Vibration generating device

A technology of vibration generation and vibrating parts, applied in electromechanical devices, fluids using vibration, electrical components, etc., can solve problems such as reducing the overall structural limit, reducing the size of the vibrating body, and reducing the size of the spring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

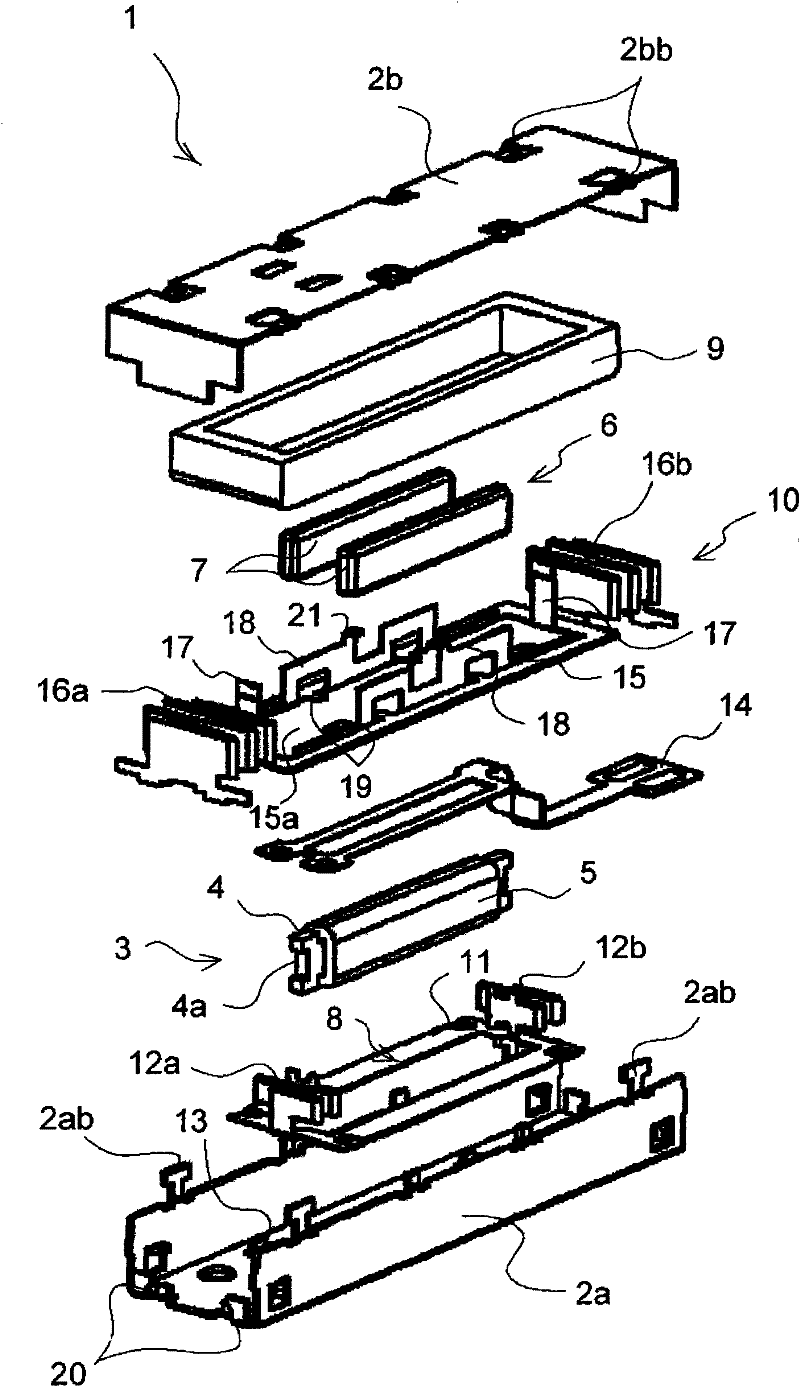

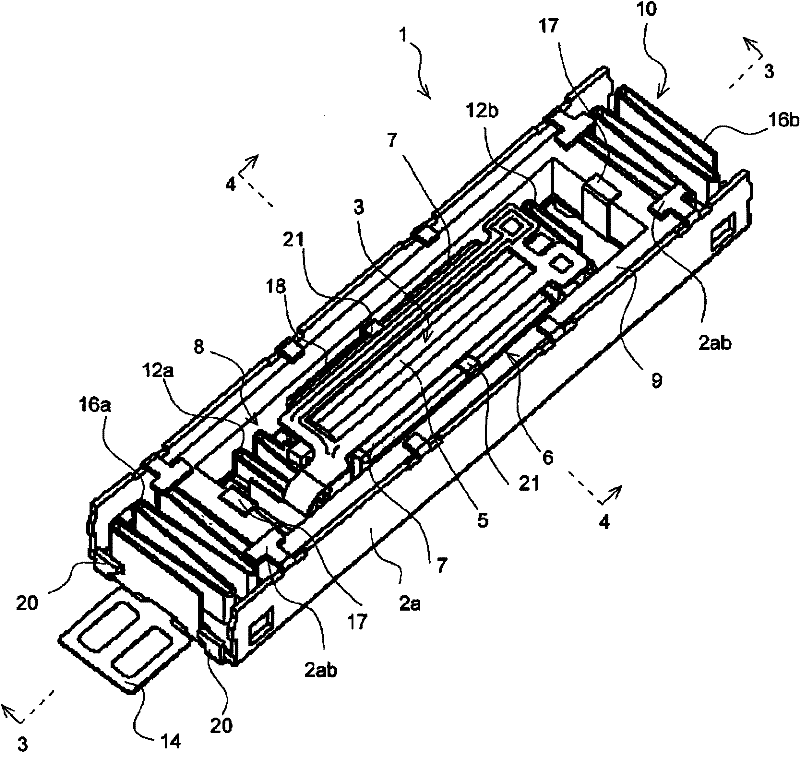

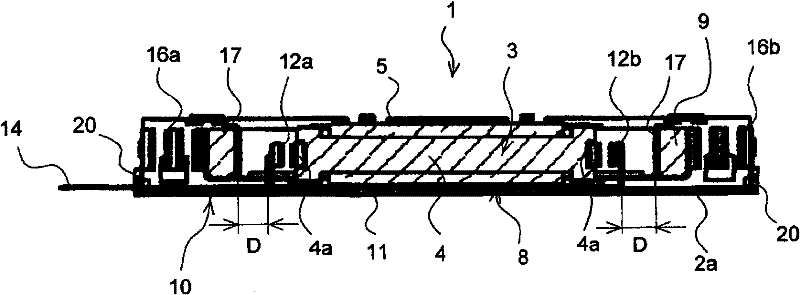

[0036] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

[0037] Figure 1 to Figure 5 An embodiment of the present invention is shown.

[0038] The vibration generating device 1 of the present embodiment is installed in a flat hollow rectangular parallelepiped frame 2. figure 1 Each of the components shown is formed to generate large vibrations of two frequencies.

[0039] In the present embodiment, the casing 2 is provided with: a first vibrator 3 wound with a coil 5 around the outer peripheral surface of the iron core 4, and vibrating by a magnetic field generated by the coil 5; A pair of magnets 7, 7 with the same poles facing each other on both sides of a vibrating element 3; The two ends) are supported to vibrate freely; the second vibrator 9, which is connected to the magnetic field forming part 6, is subjected to the reaction force of the interaction between the magnetic field generated by the coil 5 and the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com