Optical cable ink writer

A printing machine and optical cable technology, which is applied in the field of optical cable printing machines, can solve the problems of messy and falling printing tapes, affecting printing quality, and printing work can not be carried out normally, so as to achieve the effect of keeping clean and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

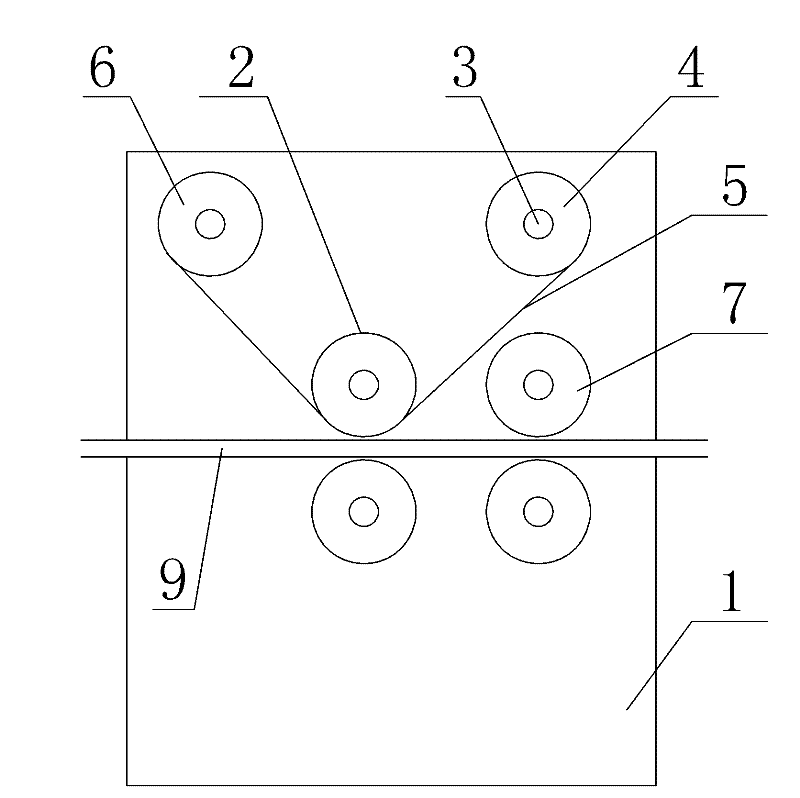

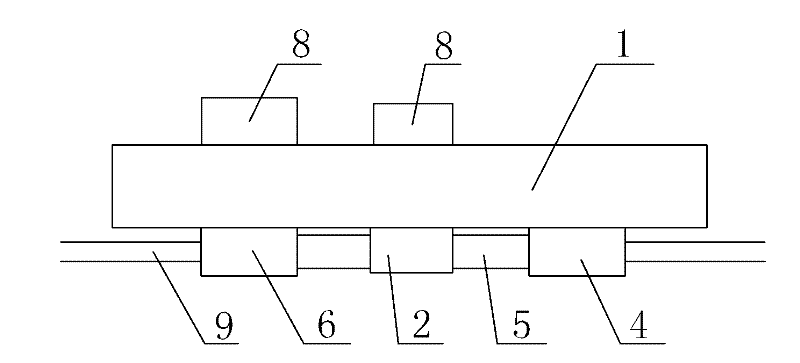

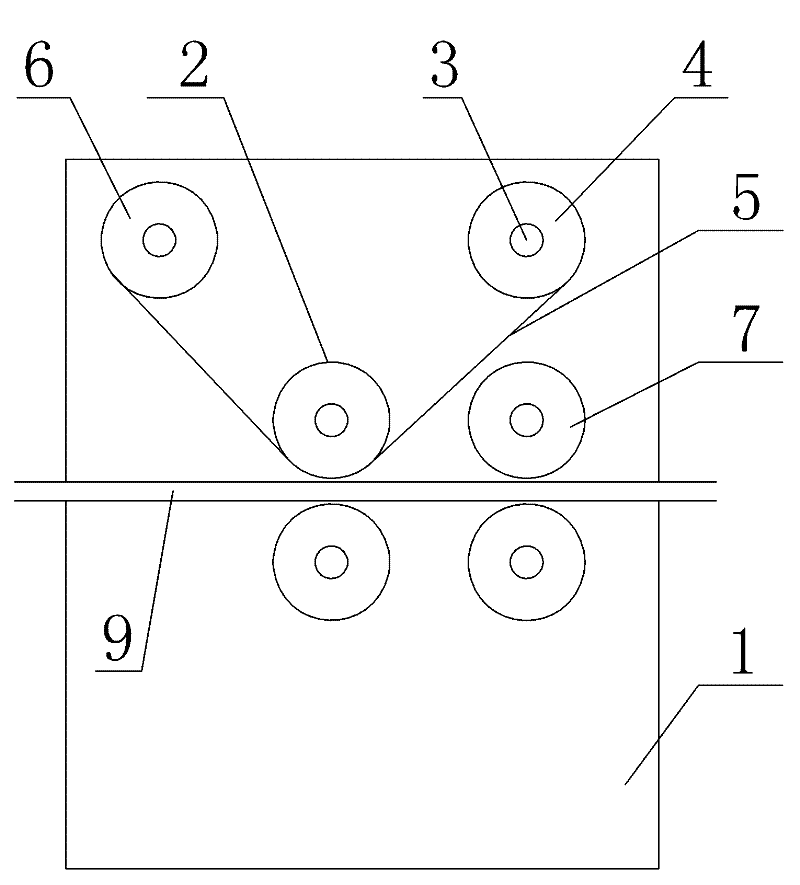

[0018] Such as figure 1 As shown, the optical cable printing machine has a work panel 1 vertically fixed on the ground, on the same side of the work panel 1, a pair of embossing wheels 2 whose axes are perpendicular to the work panel 1 are arranged, and the optical cable 9 enters the embossing wheel. A pair of guide wheels 7 on one side of the wheel 2, a fixed shaft 3 parallel to the axis of the embossing wheel 2 and fixed on the working panel 1, and a printing plate 4 sleeved on the fixed shaft 3 are set on the printing plate 4 for printing on the optical cable. 9. The printing tape 5 for printing on the surface and the take-up reel 6 that coils up the used printing tape 5 again. The two embossing wheels 2 are set up and down opposite each other, and the axis of the guide wheel 7 is parallel to the embossing wheel 2 axes.

[0019] In the present invention, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com