System for using LNG (Liquefied Natural Gas) in air conditioner

A technology of air conditioning and circulation system, which is applied in the field of cold energy utilization of liquefied natural gas (LNG for short), and can solve problems such as energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

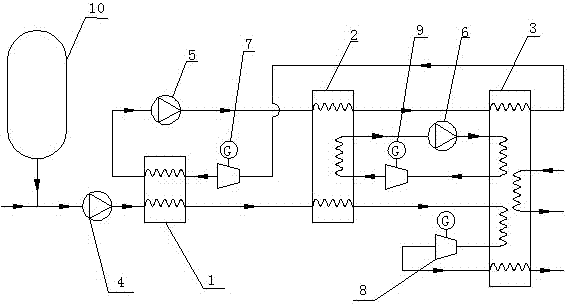

[0023] like figure 1 As shown, the liquefied natural gas in the cryogenic storage tank 10 or from other sources is first pressurized by the first LNG pump 4, then passes through the first heat exchanger 1, the second heat exchanger 2 and the third heat exchanger 3 in sequence, and then enters the first heat exchanger. The second expansion generator 8 generates power, and the natural gas coming out of the second expansion generator 8 passes through the third heat exchanger 3 to further recover its heat and improve the utilization rate of the cooling capacity of the liquefied natural gas. The medium-temperature refrigerant vapor is condensed into a liquid by the low-temperature refrigerant and natural gas in the second heat exchanger 2, then pressurized by the medium-temperature refrigerant pump 6, and exchanges heat with the brine for air conditioning in the third heat exchanger 3, It is heated into steam, then enters the third expansion generator 9 to expand and generate power...

Embodiment 2

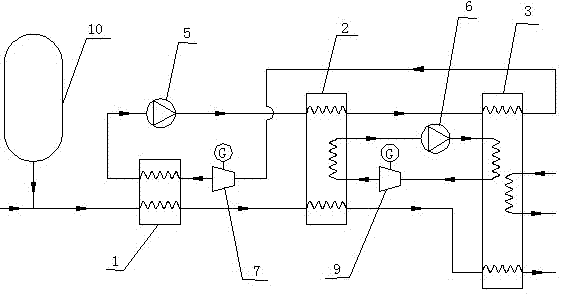

[0025] like figure 2 As shown, the liquefied natural gas in the cryogenic storage tank 10 or other sources directly enters the first heat exchanger 1, the second heat exchanger 2 and the third heat exchanger 3, and then directly enters the pipeline network for gas supply, canceling the first LNG Pump 4 and the second expansion generator 8, the medium-temperature refrigerant vapor is condensed into liquid by the low-temperature refrigerant and natural gas in the second heat exchanger 2, and then pressurized by the medium-temperature refrigerant pump 6 to enter the third heat exchanger 3 Exchange heat with the refrigerant used for air conditioning, be heated into steam, then enter the third expansion generator 9 to expand and generate power, and finally return to the second heat exchanger 2 to complete the closed cycle of medium-temperature refrigerant; low-temperature refrigerant steam In the first heat exchanger 1, the cooling capacity of liquefied natural gas is condensed in...

Embodiment 3

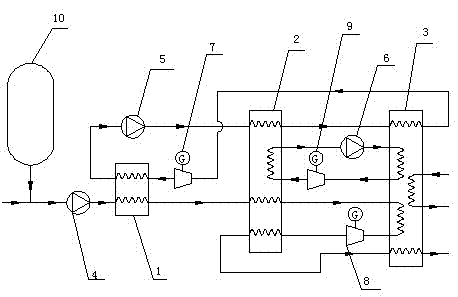

[0027] like image 3 As shown, the liquefied natural gas in the cryogenic storage tank 10 or from other sources is first pressurized by the first LNG pump 4, then passes through the first heat exchanger 1, the second heat exchanger 2 and the third heat exchanger 3 in sequence, and then enters the first heat exchanger. The second expansion generator 8 generates power, and the natural gas from the second expansion generator 8 passes through the second heat exchanger 2 and the third heat exchanger 3 to further recover its heat and improve the utilization rate of the cooling capacity of the liquefied natural gas. The medium-temperature refrigerant vapor is condensed into a liquid by the low-temperature refrigerant and natural gas in the second heat exchanger 2, then pressurized by the medium-temperature refrigerant pump 6, and exchanges heat with the brine for air conditioning in the third heat exchanger 3, It is heated into steam, then enters the third expansion generator 9 to ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com