Glow plug and method for producing the same

A technology for glow plugs and power supply lines, applied in combustion methods, lighting and heating equipment, combustion ignition, etc., can solve the problems of indirect loss, breakage, etc., and achieve the effect of reducing the risk of damage, simple design, and high-quality brazing connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

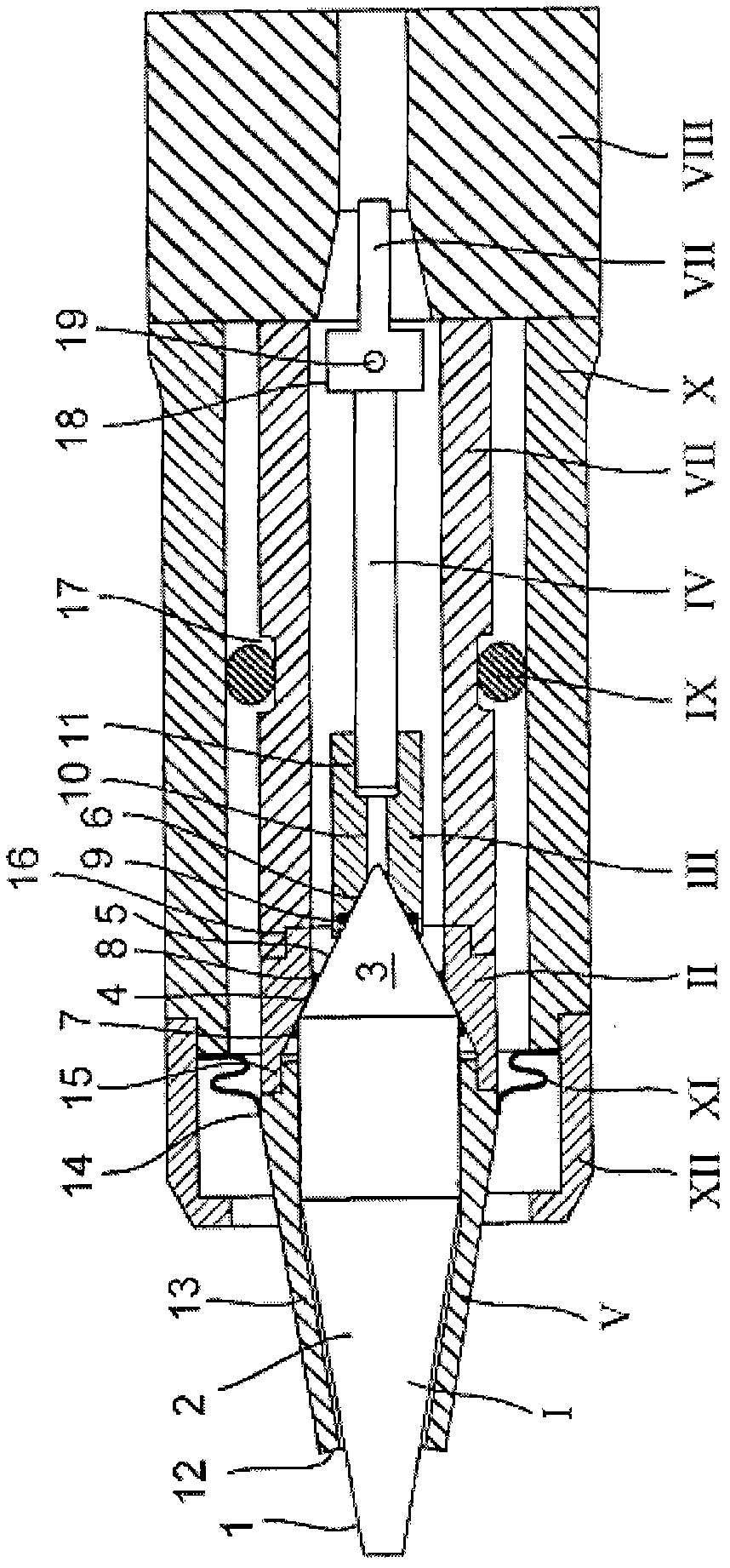

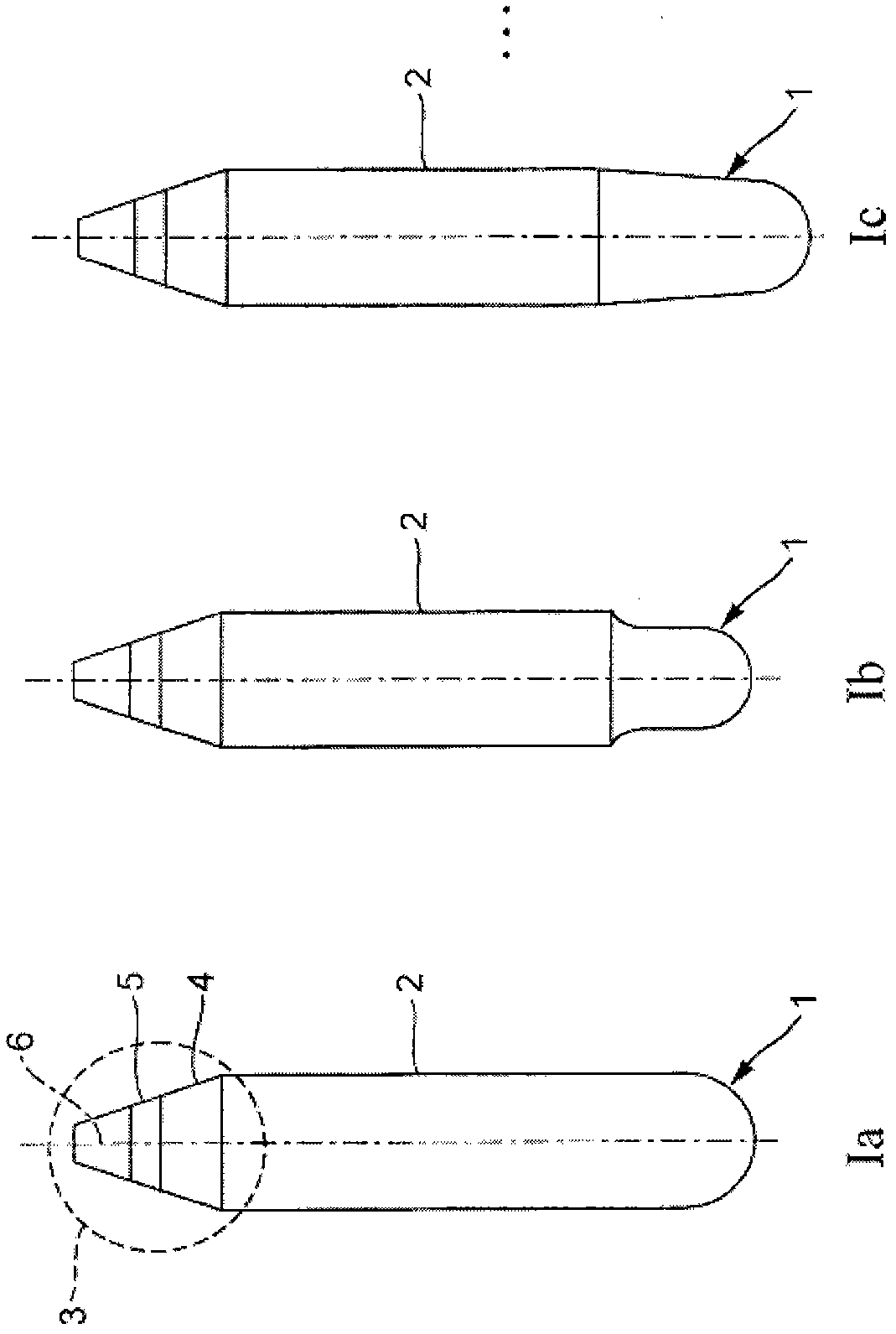

[0069] figure 1 An exemplary embodiment of a glow plug according to the invention is shown with a ceramic glow pin I protruding from a housing consisting of an upper housing part X and a lower housing part X and surrounded by a sleeve V Part XII Composition. The heating pencil 1 has an inner conductor, an outer conductor and an insulator arranged between them. The glow pencil tapers toward its end, which is arranged in the housing, preferably conically. For electrical connection to the inner conductor of the glow pencil, this end is inserted into an inner rod contact III which is connected to the supply line IV and to which the glow pencil I is soldered.

