Handle shaft assemblies for bottom loading couplers

A handle shaft and coupling technology, applied in couplings, valve devices, transportation and packaging, etc., can solve problems such as affecting the operation of the bottom loading coupling, damage to the bottom loading coupling, difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

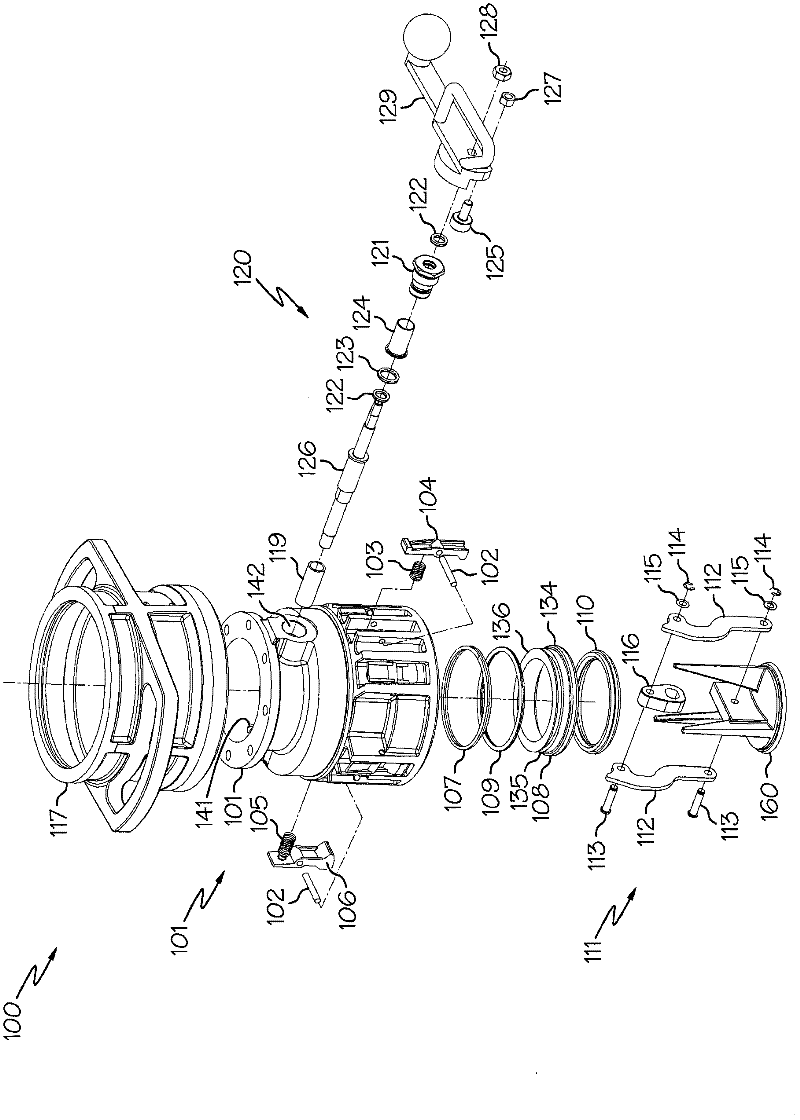

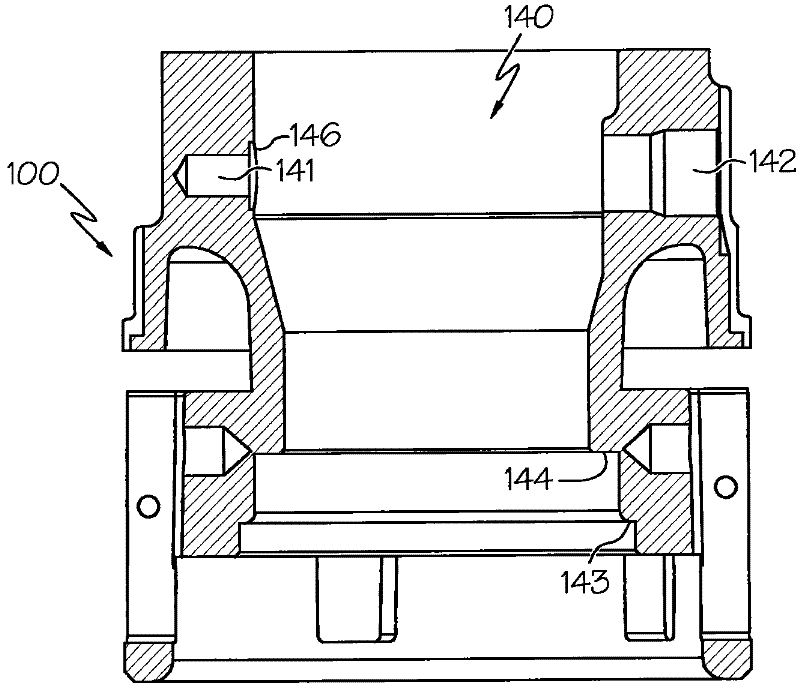

[0021] figure 1 An exploded view of the bottom loading coupling is shown generally. The bottom loading coupling generally includes a body having a poppet valve assembly disposed therein. The poppet valve assembly is actuated by the handle shaft assembly which includes a tube spacer, handle shaft, stuffing box, sleeve bearings, cam