Automatic spraying valve

A spray valve and automatic technology, which is applied in safety devices, mining equipment, earthwork drilling and mining, etc., can solve the problems of spray water and hydraulic emulsion leakage, leaking, leakage, and liquid leakage, so that it is not easy to escape, drip, leakage, and liquid leakage. Good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

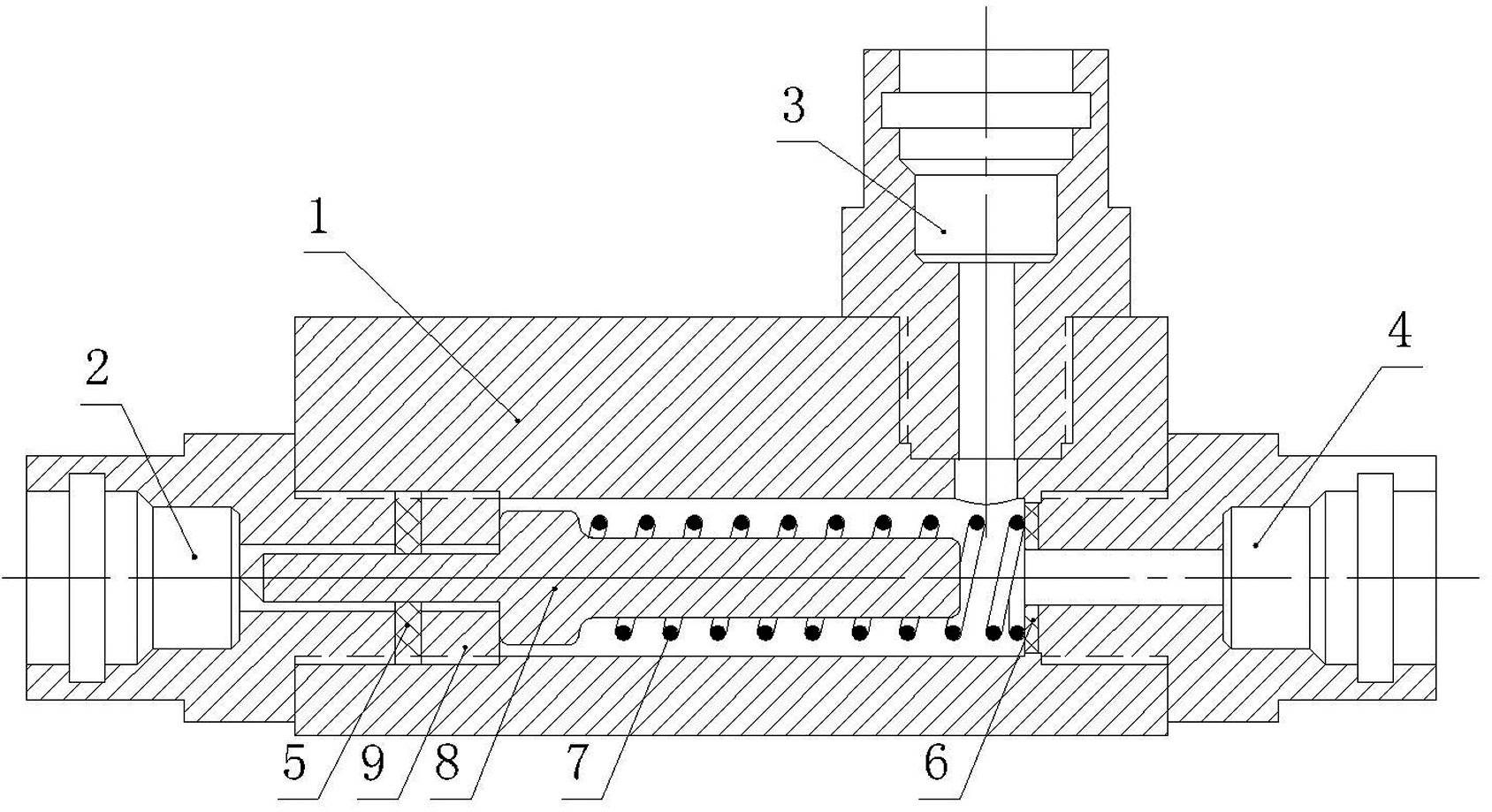

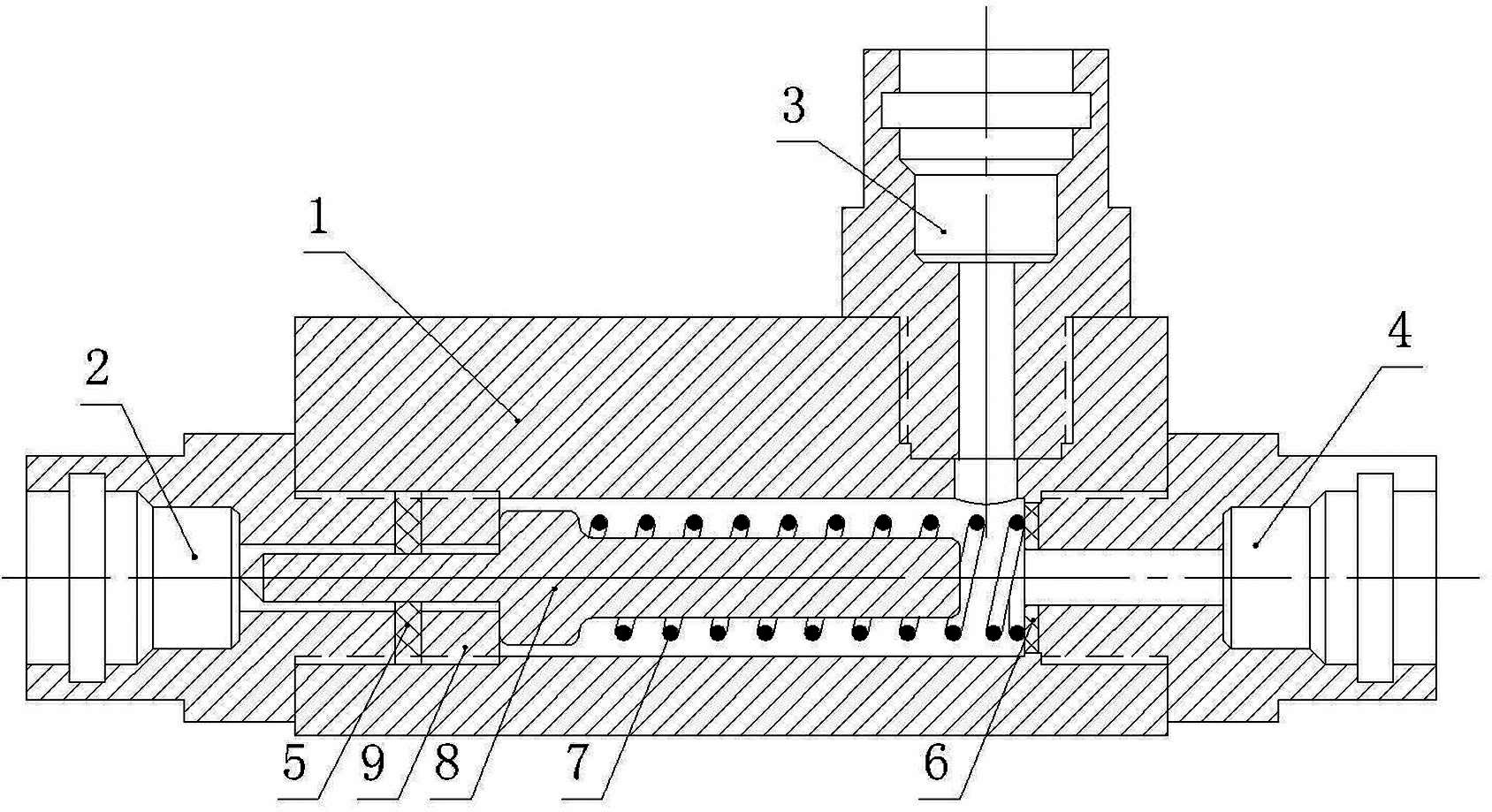

[0007] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but does not constitute any limitation to the present invention. figure 1 As shown, the present invention includes a valve body 1 and a valve core. The center of the valve body 1 is provided with a conventional valve hole, and the two ends of the valve hole are respectively screwed with a joint seat 2 and a joint seat 2 4. The valve body 1 The side is screwed with joint seat three 3, and this joint seat three 3 communicates with the valve hole. The valve hole is a stepped hole, and the back ring 9 is packed into the bottom of the hole with a larger diameter in the stepped hole, then the sealing ring-5 is packed into, and finally screwed into the joint seat-2. The purpose of setting the retaining ring 9 is to position the sealing ring one 5 and the valve stem 8, improve the strength of the sealing ring one 5 and apply a force to the spring 7 at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com