Preparation method of inner container of automobile tail pipe

A liner and tailpipe technology, which is applied in mechanical equipment, vehicle parts, noise reduction devices, etc., can solve problems such as difficult operation, multiple mold settings, and easy to leave cuts, so as to save processes and molds, improve processing efficiency, and guarantee The effect of drawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0027] The preparation method of the automobile tailpipe liner provided by the invention, the preparation steps comprise:

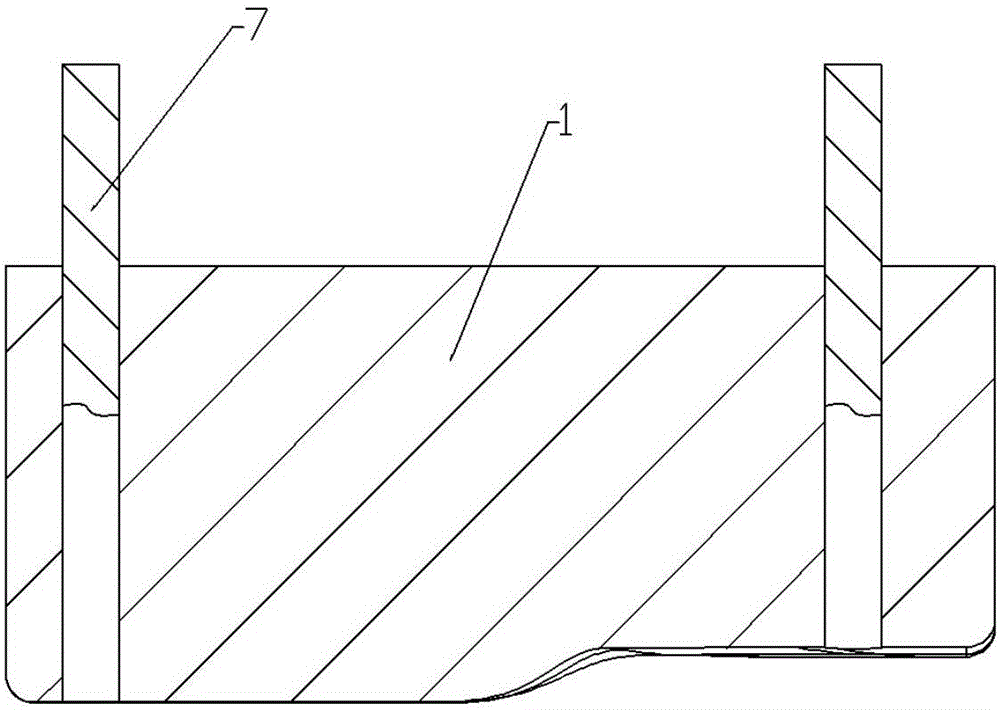

[0028] (1) First, according to the finished product size and area requirements of the tailpipe liner of the automobile, cut out the stainless steel liner raw material plate, the specific plate structure is as attached Figure 4 As shown: the raw material of the stainless steel liner is located at both ends of the length direction of the finished liner, and an extension block 12 is respectively provided, and a positioning hole 12.1 is arranged on the extension block;