followers, and operating handle. The bottom loading coupling, handle shaft assembly and stuffing box will be described in more detail herein with specific reference to the accompanying drawings.

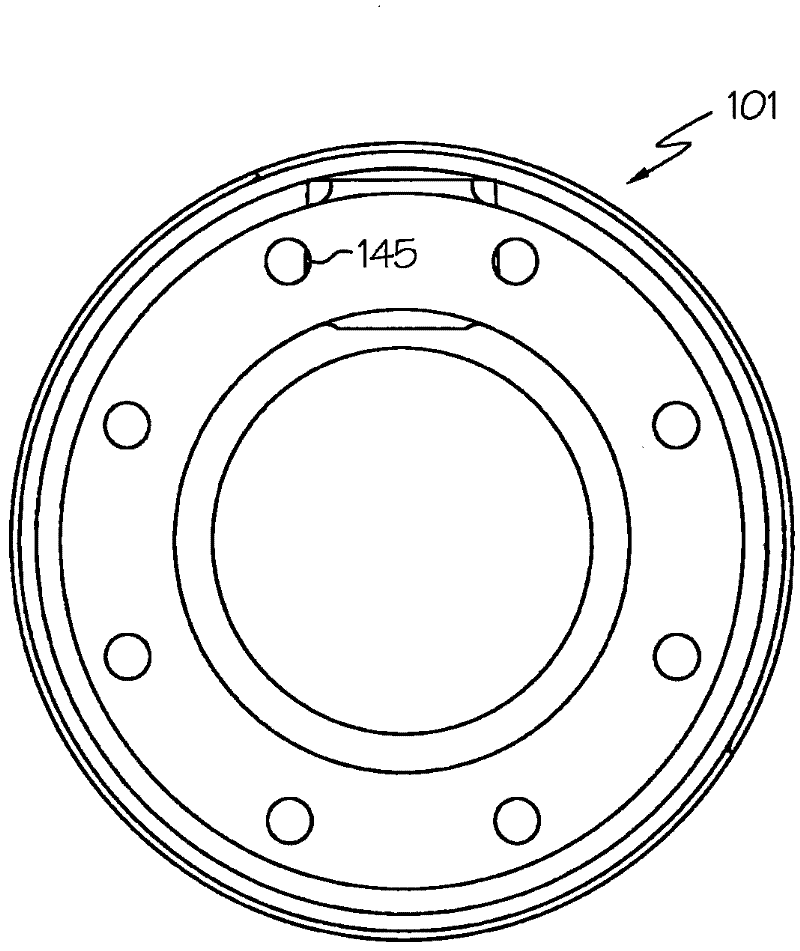

[0022] refer to figure 1 , an exploded view of one embodiment of a bottom loading coupling 100 is shown. The bottom loading coupling 100 generally includes a coupling body 101 having a poppet valve assembly 111 disposed within a cylindrical cavity formed by the body 101 . Although the exemplary body 101 shown in the figures is substantially cylindrical, it should be understood that the body 101 may have other shapes and configurations. Outer coupling s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com