Pressure-sensitive adhesive layer for transparent conductive film, transparent conductive film with pressure-sensitive adhesive layer, transparent conductive laminate, and touch panel

一种透明导电性膜、透明导电性的技术,应用在绝缘载体上的导电层、粘合剂类型、酯共聚物粘合剂等方向,能够解决经时变化差、操作温度范围窄等问题,达到抑制腐蚀、耐久性良好、高内聚力性的效果

- Summary

- Abstract

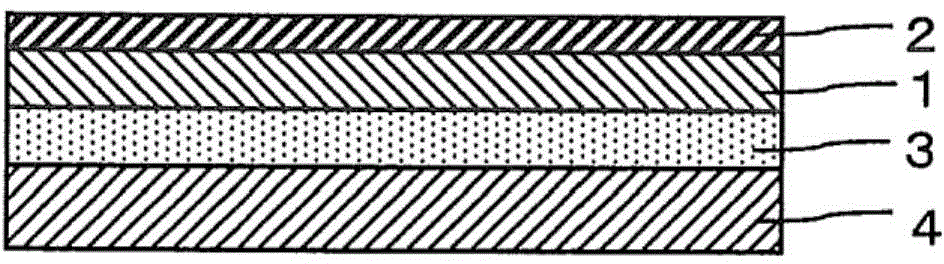

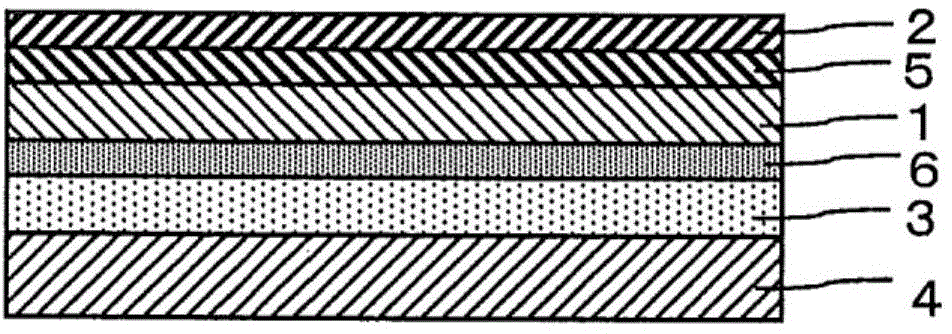

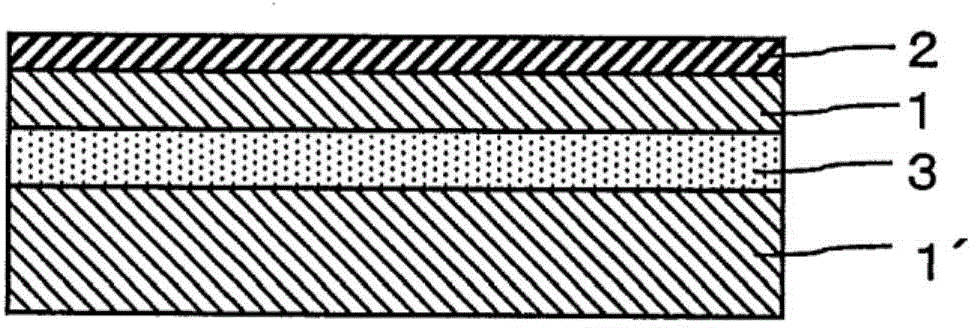

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0118] (Preparation of aqueous dispersion)

[0119] Add 1000 parts of butyl acrylate, 50 parts of acrylic acid, 23 parts of mono[poly(oxypropylene) methacrylate] phosphate (the average degree of polymerization of propylene oxide is 5.0), and 0.34 parts of 3-methacryloyloxy Triethoxysilane (manufactured by Shin-Etsu Chemical Co., Ltd., KBM-503) was used as a raw material and mixed to obtain a monomer mixture. Next, 13 parts of Aqualon HS-10 (manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.) as a reactive emulsifier and 360 parts of ion-exchanged water were added to 600 parts of the monomer mixture prepared in the above ratio, and a homogenizer (special Kikka Kogyo Co., Ltd.) was stirred at 7000 rpm for 3 minutes to prepare a monomer emulsion.

[0120] Then, 200 parts and 350 parts of ion-exchanged water in the monomer emulsion prepared above were put into a reaction vessel equipped with a condenser tube, a nitrogen gas introduction tube, a thermometer, a dropping funnel,...

Embodiment 2

[0134] The addition amount of the ammonia water of concentration 10% in the (preparation of water dispersion type acrylic adhesive) in embodiment 1 is changed from 3 parts to 10 parts, the drying in the (formation of adhesive layer) of embodiment 1 Except that the conditions were changed from 130° C. for 10 minutes to 90° C. for 10 minutes, it was implemented in the same manner as in Example 1, and a transparent conductive film with an adhesive layer was produced.

Embodiment 3

[0136] Except that the addition amount of ammonia water with a concentration of 10% in Example 1 (preparation of water-dispersed acrylic adhesive) is changed from 3 parts to 0.5 parts, it is implemented in the same way as Example 1 to make a tape adhesive layer of transparent conductive film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com