Shell-and-tube heat exchanger with un-notched traverse baffles

A technology of shell-and-tube heat exchangers and baffles, which is applied in the direction of indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., to improve heat exchange efficiency, reduce heat transfer "dead zones, and reduce The effect of pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

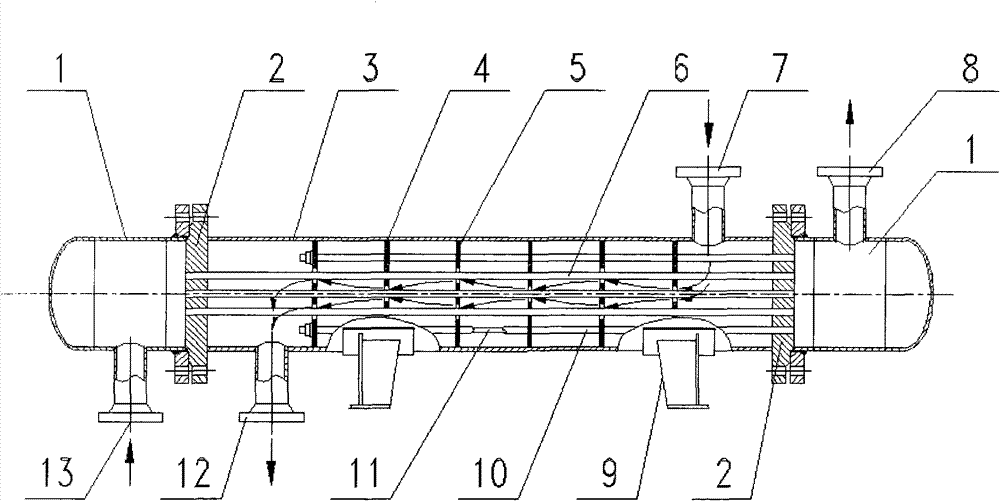

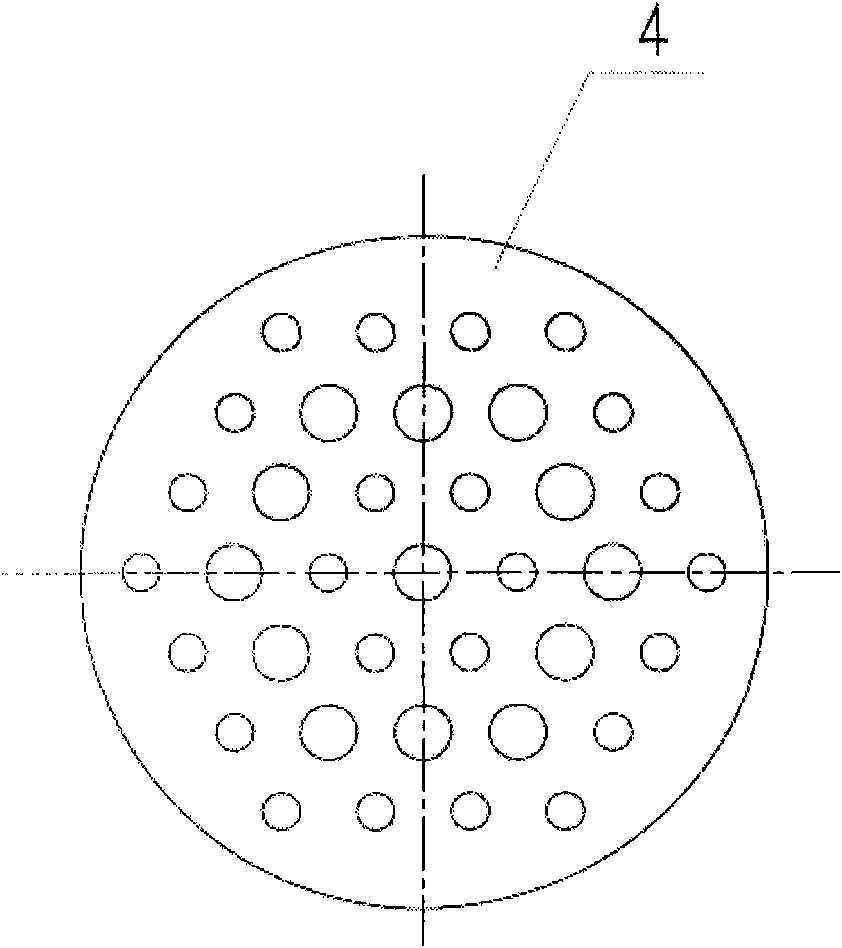

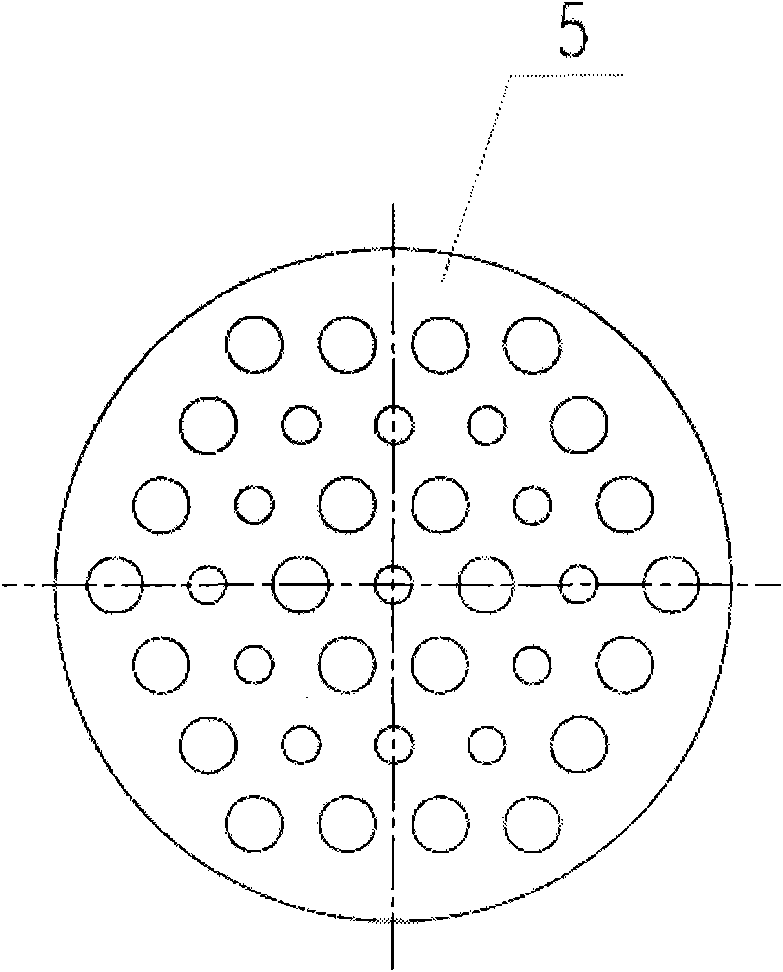

[0026]The shell-and-tube heat exchanger with no gap baffles of the present invention can be found in figure 1 , including: a cylinder 3 placed on the saddle 9, shell-side fluid inlet 7 and shell-side fluid outlet 12 are respectively opened on both ends of the cylinder, fixed tube sheets 2 are arranged at both ends of the cylinder, and the outer sides of the two tube sheets are respectively Two tube boxes 1 are connected, and the two tube boxes are respectively opened with a tube-side fluid inlet 13 and an outlet 8. There is a heat exchange tube bundle 6 in the cylinder, and the tube bundle passes through a set of tube holes of baffles 4 and 5 without gaps. Parallel fixed between the tube plates, the baffles are uniformly fixed in the axial direction by the tie rods 11 and the spacer tubes 10 . The distribution of the tube holes on the baffle is triangular. The tube-side fluid of the heat exchange medium is water, and the inlet temperature is 20°C. The shell-side fluid is C6 oi...

Embodiment 3

[0034] For the non-notched baffle shell and tube heat exchanger of the present invention, refer to Figure 7 , including: a cylinder body 5 placed on the saddle 10, shell side fluid inlet 4 and shell side fluid outlet 9 respectively opened at both ends of the cylinder body 5, one end of the cylinder body 5 is connected to the fixed tube sheet 3 through a flange, and the tube sheet The outer side is connected to the tube box 1 (left tube box). The tube box 1 is respectively provided with a tube-side fluid inlet 13 and an outlet 2. There are U-shaped tube bundles 8 and baffles 6 and 7 in the cylinder body 5. The baffles are perpendicular to the tubes. The shaft is fixed parallel and evenly distributed along the axial direction by the tie rod 12 and the spacer tube 11. The tie rod 12 is fixed on the tube plate 3, and the baffles 6 and 7 are non-notch baffles, and each baffle has different sizes. Two kinds of circular tube holes, the distribution of the circular tube holes of any ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com