Telescopic cleaning valve

A cleaning valve, telescopic technology, applied in the field of cleaning equipment, can solve problems such as inconvenience, and achieve the effect of avoiding damage or pollution, no hygienic dead angle, and ensuring hygienic dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

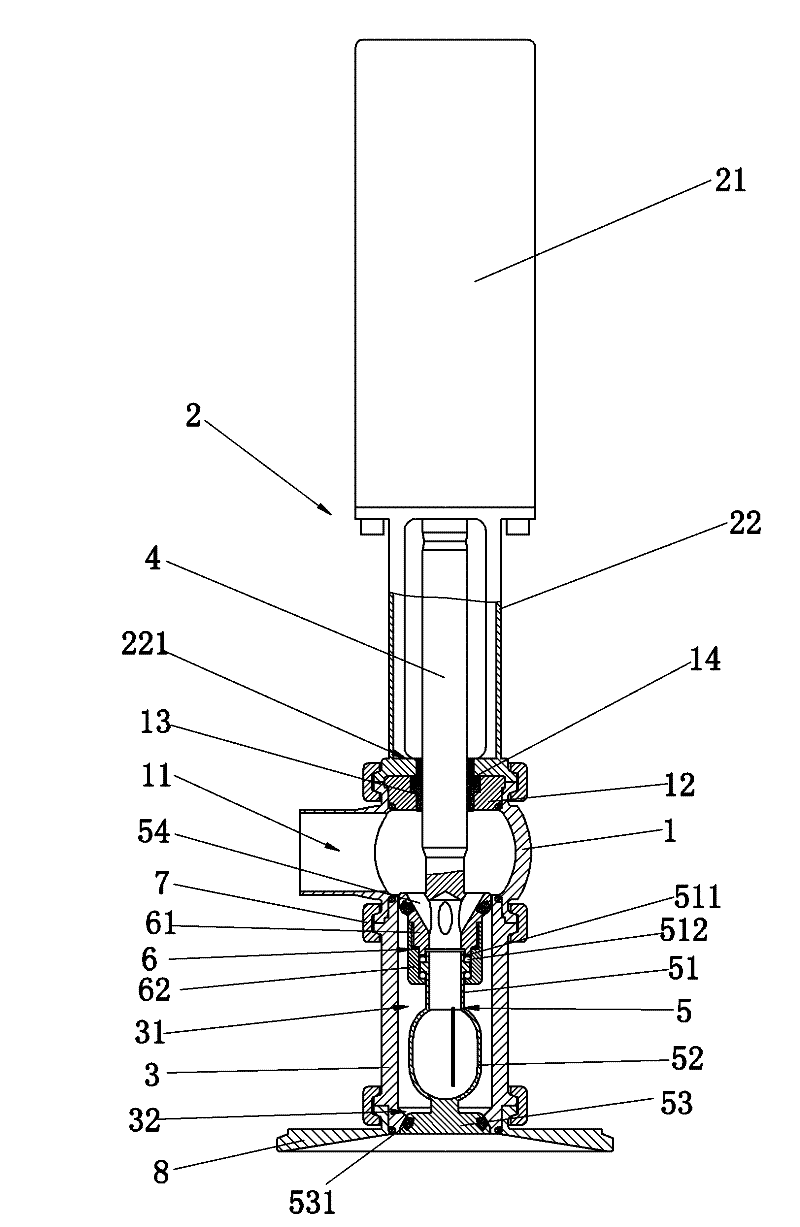

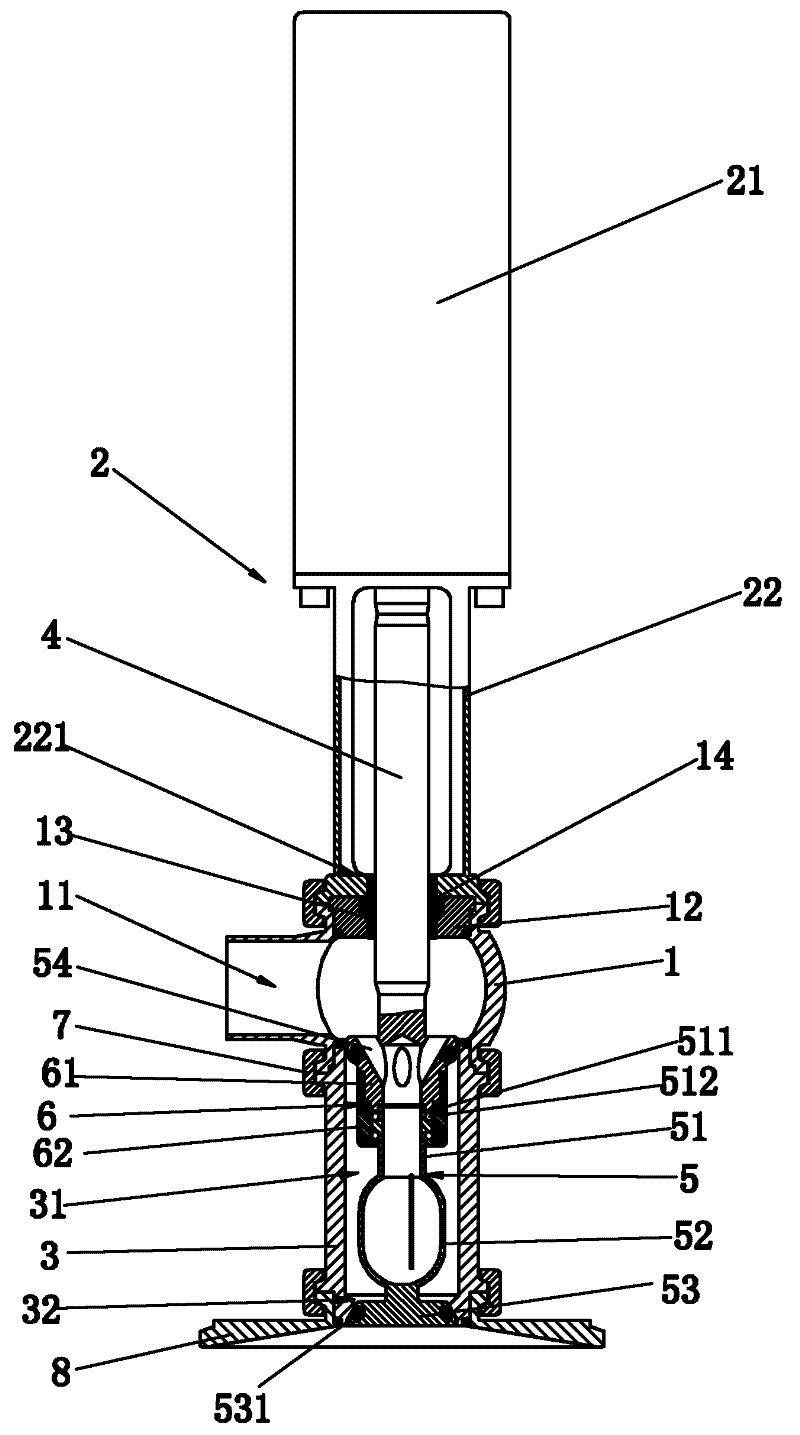

[0017] like figure 1 As shown, the embodiment of the present invention is specifically a telescopic cleaning valve, which includes a valve body 1 and a cleaning ball 5 arranged in the valve body 1. One side of the valve body 1 is provided with a cleaning liquid inlet 11, and the top of the valve body 1 An actuator 2 is provided, and the actuator 2 includes an execution system 21 and a bracket 22. The bracket 22 is set in cooperation with the valve body 1, and the joint is sealed. A valve stem 4 is arranged above the cleaning ball 5, and one end of the valve stem 4 is connected to the cleaning ball 5. Fixed, the cleaning ball 5 can rotate relative to the valve stem 4, the other end of the valve stem 4 extends through the bracket 22 and is fixed on the actuator 2, the valve stem 4 can do telescopic movement under the drive of the actuator 2, the bottom of the valve body 1 A cavity 31 is provided for placing the cleaning ball 5 . A boss 221 is provided below the bracket 22, a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com