Lifting and pressing mechanism applied to wafer polishing equipment

A technology of pressurizing mechanism and lifting mechanism, which is used in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc. , the inertia is small, the effect of improving the pressure control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they are not intended to limit the present invention.

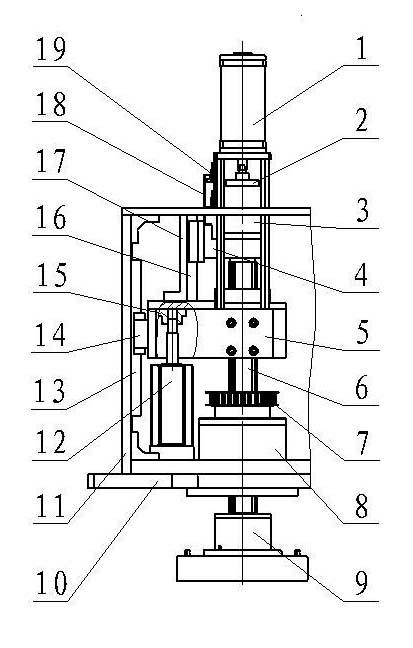

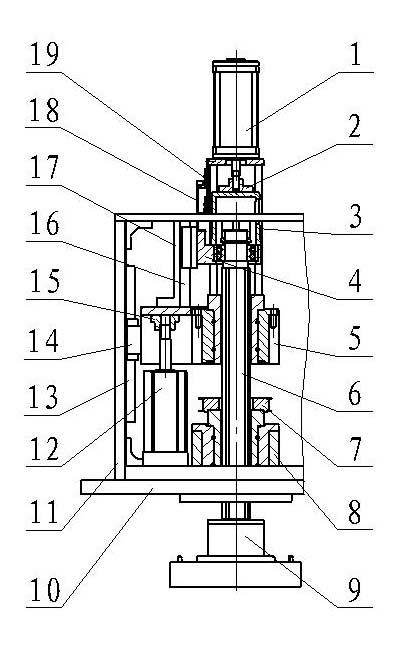

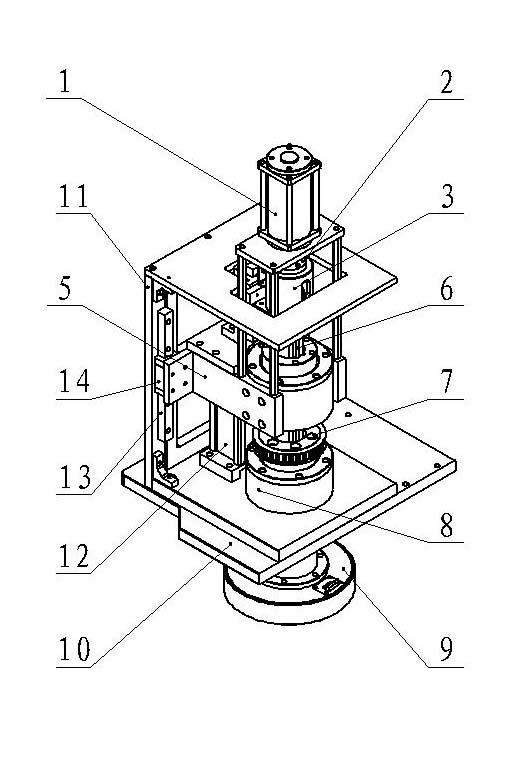

[0020] as attached figure 1 , 2 The embodiment of the present invention shown in . 3 includes a carrier 9, a frame, and a lifting mechanism and a pressurizing mechanism that are connected to the carrier 9 and can respectively control the pressurizing and lifting actions of the carrier 9, which are arranged on the frame.

[0021] The frame described in this embodiment is composed of a bottom plate 10, a side plate 11 and a top plate 20, and this frame plays the role of fixing, supporting and positioning reference for the whole mechanism.

[0022] The pressurizing mechanism includes a pressurizing cylinder 1, a spline shaft 6, and a connecting piece. The cylinder 1 is connected, the lower part of the spline shaft 6 passes through the frame bottom plate 10 to connect the carrier 9, the spline sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com