Electromagnetic speed-regulation driving system

A drive system, electromagnetic speed regulation technology, applied in the direction of control system, electromechanical transmission device, electrical components, etc., can solve the problems of increased design cost, complex design, inevitable permanent magnet demagnetization, etc., to reduce loop reluctance, The effect of reducing the inter-axis error and simplifying the system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

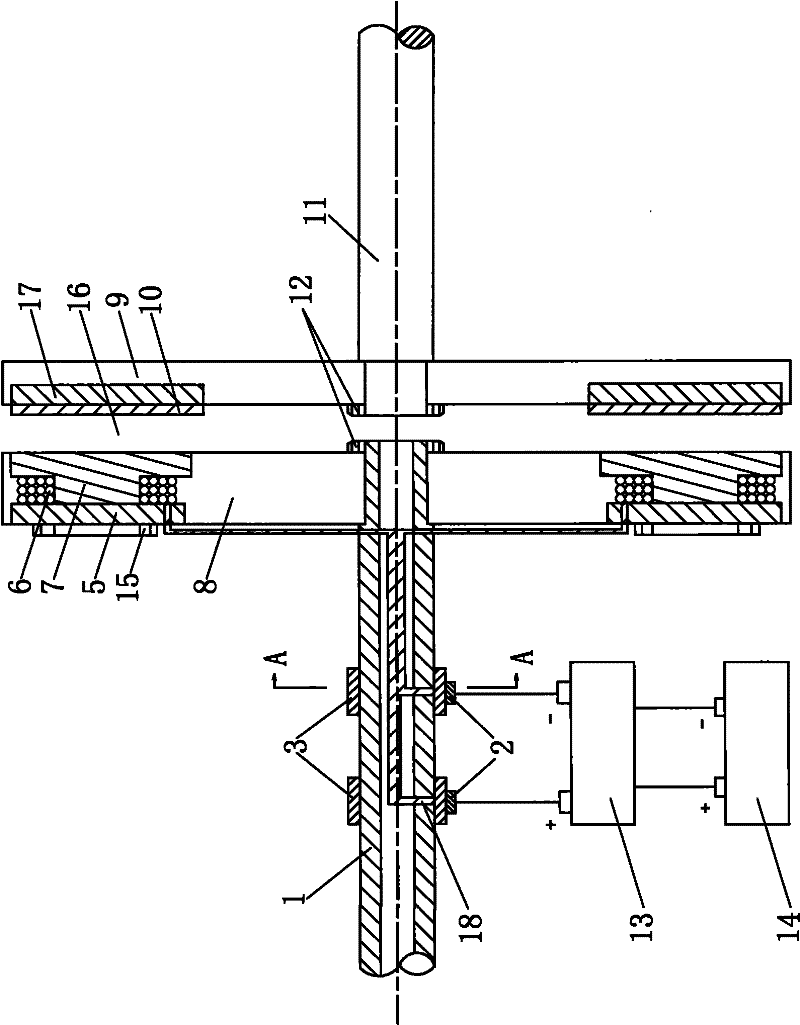

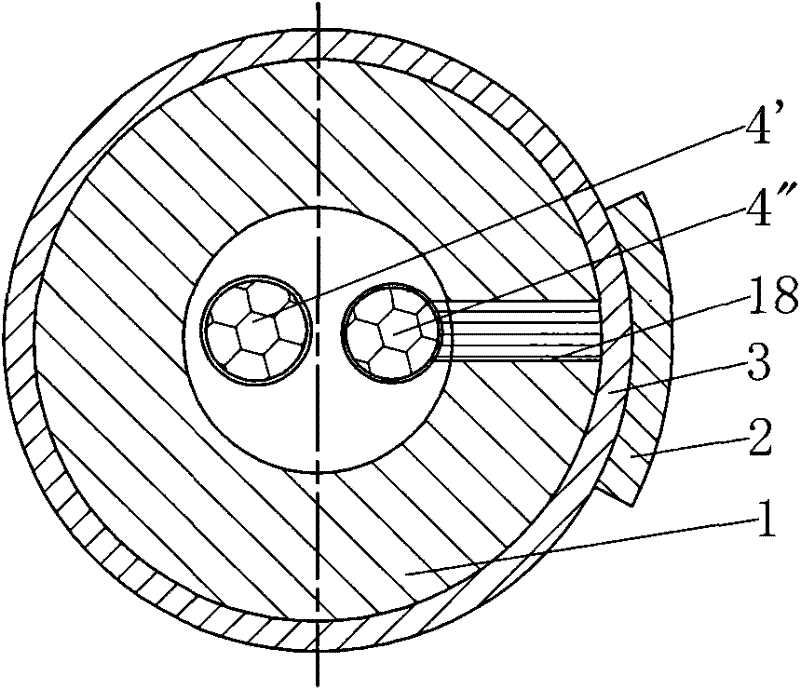

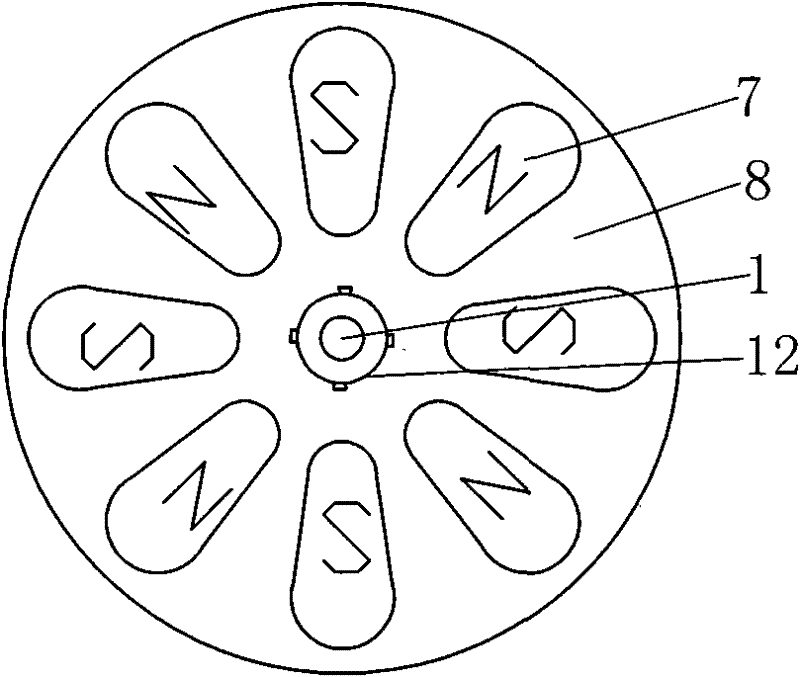

[0018] Embodiment 1: as figure 1 As shown, the present invention includes an input shaft 1 and an output shaft 11 arranged concentrically, an electric slip ring 3 sleeved on the input shaft 1, two brushes 2 close to the electric slip ring 3, and an electromagnetic rotor installed at the end of the input shaft 1 8. The conductor rotor 9, the current controller 13, and the power supply 14 installed on the end of the output shaft 11, the electromagnetic rotor 8 is installed with the iron core 7 around the coil 6 along the circumference, and the coil 6 and the two electric slip rings 3 respectively pass through the wire 4' , 4" connection, the two brushes 2 on the two electric slip rings 3 are connected to the positive and negative poles of the power supply 14 through the current controller 13, the conductive ring 10 is provided on the conductor rotor 9, and the end faces of the conductive ring 10 and the electromagnetic rotor The end faces of the iron core 7 of 8 are arranged cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com