Drive unit

A technology of drive unit and rotary joint, which is applied in the direction of passing components, rolling contact bearings, and rotating bearings. It can solve the problems of support and shaft clearance, unfavorable consumption of inherent lubricating materials, and increased temperature, and achieve small concentricity deviation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

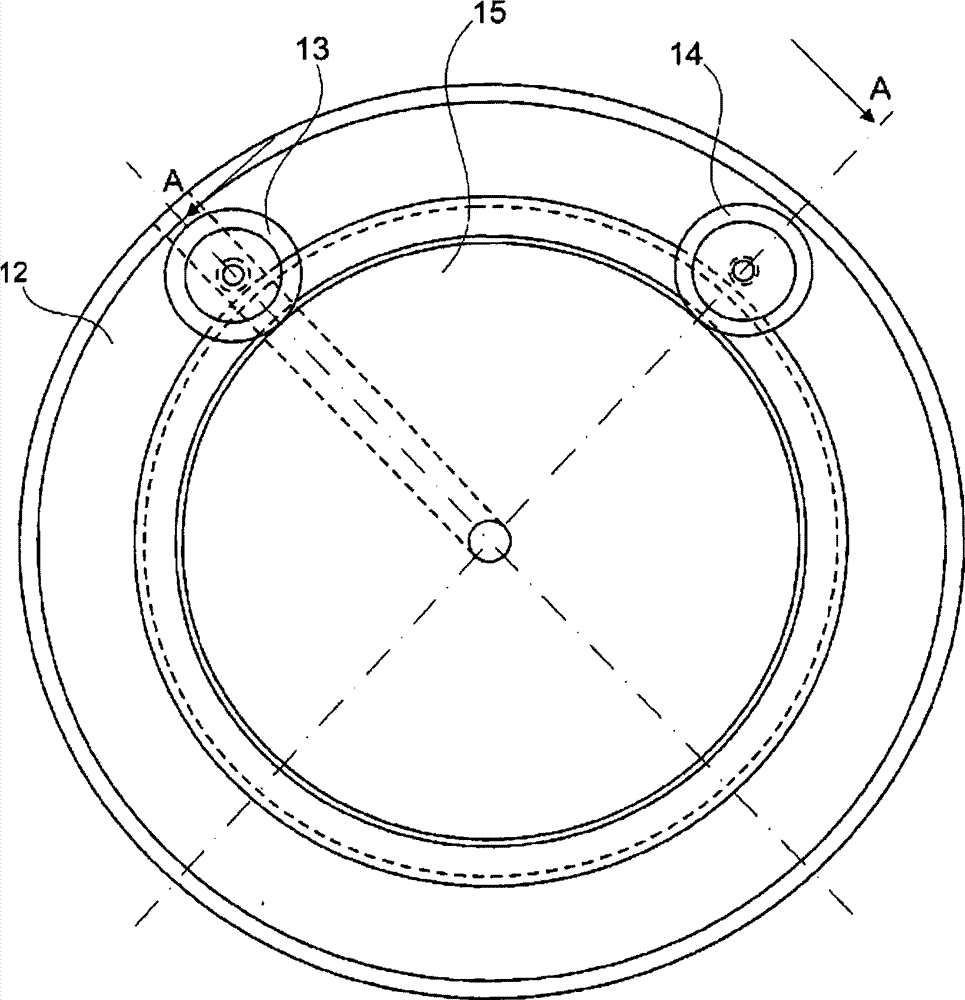

[0031] In the first embodiment of the present invention ( image 3 ,4), the swivel joint has a swivel joint part 12 fixed at the device, which is supported by two pairs of supporting rollers 13, 14 that are mounted on the swivel joint part 12 at the end side to rotate relative to the swivel joint part 15. The two pairs of support rollers 13, 14 are arranged at a suitable angle to each other. The position of the support rollers 13 , 14 relative to the housing part 16 of the swivel joint part 15 is determined via the shaft or via lateral fastening means. Correspondingly, an annular bearing 19 is located between the roller shaft 17 and the housing part 18 .

[0032]The support rollers 13 , 14 lie outside an annular cavity 22 which surrounds the swivel joint part 15 , which is sealed by seals 20 , 21 . A medium supply line 23 leading to the cavity 22 is installed in the housing part 16 . From there, the medium for lubrication and / or cooling is conveyed into radially extending c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com