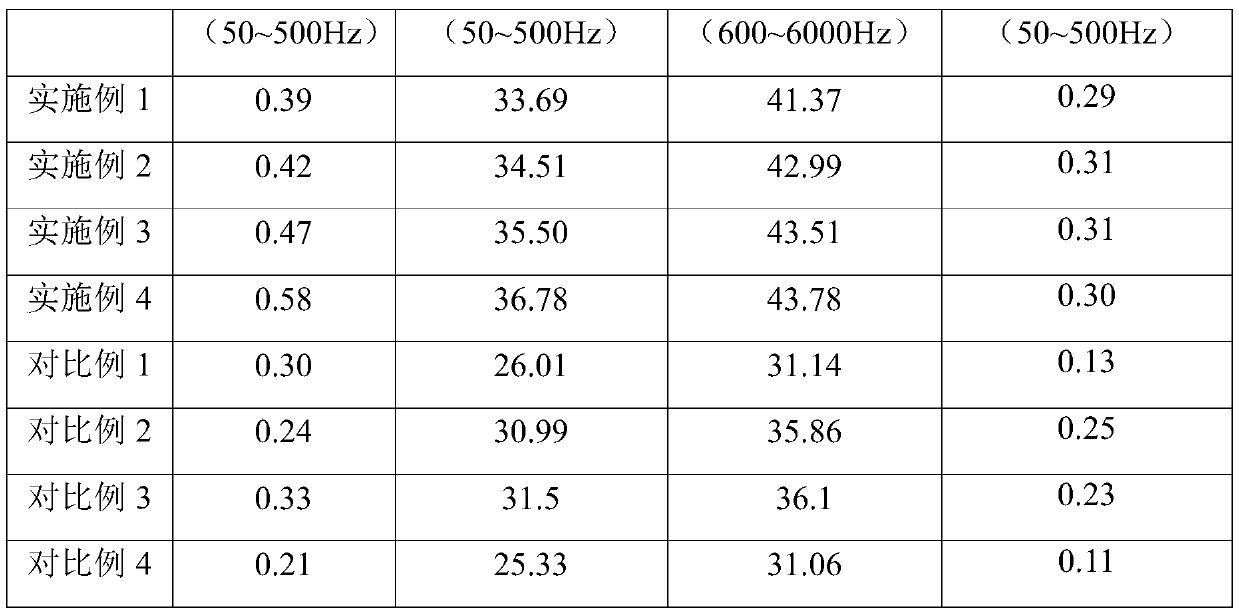

Examples

Embodiment 1

[0039] A high-performance sound-absorbing and damping soft porcelain decorative material, the preparation method of which comprises the following steps:

[0040] (1) Preparation of soft porcelain facing layer:

[0041] Weigh 10 parts of cement and 30 parts of quartz sand, add them into a kneader, mix them evenly, and obtain a mixed powder; Add 10 parts of water into the stirring tank and stir evenly to obtain a mixed emulsion; then add the mixed powder to the mixed emulsion and stir thoroughly to obtain a slurry; finally pour the slurry into a mold and dry it in an oven at 120°C 1h, obtain the soft porcelain veneer layer;

[0042] (2) Preparation of soft porcelain veneer layer and sound-absorbing layer:

[0043] Weigh 10 parts of cement, 30 parts of quartz sand, 20 parts of ceramsite and polypropylene fiber, add them to a kneader, mix evenly, and obtain a mixed powder; weigh 10 parts of silicon acrylic emulsion, 5 parts of ammonium polyphosphate, 0.5 parts Add KH-550 and 10...

Embodiment 2

[0047] A high-performance sound-absorbing and damping soft porcelain decorative material, the preparation method of which comprises the following steps:

[0048] (1) Preparation of soft porcelain facing layer:

[0049] Weigh 12 parts of cement and 33 parts of quartz sand, add them to a kneader, mix them evenly, and obtain a mixed powder; Add 16 parts of water into the stirring tank and stir evenly to obtain a mixed emulsion; then add the mixed powder to the mixed emulsion and stir thoroughly to obtain a slurry; finally pour the slurry into a mold and dry it in an oven at 55°C 1h, obtain the soft porcelain veneer layer;

[0050] (2) Preparation of soft porcelain veneer layer and sound-absorbing layer:

[0051] Weigh 11 parts of cement, 36 parts of quartz sand, 25 parts of ceramsite and polypropylene fiber, add them to a kneader, mix evenly, and obtain a mixed powder; weigh 16 parts of silicon acrylic emulsion, 6 parts of ammonium polyphosphate, 0.6 parts Add KH-550 and 17 pa...

Embodiment 3

[0055] A high-performance sound-absorbing and damping soft porcelain decorative material, the preparation method of which comprises the following steps:

[0056] (1) Preparation of soft porcelain facing layer:

[0057] Weigh 26 parts of cement and 37 parts of quartz sand, add them into a kneader, mix them evenly, and obtain a mixed powder; Add 20 parts of water into the stirring tank and stir evenly to obtain a mixed emulsion; then add the mixed powder to the mixed emulsion and stir thoroughly to obtain a slurry; finally pour the slurry into a mold and dry it in an oven at 55°C 4h, obtain the soft porcelain veneer layer;

[0058] (2) Preparation of soft porcelain veneer layer and sound-absorbing layer:

[0059] Weigh 28 parts of cement, 43 parts of quartz sand, 40 parts of ceramsite and polypropylene fiber, add them to a kneader, mix evenly, and obtain a mixed powder; weigh 25 parts of silicon acrylic emulsion, 8 parts of ammonium polyphosphate, 1.2 parts KH-550 and 22 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com