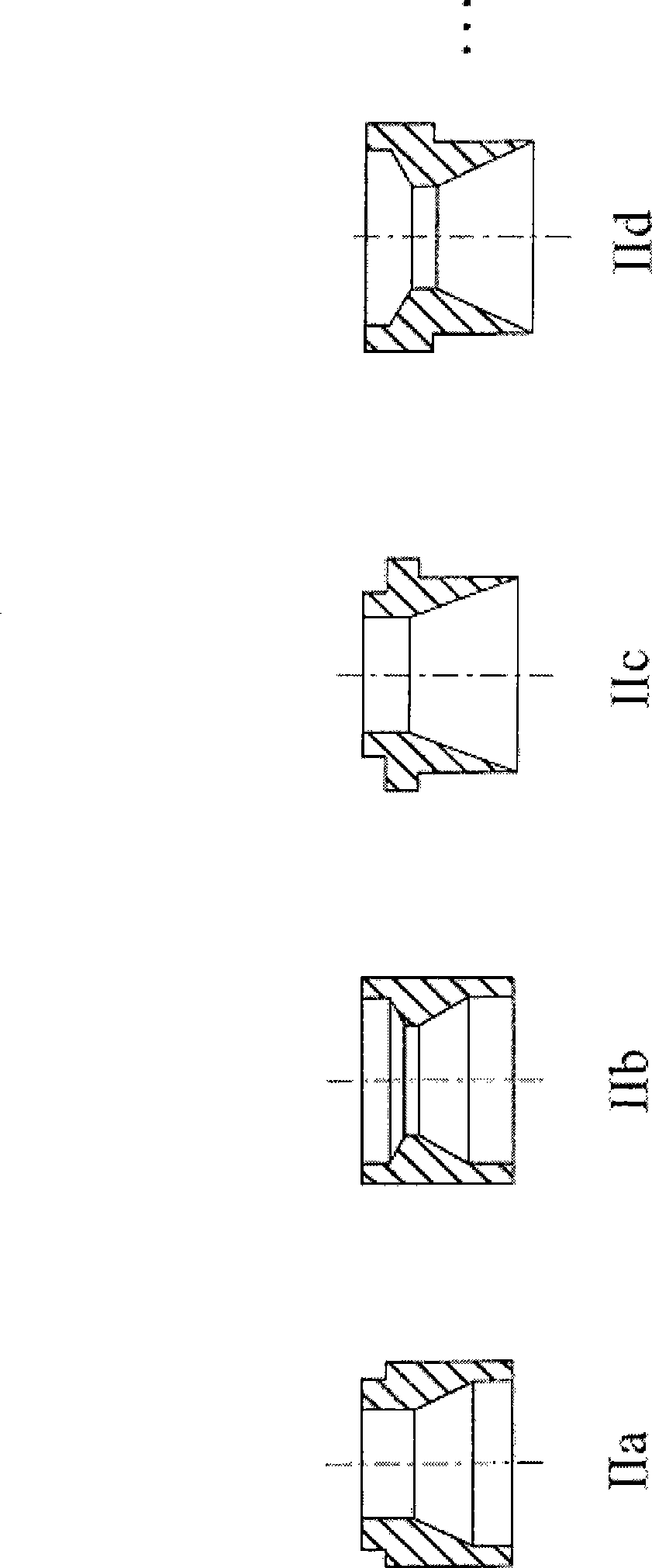

[0070] The outer conductor of the glow pencil is electrically connected via the contact element II, which is formed as a ring in the exemplary embodiment shown. The contact ring II is soldered to the glow pencil I, has a narrowed portion (which in the exemplary embodiment shown has a conical inner surface) and comprises a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com