Seat adjusting apparatus for vehicle

A technology for adjusting equipment and vehicles, which can be applied to vehicle seats, special positions of vehicles, movable seats, etc., and can solve problems such as deformation of long holes or connecting pins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

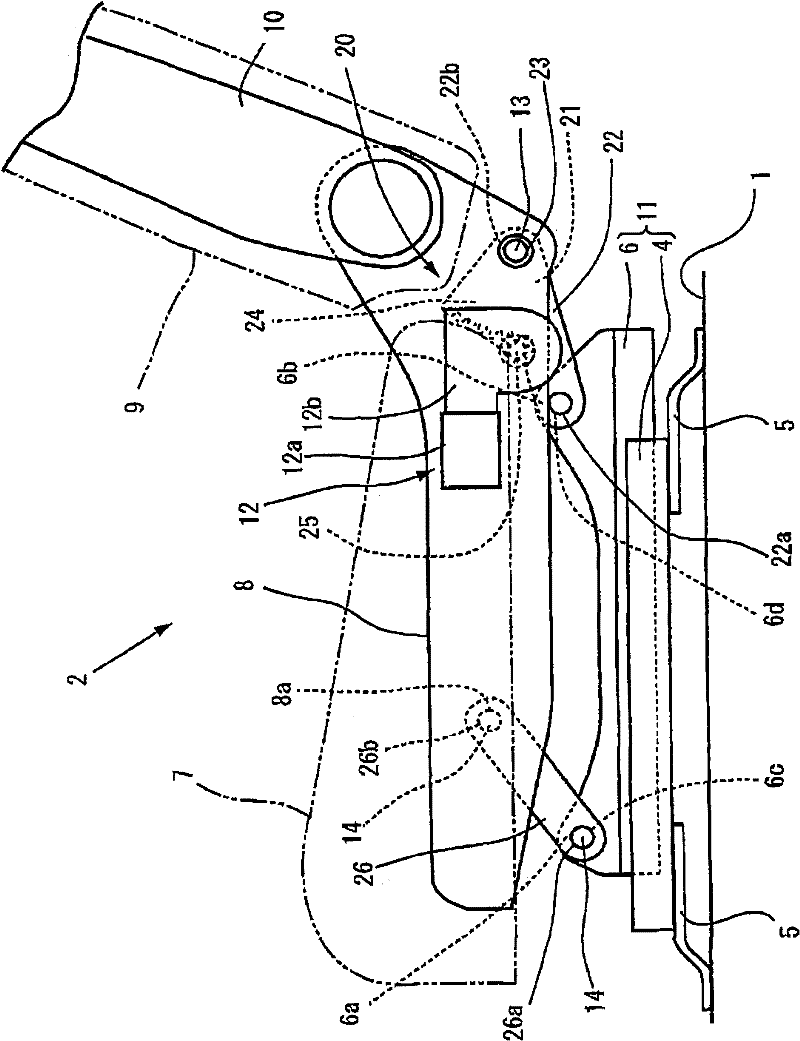

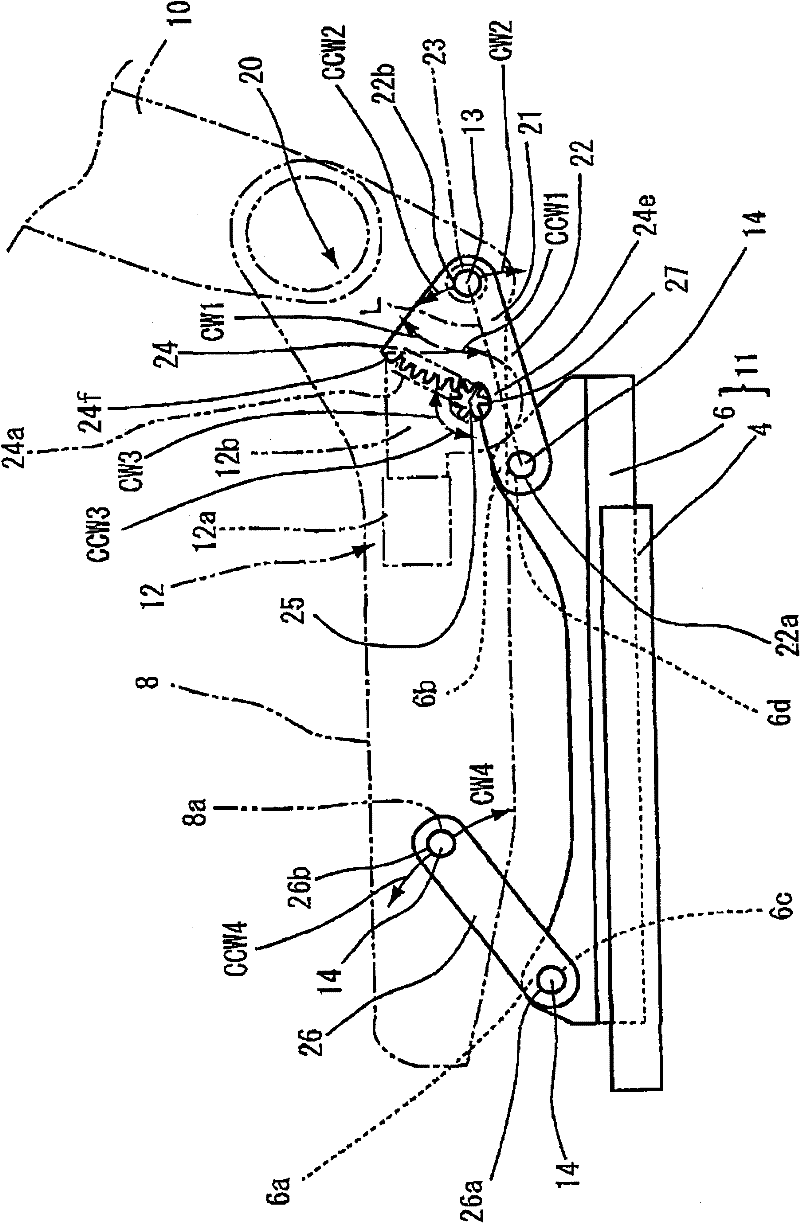

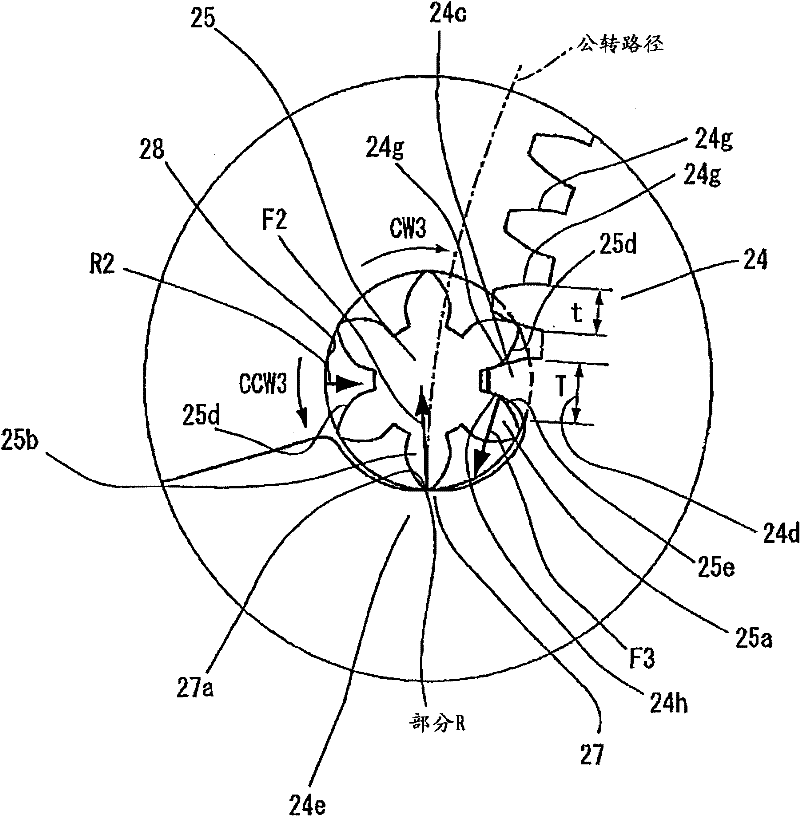

[0031] A first embodiment of the seat lifting apparatus 20 of the present disclosure will be described. in the attached figure 1 Among them, the seat lifting device 20 is mounted on a seat device 2 for a vehicle as a seat adjusting device for a vehicle (hereinafter referred to as a seat) for adjusting the height of a seat cushion on which a vehicle occupant sits. chair adjustment device). in the attached figure 2 , the seat cushion is at rest in the fully lowered position. As used herein, the words "rear-rear direction", "lateral direction" and "vertical direction (up-down direction)" and their derivatives refer to directions relative to the vehicle.

[0032] as attached figure 1 As shown in , a seat apparatus 2 for a vehicle (hereinafter referred to as seat apparatus 2) includes a seat rail 11, a seat lifter 20, a lower arm constituting a part of a seat cushion 7 and the seat lifter 20 8, and the upper arm 10 constituting the seat back 9, the seat slide rail 11 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com