Cylinder control valve for down-the-hole drill

A technology of cylinder control and down-the-hole drilling, which is applied in the direction of valve details, safety valves, balance valves, etc., can solve the problems of pulling the handle, inaccurate positioning, and affecting the flexibility of valve core rotation and operation, so as to ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and examples.

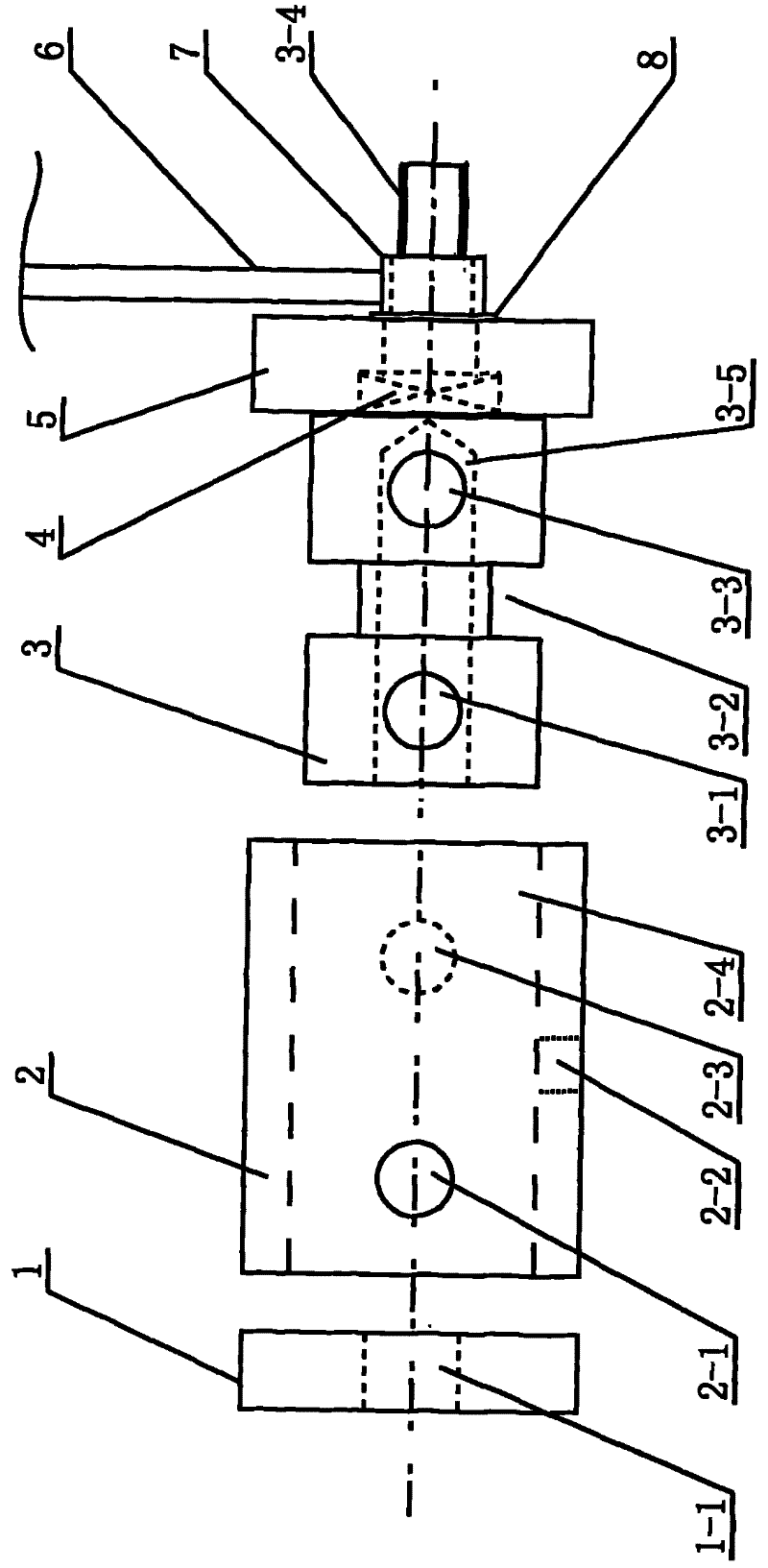

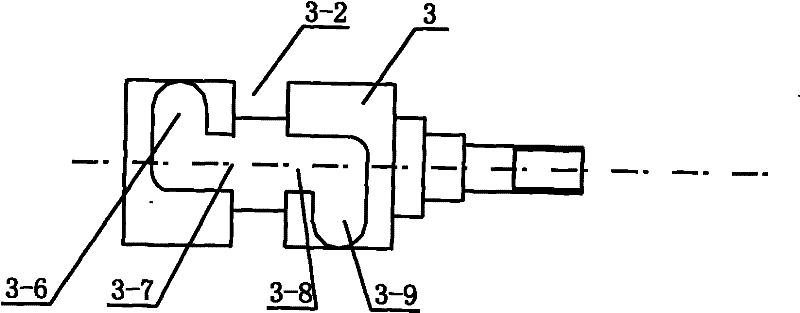

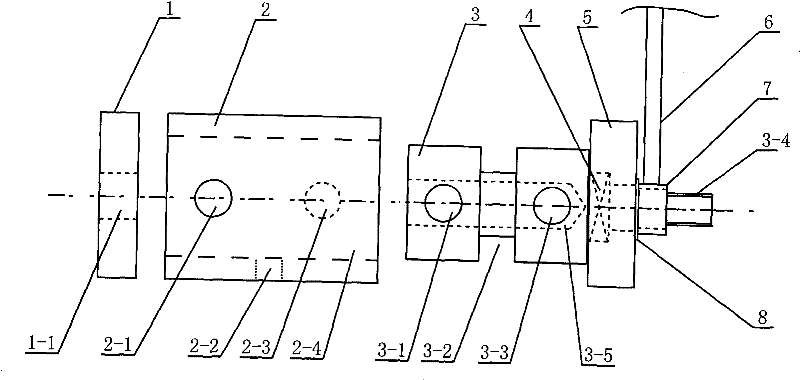

[0025] Such as figure 1 As shown, this embodiment includes a valve body 2 with a valve body center hole 2-4, a valve core 3 tightly fitted and rotatably installed in the valve body center hole 2-4, and the valve core 3 has an open end The spool center hole 3-5 that the other end is closed.

[0026] It also includes a valve seat 1 connected to the inner end of the valve body 2 and a valve cover 5 connected to the outer end of the valve body 2 . The outer end of the valve core 3 passes through the valve cover 5 and is connected with a handle seat 7 with a handle 6 . The outermost end of the spool 3 is a threaded section 3-4 for installing an adjusting nut. A thrust roller bearing 4 is installed in the valve cover 5 , and the inner end surface of the thrust roller bearing 4 leans against the valve core 3 . A damping gasket 8 is also installed on the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com