Graphene fiber thermal insulation mesh fabric and preparation method thereof

A graphene fiber and graphene technology, applied in textiles, papermaking, building components, etc., can solve the problems of short service life of building insulation materials, insufficient structural reinforcement effect, limited application range, etc., achieve excellent anti-corrosion and reduce personnel costs , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

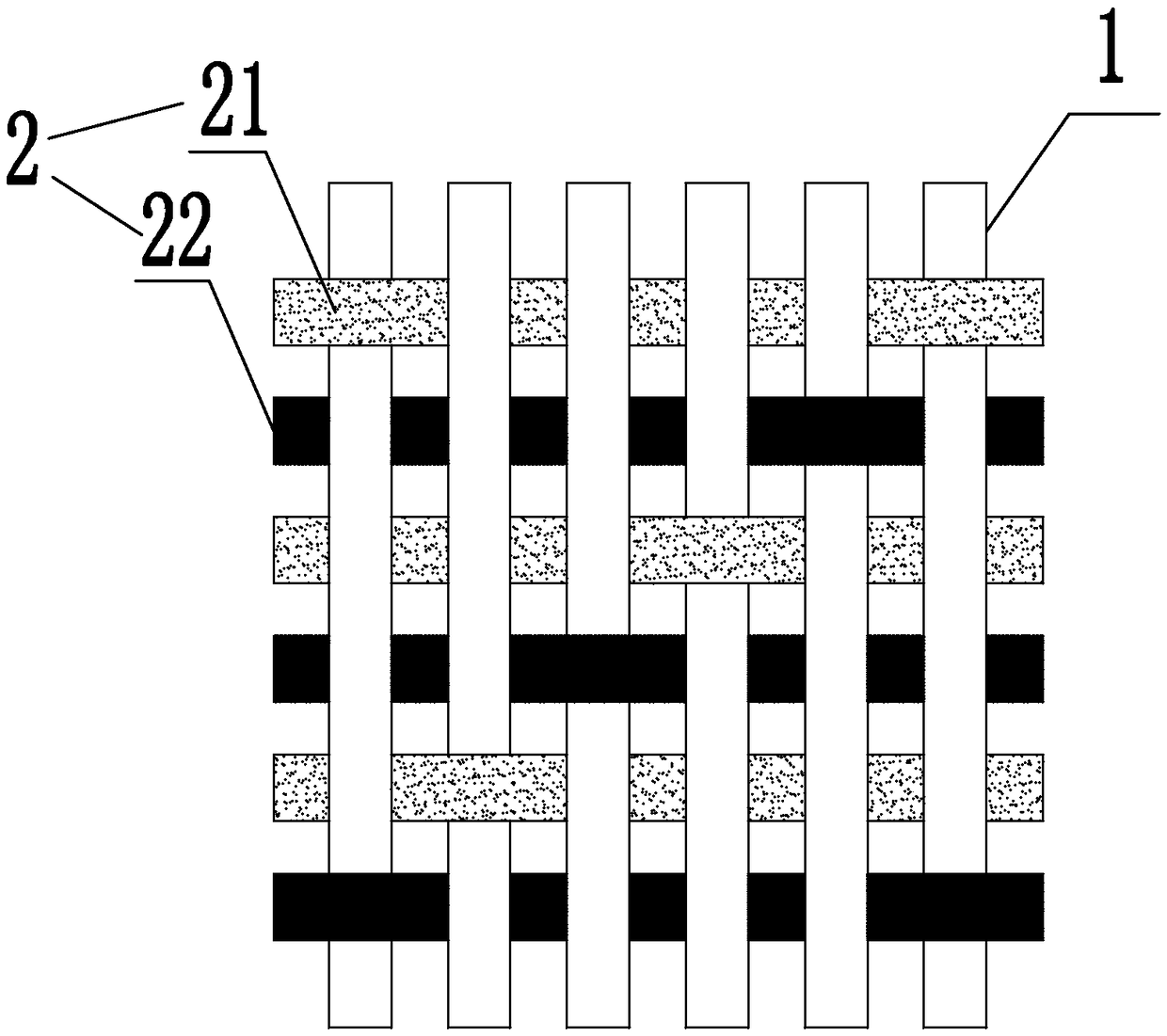

[0022] refer to figure 1 , a graphene fiber heat insulation grid cloth includes a group of graphene fiber heat insulation mesh units, and the graphene fiber heat insulation mesh unit is composed of fiber heat insulation mesh and its surface-coated graphene coating, The fiber heat insulation grid is woven from glass fiber and basalt fiber. Basalt fiber and glass fiber interweave each other, warp 1 is composed of basalt fiber yarn, weft 2 is alternately arranged with glass fiber yarn 21 and basalt fiber yarn 22 in a ratio of 1:1, warp 1 is wound up and down weft 2 Forming a fiber heat-insulation grid structure; then coating the graphene coating on the above-mentioned fiber heat-insulation grid, and then drying at 60° C. for 2 hours, and the thickness of the graphene coating is 150 μm.

[0023] The preparation method of described graphene coating is as follows:

[0024] Step1: Weigh 1 part of graphene, 70 parts of diallyl terephthalate, 240 parts of deionized water, and 0.3 par...

Embodiment 2

[0028] refer to figure 1 , a graphene fiber heat insulation grid cloth includes a group of graphene fiber heat insulation mesh units, and the graphene fiber heat insulation mesh unit is composed of fiber heat insulation mesh and its surface-coated graphene coating, The fiber heat insulation grid is woven from glass fiber and basalt fiber. Basalt fiber and glass fiber interweave each other, warp 1 is composed of basalt fiber yarn, weft 2 is alternately arranged with glass fiber yarn 21 and basalt fiber yarn 22 in a ratio of 1:1, warp 1 is wound up and down weft 2 Forming a fiber heat insulation grid structure; then coating the graphene coating on the above fiber heat insulation grid, and then drying at 70°C for 2.5h, the thickness of the graphene coating is 200μm.

[0029] The preparation method of described graphene coating is as follows:

[0030] Step1: Weigh 3 parts of graphene, 75 parts of diallyl terephthalate, 280 parts of deionized water, and 0.5 parts of benzylnaphtha...

Embodiment 3

[0034] refer to figure 1 , a graphene fiber heat insulation grid cloth includes a group of graphene fiber heat insulation mesh units, and the graphene fiber heat insulation mesh unit is composed of fiber heat insulation mesh and its surface-coated graphene coating, The fiber heat insulation grid is woven from glass fiber and basalt fiber. Basalt fiber and glass fiber interweave each other, warp 1 is composed of basalt fiber yarn, weft 2 is alternately arranged with glass fiber yarn 21 and basalt fiber yarn 22 in a ratio of 1:1, warp 1 is wound up and down weft 2 A fiber heat insulation grid structure is formed; then the graphene coating is coated on the above fiber heat insulation grid, and then dried at 80° C. for 3 hours, and the thickness of the graphene coating is 240 μm.

[0035] The preparation method of described graphene coating is as follows:

[0036] Step1: Weigh 5 parts of graphene, 80 parts of diallyl terephthalate, 320 parts of deionized water, and 0.6 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com