Rear lock of a brassiere

A bra and back technology, applied in the field of bras, can solve the problems of increasing the cost of known buckles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

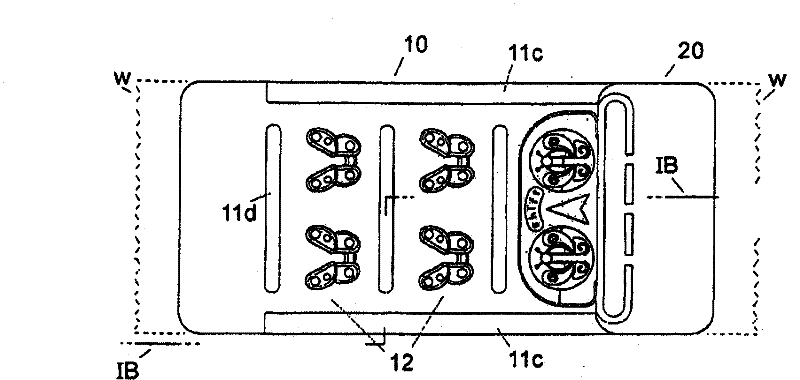

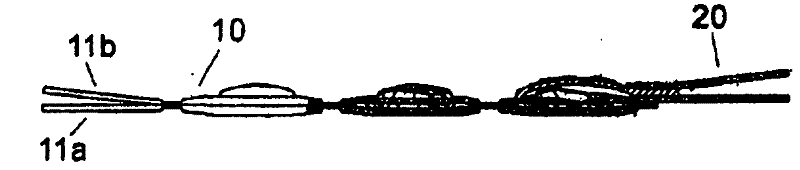

[0066] as by Figures 1A-1F As is obvious, a buckle according to the invention basically comprises a female part 10 and a male part 20, the female part being usually fastened on a back wing W marked with a dotted line, and the male part 20 The part is attached to the other back flank. Figure 1A The buckle is shown viewed from the rear, that is to say towards a position behind the wearer, wherein the buckle overlaps with its longest fit.

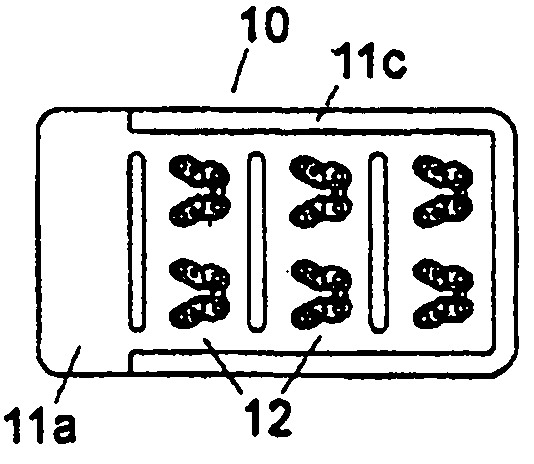

[0067] The concave part 10 consists of a front material layer 11a and a rear material layer 11b, at least one of which, in the embodiment shown, is two, is made of a non-extensible woven fabric, usually of a Composed of microfiber strips formed from linen. The layers 11a and 11b are connected to each other along their longitudinal edges and an outer edge by a U-shaped weld 11c. In addition, transversely extending welds 11d are provided, which are arranged at a distance from one another in the longitudinal direction, distributed over the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com