Switch, particularly power switch

A power switch and switch technology, applied in the field of power switches, can solve problems such as load damage and switch damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

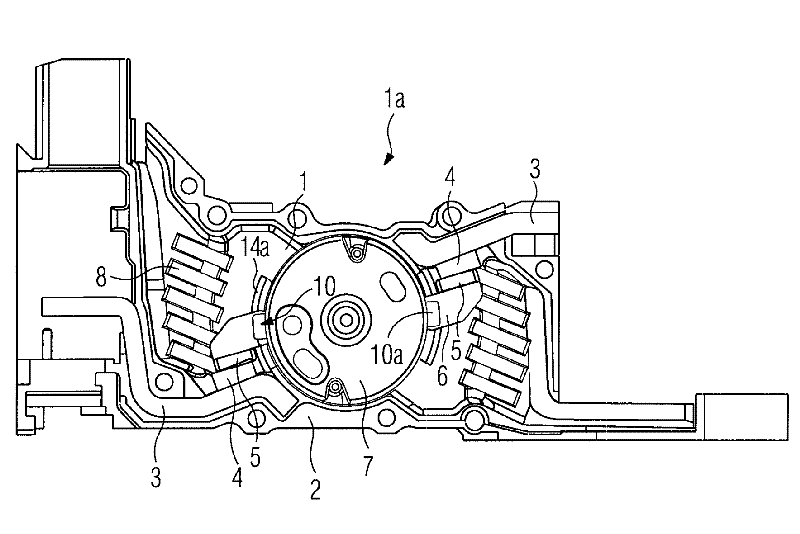

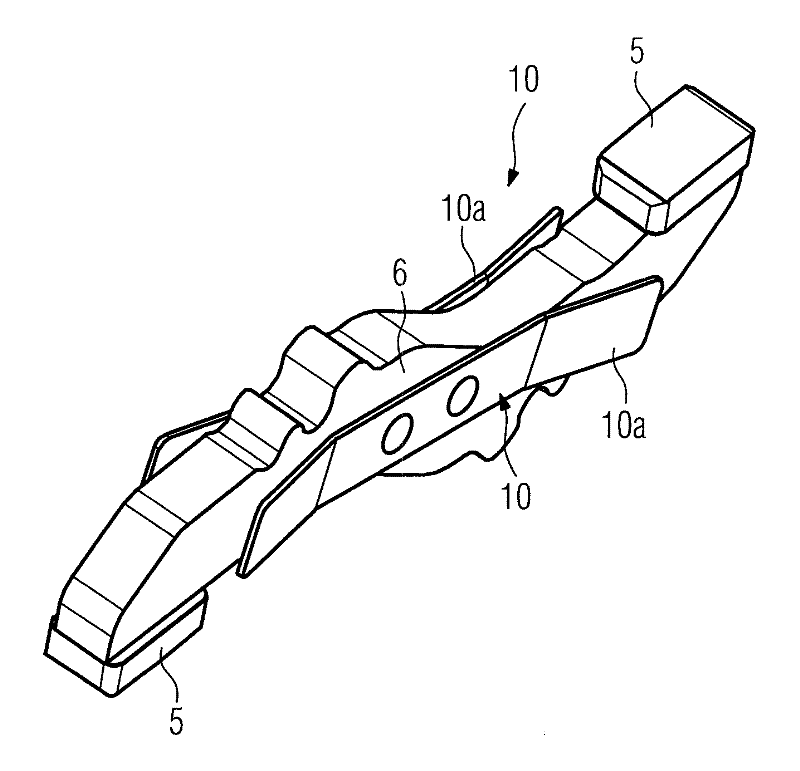

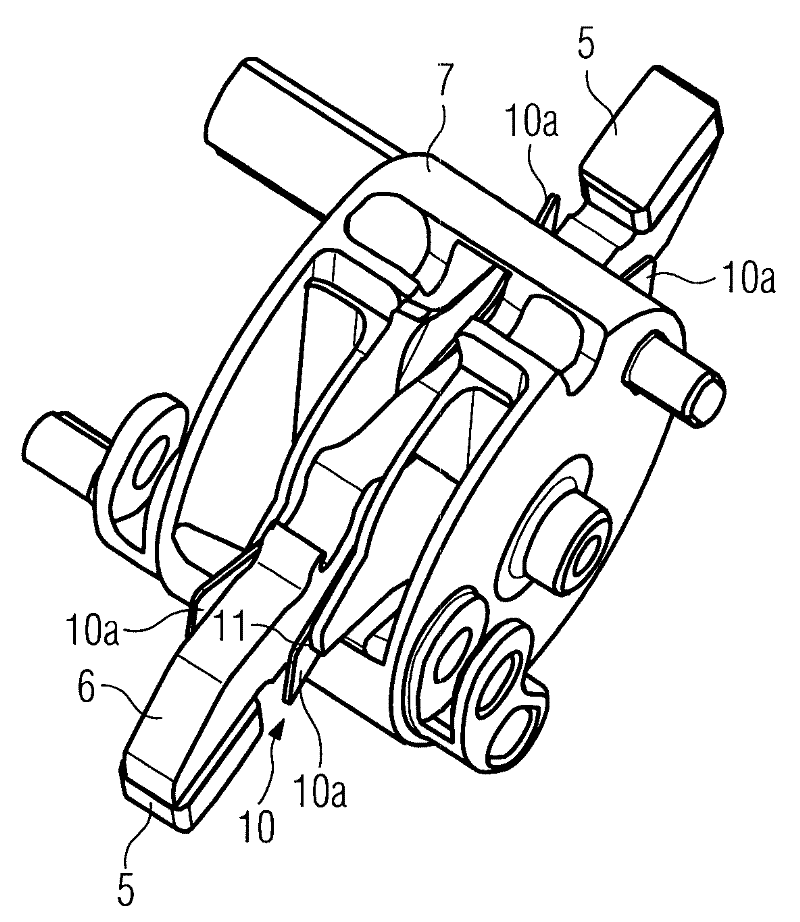

[0018] figure 1 A pole box 1 of a multipole power switch is shown, referred to below as a switch. The pole box 1 forms a housing 1a and consists of two half-shells 2, in figure 1 One of the two half-shells was removed. The pole box 1 has two connection terminals 3 , on the inner ends of which a fixed contact piece 4 is arranged in each case. On the contact piece 4 rests an associated contact piece 5 which is arranged at the free end of a contact arm 6 which is designed here as a double-armed lever. In addition, a rotor 7 in the form of a switching shaft section is rotatably mounted in the pole box 1 , in which rotor the contact arm 6 is in turn mounted in a pivotable manner. The two axes of rotation coincide here. The contact arm 6 can be deflected between an on position and an off position; figure 1 The contact arm 6 is in its on position in which the switch is switched on. When the switch is connected, current flows from the line-side terminal 3 via the two contact pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com