Apparatus for loading board-like body, and delivery vehicle

A technology of plate-shaped objects and device pairs, applied in the field of transport vehicles, can solve problems such as impracticality, achieve efficient stacking operations, and reduce transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, preferred embodiments of the plate-shaped object stacking device and the transport vehicle according to the present invention will be described based on the accompanying drawings.

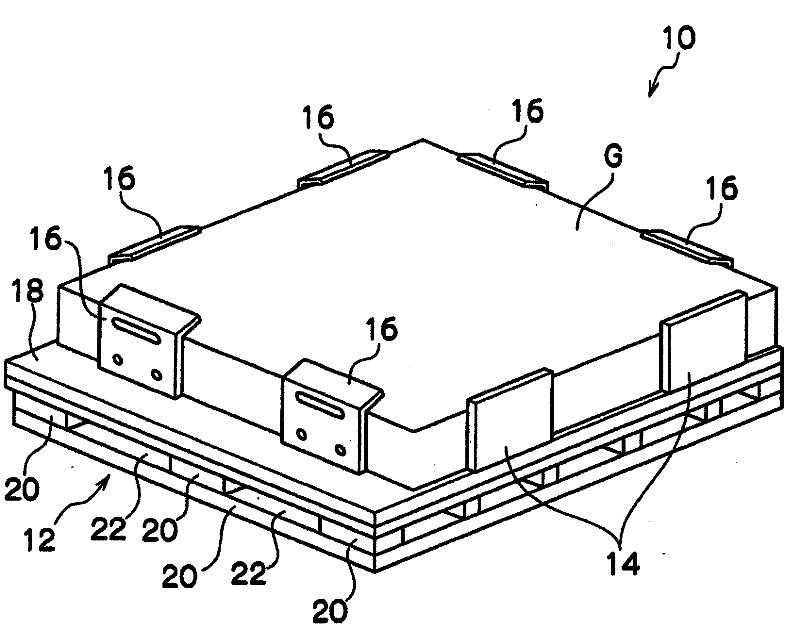

[0036] figure 1 It is an overall perspective view showing an example of the storage tray 10 stacked on the plate-shaped object stacking device of the embodiment.

[0037] On the storage tray 10 shown in this figure, a plurality of sheets, for example, 80 to 150 pieces are stacked and stored horizontally with a rectangular composite paper (not shown) having a size larger than the glass plate G between each other. A rectangular glass plate G. The glass plate G shown in the embodiment is a mother glass substrate with vertical and horizontal dimensions of about 3200×3000 (mm) used in a flat panel display (FPD), and the thickness of the plate is 1 mm or less. In addition, the size of glass plate G is not limited to this, As mentioned later, the plate-shaped body stacking apparatus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com