Mold and injection molding apparatus

A mold and molding cavity technology, which is applied in the field of injection molding machines, can solve problems such as prolonging the time for product sample delivery and mass production, reducing production yield, and air bubbles in semi-finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

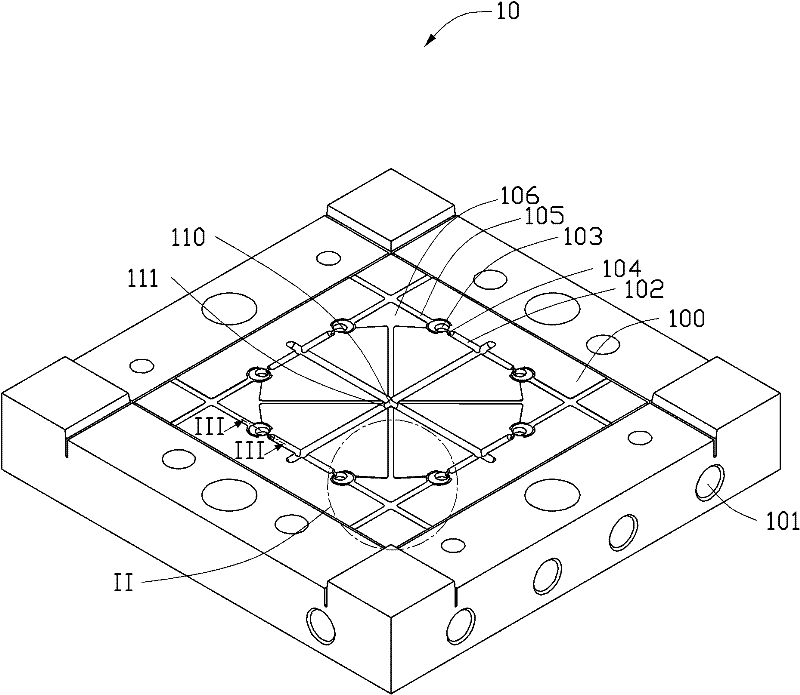

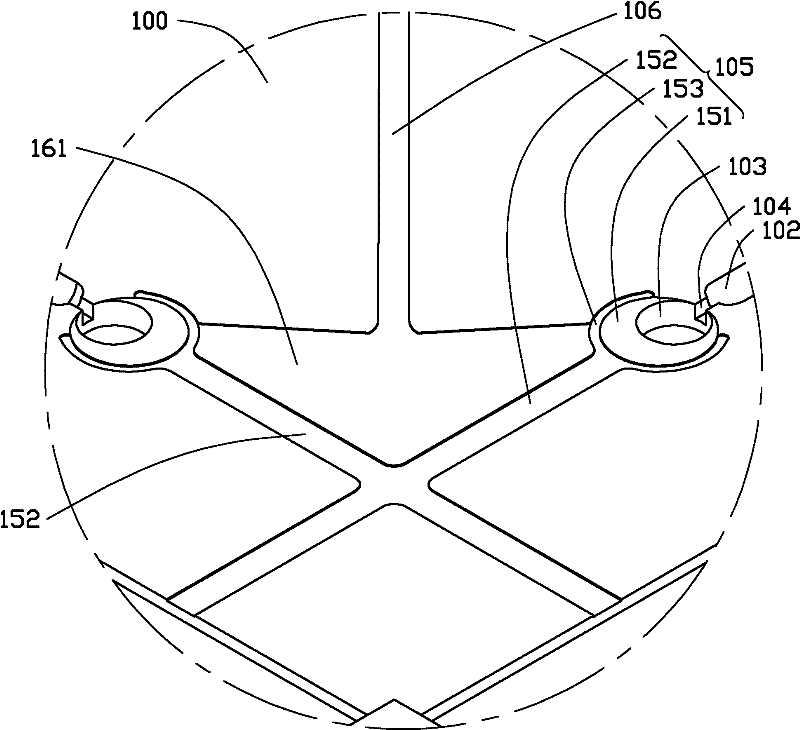

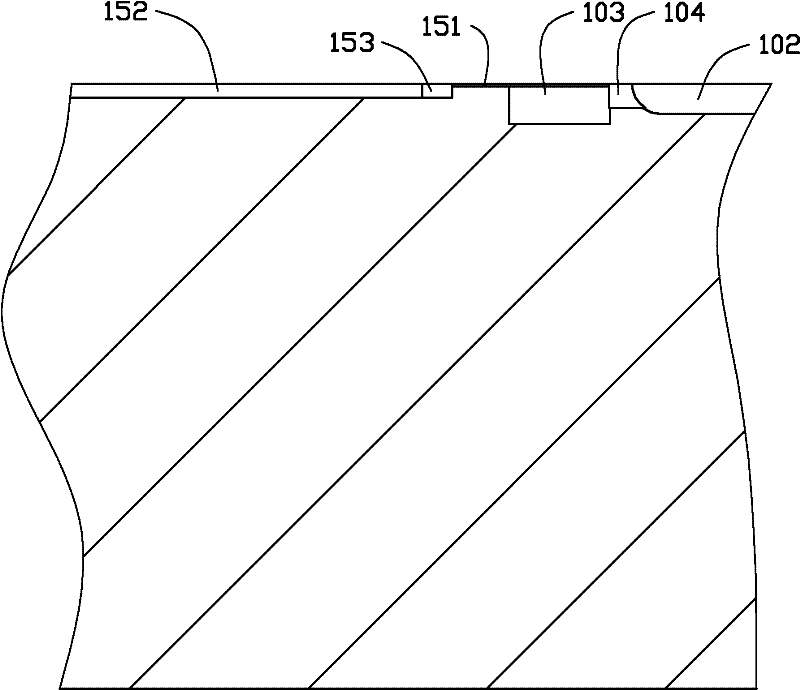

[0026] see figure 1 , A mold 10 provided by an embodiment of the present invention includes a parting surface 100 , a sprue 110 and a plurality of cooling channels 101 . The parting surface 100 is provided with 8 runners 102 (hereinafter referred to as runners 102 ), 8 molding cavities 103 , 8 gates 104 , 8 main exhaust slots 105 and 4 secondary exhaust slots 106 . For the convenience of description, only one of the above-mentioned components is used to illustrate the embodiment of the present invention. It can be understood that the present invention is not limited to the implementation of the above number of elements, and the specific number can be determined according to actual design and needs.

[0027] The cooling channel 101 is used for passing a cooling liquid (not shown in the figure) to cool the mold 10 . The branch channel 102 communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com