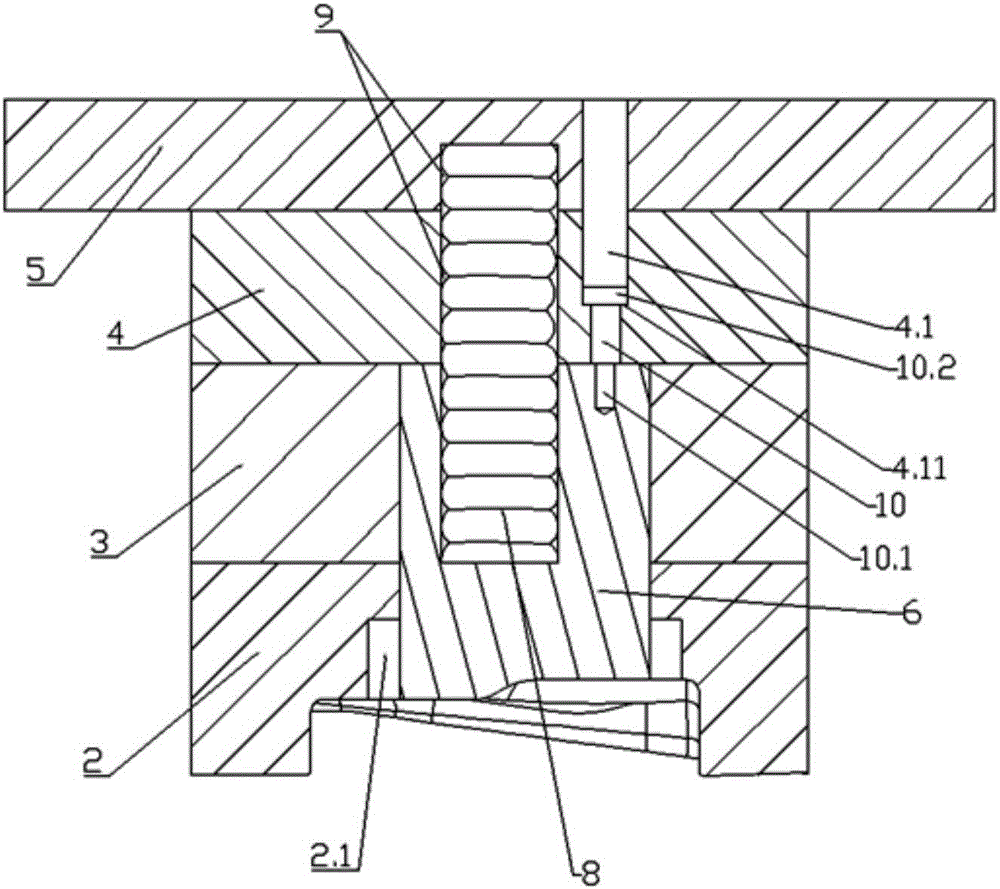

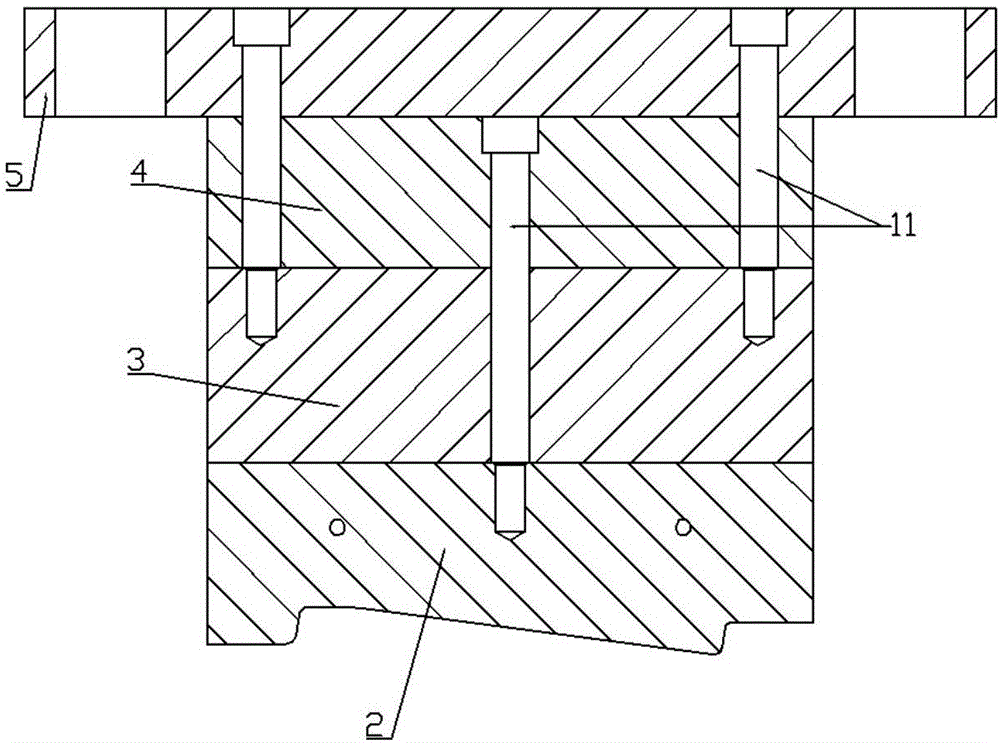

[0029] (2) Place the stainless steel liner raw material cut in step (1) in the drawing die; Figure 1-3 As shown: the drawing die includes an upper die assembly and a lower punch 1, and the upper die assembly includes an upper die 2, a first pressing plate 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com